In short, CNC machining is the preferred method for manufacturing Teflon (PTFE) parts because it masterfully sidesteps the material's fatal flaw: its intolerance to heat. Unlike injection molding or 3D printing, CNC machining is a subtractive process that provides exceptional precision and accommodates complex designs without melting the material, which would cause thermal degradation and component failure.

The core issue is that Teflon's unique molecular structure, which gives it low friction and chemical resistance, also causes it to have extremely high melt viscosity and poor flow. CNC machining is the ideal solution because it carves the final shape from a solid block, avoiding the problematic melting stage entirely.

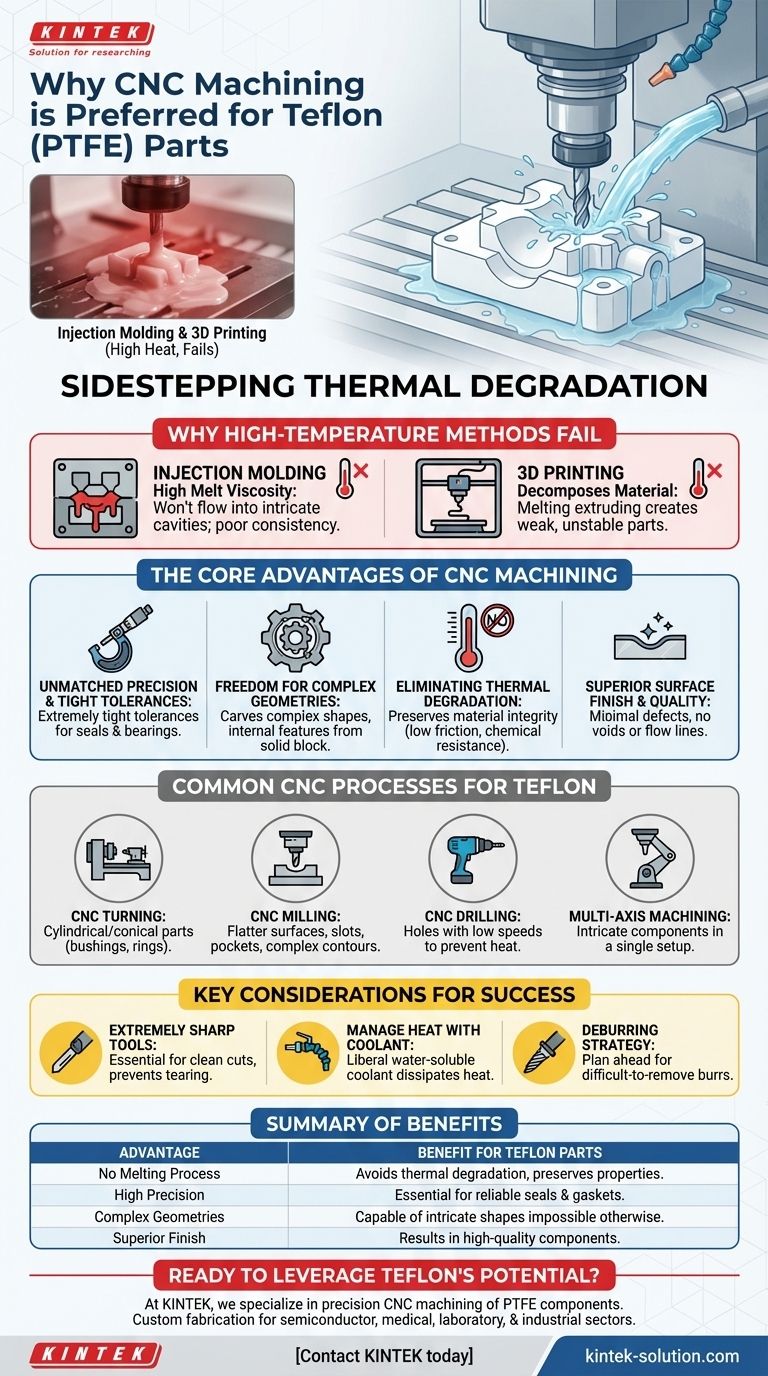

Why High-Temperature Methods Fail

The Challenge of Injection Molding

Teflon's high melt viscosity means it does not flow like a typical thermoplastic when heated. This makes it nearly impossible to force into the intricate cavities of a mold with any degree of accuracy or consistency.

The Limitations of 3D Printing

Similarly, 3D printing methods that rely on melting and extruding material are unsuitable for PTFE. The process would decompose the material before it could be properly formed, resulting in a weak and dimensionally unstable part.

The Core Advantages of CNC Machining

Unmatched Precision and Tight Tolerances

CNC machining works by precisely removing material with computer-controlled cutting tools. This allows for the creation of parts with extremely tight tolerances and high repeatability, which is critical for components like seals, gaskets, and bearings.

Freedom for Complex Geometries

Because the process carves from a solid block, it can produce highly complex shapes, internal features, and intricate contours that would be impossible with other methods. Multi-axis CNC machines can handle even the most demanding designs with exceptional accuracy.

Eliminating Thermal Degradation

The most critical advantage is the avoidance of high heat. While heat is generated during cutting, it can be carefully managed with proper speeds, feeds, and coolants. This preserves Teflon's material integrity, ensuring its desirable properties of low friction and chemical resistance remain intact.

Superior Surface Finish and Quality

CNC machining, when performed correctly, produces parts with a smooth surface finish and minimal defects. The controlled cutting process avoids the voids, sinks, or flow lines often associated with molding, leading to a higher-quality final component.

Common CNC Processes for Teflon

CNC Turning

This process is ideal for creating cylindrical or conical parts like bushings, rings, and seals. The Teflon workpiece rotates while a stationary cutting tool removes material.

CNC Milling

Milling uses a rotating cutting tool to shape a stationary workpiece. It is used to create flatter surfaces, slots, pockets, and complex 3D contours, making it one of the most versatile methods for Teflon parts.

CNC Drilling

This is a straightforward process for creating holes. However, with Teflon, it requires low cutting speeds and controlled feed rates to prevent heat buildup and melting.

Multi-Axis and 5-Axis Machining

For the most intricate components, multi-axis machining allows the cutting tool to approach the workpiece from multiple directions simultaneously. This enables the creation of highly complex geometries in a single setup, maximizing both efficiency and precision.

Key Considerations and Pitfalls

The Need for Extremely Sharp Tools

Teflon is a soft material that can deform or tear rather than cut cleanly if dull tools are used. Very sharp cutting tools are essential to achieve a clean cut and maintain dimensional accuracy.

Managing Heat with Coolant

Even without a melting process, friction from cutting generates heat that can cause Teflon to warp. A liberal application of a water-soluble coolant is crucial to dissipate this heat and prevent deformation.

The Challenge of Deburring

Machining Teflon often produces fine, stringy burrs along cut edges that can be difficult to remove. A deburring strategy must be planned in advance, which may involve manual trimming, sanding, or even freezing the part to make the burrs brittle and easier to break off.

How to Apply This to Your Project

When designing or sourcing a Teflon part, the specific CNC approach is dictated by your end goal.

- If your primary focus is high-performance seals or gaskets: Prioritize CNC turning for its ability to hold tight diametrical tolerances and create excellent surface finishes for sealing applications.

- If your primary focus is complex structural components: Specify 5-axis CNC milling to accommodate intricate features, internal channels, and complex curvatures in a single, precise operation.

- If your primary focus is cost-effective, simple parts: Standard CNC milling and drilling are perfectly suitable, but ensure your manufacturing partner uses sharp tooling and proper coolant to avoid quality issues.

Ultimately, choosing CNC machining is the definitive way to unlock Teflon's high-performance properties without compromising the integrity of your design.

Summary Table:

| Advantage | Benefit for Teflon Parts |

|---|---|

| No Melting Process | Avoids thermal degradation, preserving material properties like chemical resistance and low friction. |

| High Precision & Tight Tolerances | Essential for creating reliable seals, gaskets, and bearings. |

| Complex Geometries | Capable of producing intricate shapes, internal features, and contours impossible with other methods. |

| Superior Surface Finish | Results in high-quality components with minimal defects. |

Ready to leverage the full potential of Teflon for your application?

At KINTEK, we specialize in the precision CNC machining of PTFE components. Our expertise ensures your parts—from custom seals and liners to complex labware—are manufactured to the highest standards, preserving the material's integrity and meeting your exact specifications.

We serve the semiconductor, medical, laboratory, and industrial sectors with custom fabrication from prototypes to high-volume orders.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability