In the aerospace industry, component failure is not an option. PTFE (Polytetrafluoroethylene) washers are used because they provide unparalleled reliability in environments with extreme temperature shifts, high pressures, and corrosive chemicals. Their unique combination of properties ensures that critical systems from engines to hydraulics function safely under the harshest conditions imaginable.

The core reason for PTFE's prevalence in aerospace is not a single characteristic, but its rare ability to simultaneously withstand a wide spectrum of environmental abuses. It is one of the few materials that reliably performs across extreme temperatures, aggressive fluids, and high-pressure differentials, making it indispensable for safety-critical applications.

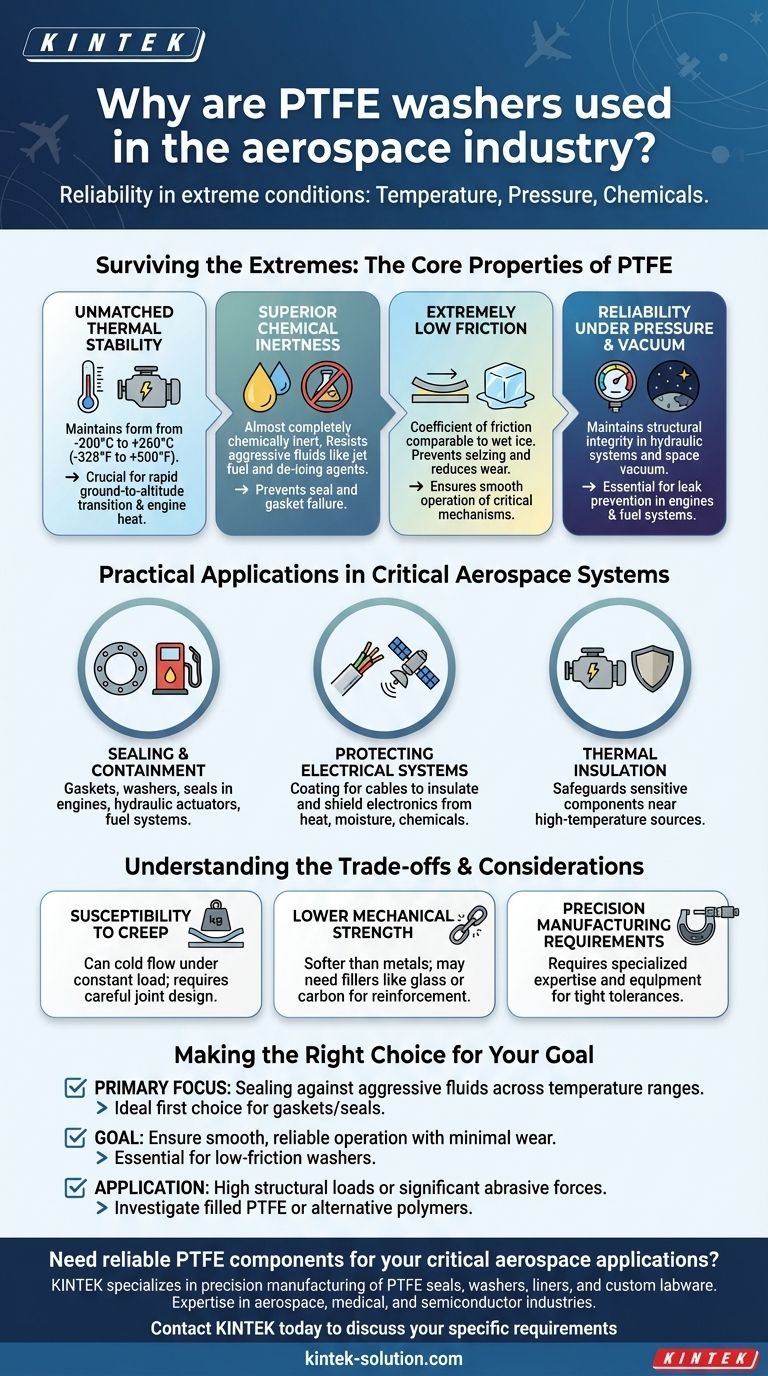

Surviving the Extremes: The Core Properties of PTFE

The demands of aerospace operation—from ground level to high-altitude flight and the vacuum of space—push materials to their absolute limits. PTFE is specified because its inherent properties directly counter these challenges.

Unmatched Thermal Stability

PTFE washers maintain their form and function across an exceptionally broad temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This is critical for components that must endure the rapid transition from ground-level heat to the freezing cold of high altitudes, as well as the intense heat generated by aircraft engines.

Superior Chemical Inertness

Aerospace systems rely on aggressive fluids like hydraulic oils, jet fuel, and de-icing agents. PTFE is almost completely chemically inert, meaning it will not degrade or corrode when exposed to these substances.

This resistance prevents seal and gasket failure, which is crucial for maintaining the integrity of fuel and hydraulic systems.

The Benefit of Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, comparable to wet ice on wet ice.

In aerospace applications, this property prevents the seizing of moving parts and reduces wear and tear over time. It also helps prevent the buildup of debris in critical mechanisms, ensuring smooth and reliable operation.

Reliability Under Pressure and Vacuum

From pressurized hydraulic systems to the vacuum of space, PTFE components maintain their structural integrity.

Spring-energized PTFE seals, for example, are specifically designed to provide a reliable seal even when experiencing significant pressure and temperature fluctuations, preventing leaks in critical engine and fuel systems.

Practical Applications in Critical Aerospace Systems

PTFE is not just used for washers; its properties make it essential for a range of components where reliability directly impacts safety and performance.

Sealing and Containment

The most common application is in seals, gaskets, and washers. These components are fundamental to the operation of aircraft engines, hydraulic actuators, and fuel delivery systems, where preventing leaks is a mission-critical requirement.

Protecting Electrical Systems

As a superior electrical insulator, PTFE is used to coat cables and wires. This protection is vital for maintaining reliable communication and control systems during flight.

The coating shields sensitive electronics from heat, moisture, and chemical exposure, preventing short circuits and signal degradation.

Thermal Insulation

PTFE's heat resistance makes it an effective thermal insulator. It is often used to safeguard sensitive components located near high-temperature sources like engines and exhaust systems, preventing heat damage and ensuring their operational longevity.

Understanding the Trade-offs and Considerations

While PTFE's benefits are significant, it is not a universal solution. A clear-eyed understanding of its limitations is crucial for proper engineering design.

Susceptibility to Creep

Under a constant, sustained load, PTFE can be subject to "creep" or cold flow, meaning it can slowly deform over time. This must be accounted for in the design of joints and seals to ensure long-term performance.

Lower Mechanical Strength

Compared to metals or other engineered polymers like PEEK, PTFE is a relatively soft material with lower tensile strength and abrasion resistance. For this reason, it is often reinforced with fillers like glass, carbon, or graphite to improve its mechanical properties for specific applications.

Precision Manufacturing Requirements

The exacting standards of the aerospace industry require components manufactured with extreme precision. While PTFE can be machined to tight tolerances, this requires specialized expertise and equipment, which can influence project costs and timelines.

Making the Right Choice for Your Goal

Your decision to specify PTFE should be driven by the specific environmental and mechanical stresses the component will face.

- If your primary focus is sealing against aggressive fluids across wide temperature ranges: PTFE is an ideal first choice for gaskets and seals in fuel or hydraulic systems due to its chemical inertness and thermal stability.

- If your component must ensure smooth, reliable operation with minimal wear: The low-friction nature of PTFE washers makes them essential for reducing maintenance and increasing the lifespan of moving assemblies.

- If your application involves high structural loads or significant abrasive forces: Pure PTFE may not be sufficient. In this case, investigate filled PTFE compounds or alternative high-performance polymers.

Ultimately, PTFE's unique combination of properties makes it a foundational material for ensuring the reliability and safety of modern aerospace systems.

Summary Table:

| Key Property | Benefit in Aerospace |

|---|---|

| Thermal Stability (-200°C to +260°C) | Reliable performance from ground heat to high-altitude cold. |

| Chemical Inertness | Resists degradation from fuels, hydraulic oils, and de-icing agents. |

| Low Friction | Reduces wear and prevents seizing in moving parts. |

| Pressure/Vacuum Reliability | Maintains seal integrity in hydraulic systems and space environments. |

Need reliable PTFE components for your critical aerospace applications?

KINTEK specializes in the precision manufacturing of PTFE seals, washers, liners, and custom labware. We understand the extreme demands of the aerospace, medical, and semiconductor industries. Our expertise ensures your components meet the highest standards for thermal stability, chemical resistance, and performance under pressure.

We offer custom fabrication from prototypes to high-volume orders, delivering the reliability your projects demand.

Contact KINTEK today to discuss your specific requirements and let our expertise enhance your design's safety and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech