In aerospace, PTFE washers are indispensable for their unique combination of properties that directly address the industry's most demanding challenges. They are exceptionally lightweight yet durable, exhibit a very low coefficient of friction, remain stable across extreme temperatures, are inert to corrosive chemicals, and serve as excellent electrical insulators.

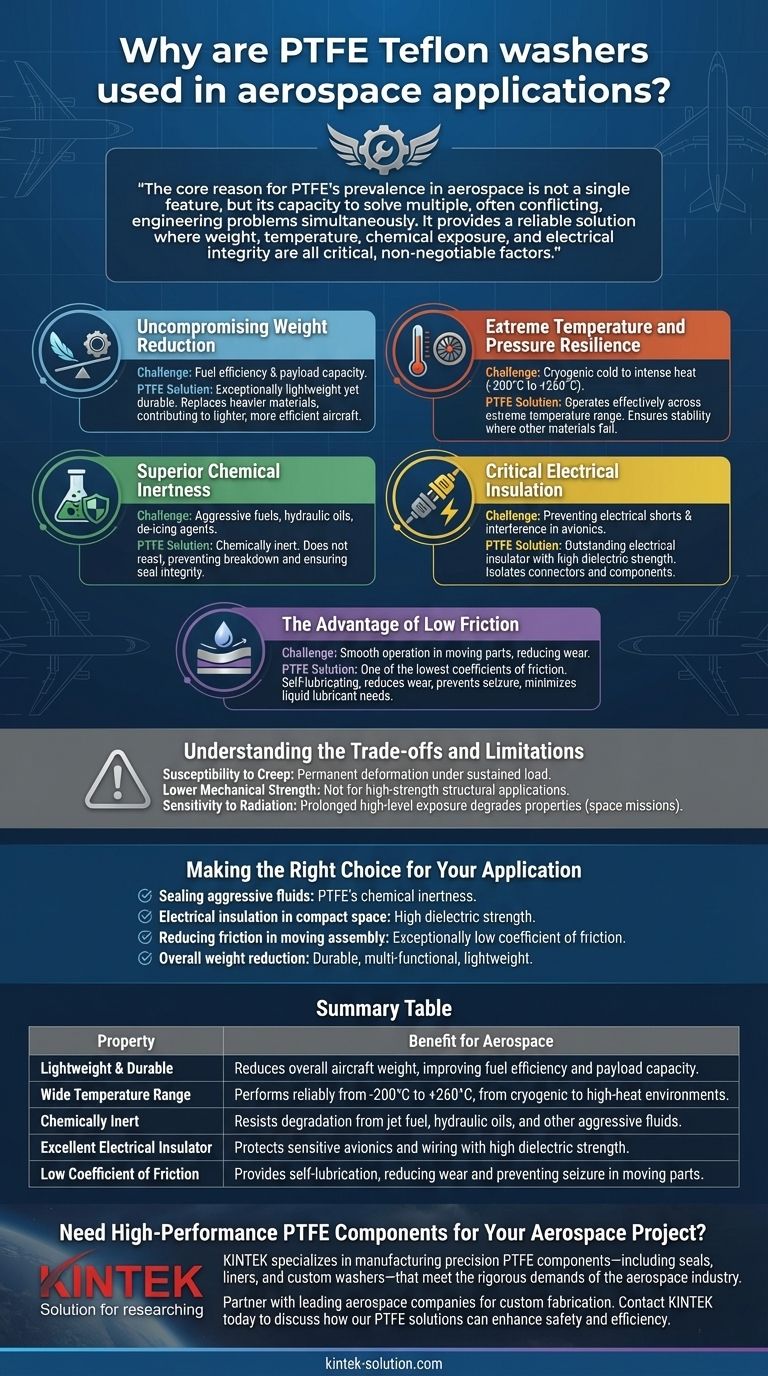

The core reason for PTFE's prevalence in aerospace is not a single feature, but its capacity to solve multiple, often conflicting, engineering problems simultaneously. It provides a reliable solution where weight, temperature, chemical exposure, and electrical integrity are all critical, non-negotiable factors.

The Core Aerospace Challenges PTFE Solves

To understand the value of PTFE, we must first look at the fundamental problems aerospace engineers face. A material's success is measured by how effectively it solves these challenges.

Uncompromising Weight Reduction

Every gram on an aircraft impacts fuel efficiency and payload capacity. PTFE is a remarkably lightweight yet durable polymer.

This allows it to replace heavier metal or composite washers in many applications without sacrificing performance, contributing directly to a lighter, more efficient aircraft.

Extreme Temperature and Pressure Resilience

Aerospace components must function reliably from the cryogenic cold of high altitude or space to the intense heat of an engine compartment.

PTFE washers operate effectively within an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F), ensuring stability and performance where other materials would fail.

Superior Chemical Inertness

Aircraft systems rely on aggressive fluids, including jet fuel, hydraulic oils, and de-icing agents. These substances can degrade many materials over time.

PTFE is chemically inert, meaning it does not react with these substances. This prevents the washer from breaking down, ensuring the integrity of critical seals in fuel lines and hydraulic systems.

Critical Electrical Insulation

Modern aircraft are complex electronic systems, with miles of wiring and sensitive avionics. Preventing electrical shorts and interference is paramount for safety.

PTFE is an outstanding electrical insulator with high dielectric strength. It is used to isolate electrical connectors, terminals, and components, ensuring the reliability of fly-by-wire and communication systems.

The Advantage of Low Friction

Assemblies with moving parts, such as control surface linkages or landing gear mechanisms, require smooth, reliable operation.

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property reduces wear and prevents parts from seizing, often eliminating the need for liquid lubricants that could freeze, evaporate, or attract contaminants.

Understanding the Trade-offs and Limitations

While incredibly useful, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations in certain contexts.

Susceptibility to Creep

Under a constant, sustained load (especially at elevated temperatures), PTFE can be subject to "creep," a slow, permanent deformation over time. This must be carefully considered in the design of bolted joints to ensure proper tension is maintained.

Lower Mechanical Strength

Compared to metals, PTFE is a relatively soft material. It is not suitable for high-strength structural applications. Its primary roles are as a washer, bearing, seal, or insulator—not as a load-bearing fastener itself.

Sensitivity to Radiation

For space applications outside of Earth's protective atmosphere, prolonged exposure to high levels of radiation can cause the PTFE polymer chain to break down, degrading its mechanical properties. For long-duration space missions, radiation-hardened materials may be required.

Making the Right Choice for Your Application

Selecting a PTFE washer is a strategic decision based on the primary problem you need to solve within your design.

- If your primary focus is sealing aggressive fluids: PTFE's chemical inertness makes it the definitive choice for creating reliable seals in fuel, hydraulic, and chemical delivery systems.

- If your primary focus is electrical insulation in a compact space: PTFE's high dielectric strength provides effective and lightweight isolation between sensitive electronic components.

- If your primary focus is reducing friction in a moving assembly: The exceptionally low coefficient of friction of PTFE ensures smooth, self-lubricating operation and significantly reduces wear.

- If your primary focus is overall weight reduction: PTFE provides a durable, multi-functional solution that can replace heavier components in countless non-structural roles.

Ultimately, PTFE washers are a cornerstone of modern aerospace design because they solve multiple critical engineering problems with a single, reliable material.

Summary Table:

| Property | Benefit for Aerospace |

|---|---|

| Lightweight & Durable | Reduces overall aircraft weight, improving fuel efficiency and payload capacity. |

| Wide Temperature Range | Performs reliably from -200°C to +260°C, from cryogenic to high-heat environments. |

| Chemically Inert | Resists degradation from jet fuel, hydraulic oils, and other aggressive fluids. |

| Excellent Electrical Insulator | Protects sensitive avionics and wiring with high dielectric strength. |

| Low Coefficient of Friction | Provides self-lubrication, reducing wear and preventing seizure in moving parts. |

Need High-Performance PTFE Components for Your Aerospace Project?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom washers—that meet the rigorous demands of the aerospace industry. Our expertise ensures your designs benefit from the critical properties of PTFE, such as extreme temperature resilience, chemical inertness, and superior electrical insulation.

We partner with leading aerospace companies to deliver custom fabrication from prototypes to high-volume production, guaranteeing quality and reliability in every part.

Contact KINTEK today to discuss how our PTFE solutions can enhance the safety and efficiency of your aerospace systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments