In short, PTFE slide bearings are superior because they replace high-maintenance mechanical systems with a simple, material-based solution. Their inherently low friction, self-lubricating properties, and resistance to environmental degradation allow them to accommodate structural movement more reliably and with less stress than conventional expansion plates and rollers.

The fundamental advantage of PTFE is that it solves the problem of structural movement through material science, not mechanics. Instead of relying on rolling or greased parts that can seize, corrode, or collect debris, PTFE provides a smooth, maintenance-free sliding surface that ensures consistent performance over the life of the structure.

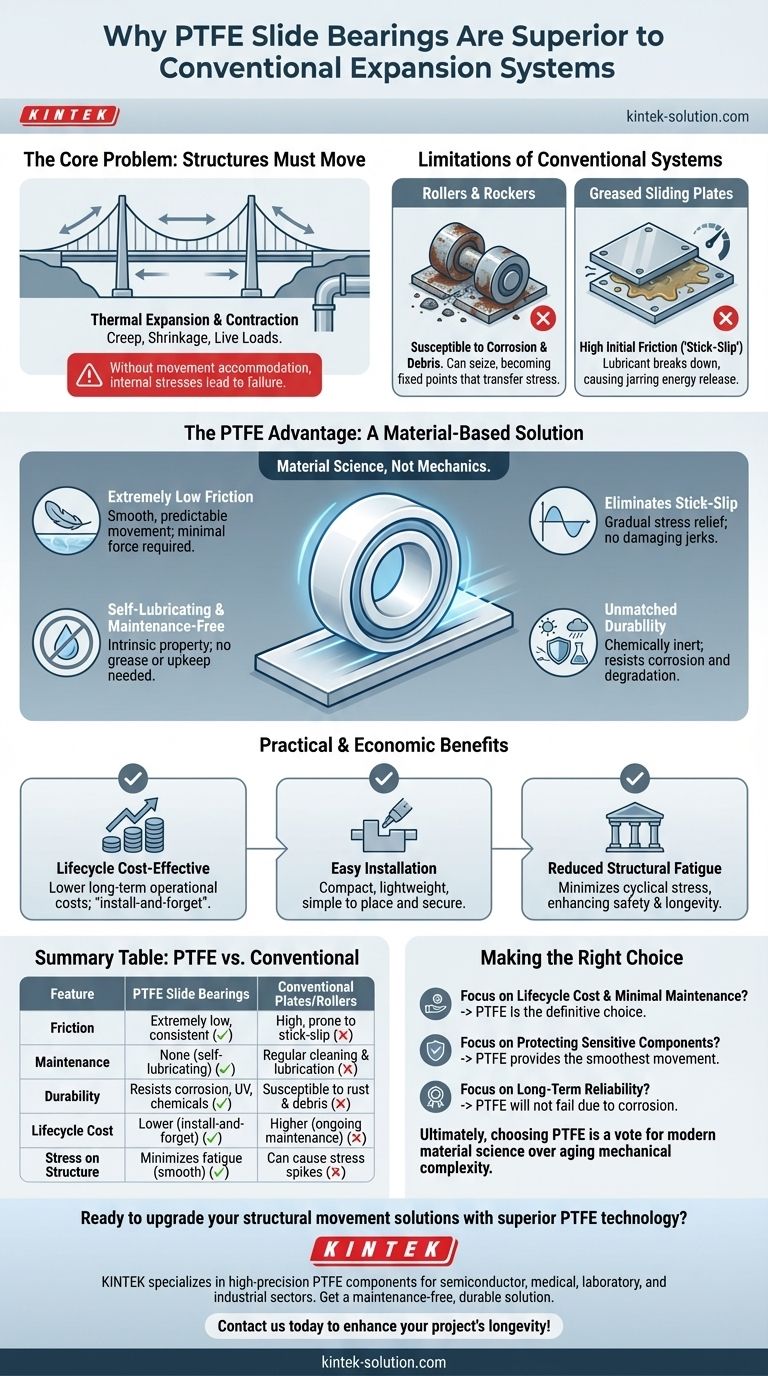

The Core Problem: Why Structures Need to Move

To understand the value of PTFE bearings, we must first recognize that large structures like bridges, pipelines, and buildings are not static. They are designed to move in controlled ways.

The Impact of Thermal Expansion

The primary force at play is thermal expansion and contraction. As ambient temperatures change, construction materials expand or shrink. Without a way to accommodate this movement, immense internal stresses would build up, leading to cracks, buckling, and eventual failure.

Other Sources of Movement

Beyond temperature, structures also move due to material creep and shrinkage, as well as deflection from live loads (like traffic on a bridge). An expansion bearing's job is to allow for all these movements without transferring harmful stress between structural components.

The Limitations of Conventional Systems

Traditional methods managed this movement with mechanical assemblies that, while functional, have significant inherent weaknesses.

Rollers and Rockers

These systems use steel cylinders to allow one structural element to roll back and forth relative to another. Their main drawback is their susceptibility to corrosion and debris accumulation. Over time, rust or dirt can cause the rollers to seize, preventing movement and turning them into a fixed point that transfers, rather than relieves, stress.

Greased Sliding Plates

Another common method involves two steel plates with a layer of grease between them. This approach suffers from high initial friction, known as "stick-slip" action. A significant amount of stress must build before the plates break free and slide, causing a jarring release of energy. Furthermore, the lubricant can break down, squeeze out over time, or attract contaminants, drastically reducing its effectiveness.

The PTFE Advantage: A Material-Based Solution

PTFE (Polytetrafluoroethylene) slide bearings operate on a completely different principle. They leverage the unique properties of the material itself to create a near-perfect sliding surface.

Exceptionally Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material. This means very little force is required to initiate and sustain movement. The transition from static to dynamic states is smooth, preventing the stress build-up seen in greased plates.

Elimination of Stick-Slip

Because the friction is consistently low, PTFE bearings move smoothly and predictably. This eliminates the damaging stick-slip phenomenon, ensuring that stress is relieved gradually as it develops, which is far safer for the structure.

Self-Lubricating and Maintenance-Free

The low-friction nature of PTFE is an intrinsic property. It does not require grease or any other external lubricant. This makes the bearing self-lubricating and completely maintenance-free, a significant advantage over the lifecycle of the structure.

Unmatched Durability

PTFE is chemically inert and unaffected by weathering, moisture, and UV radiation. Unlike steel rollers or plates, it will not corrode or degrade when exposed to the elements, guaranteeing reliable performance for decades.

Understanding the Practical and Economic Benefits

The technical superiority of PTFE translates directly into practical and financial advantages during construction and operation.

Lifecycle Cost-Effectiveness

While conventional systems might seem cheaper initially, their need for regular inspection, cleaning, and re-lubrication adds significant long-term operational costs. PTFE's install-and-forget nature makes it far more cost-effective over the structure's lifespan.

Ease of Installation

PTFE bearings are compact, lightweight, and simple. They consist of a PTFE sheet bonded to a backing plate, which is easily placed and secured. This is far less complex than aligning and installing heavy, multi-part roller assemblies.

Reduced Structural Fatigue

By ensuring smooth, low-resistance movement, PTFE bearings minimize the cyclical stress transferred to columns, piers, and foundations. This reduces long-term material fatigue and enhances the overall durability and safety of the entire structure.

Making the Right Choice for Your Application

The decision between bearing types depends on prioritizing long-term performance and reliability.

- If your primary focus is lifecycle cost and minimal maintenance: PTFE is the definitive choice due to its self-lubricating, corrosion-proof design that eliminates operational expenses.

- If your primary focus is protecting sensitive components from stress: The low, consistent friction of PTFE provides the smoothest movement, preventing the damaging stress spikes caused by stick-slip in older systems.

- If your primary focus is long-term reliability in harsh environments: PTFE's chemical inertness and resistance to weathering ensure it will not fail due to corrosion or contamination like mechanical alternatives.

Ultimately, choosing PTFE bearings is a vote for modern material science over aging mechanical complexity.

Summary Table:

| Feature | PTFE Slide Bearings | Conventional Plates/Rollers |

|---|---|---|

| Friction | Extremely low, consistent | High, prone to stick-slip |

| Maintenance | None (self-lubricating) | Regular cleaning & lubrication |

| Durability | Resists corrosion, UV, chemicals | Susceptible to rust and debris |

| Lifecycle Cost | Lower (install-and-forget) | Higher (ongoing maintenance) |

| Stress on Structure | Minimizes fatigue from smooth movement | Can cause stress spikes |

Ready to upgrade your structural movement solutions with superior PTFE technology?

KINTEK specializes in manufacturing high-precision PTFE components, including custom slide bearings, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a maintenance-free, durable solution tailored to your specific needs—from prototypes to high-volume orders.

Contact us today to discuss how our PTFE bearings can enhance your project's longevity and reliability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments