To put it simply, PTFE extruded rods are exceptionally suitable for sealing applications because of their unique combination of properties. They are almost universally chemically inert, can withstand an extremely wide range of temperatures, and maintain their shape under pressure, which are the three most critical requirements for a reliable seal in demanding environments.

The core reason for PTFE's dominance in sealing is not just one superior property, but its rare ability to deliver elite performance across chemical, thermal, and mechanical stresses simultaneously. Where other materials might excel in one area but fail in another, PTFE provides a complete, high-endurance solution.

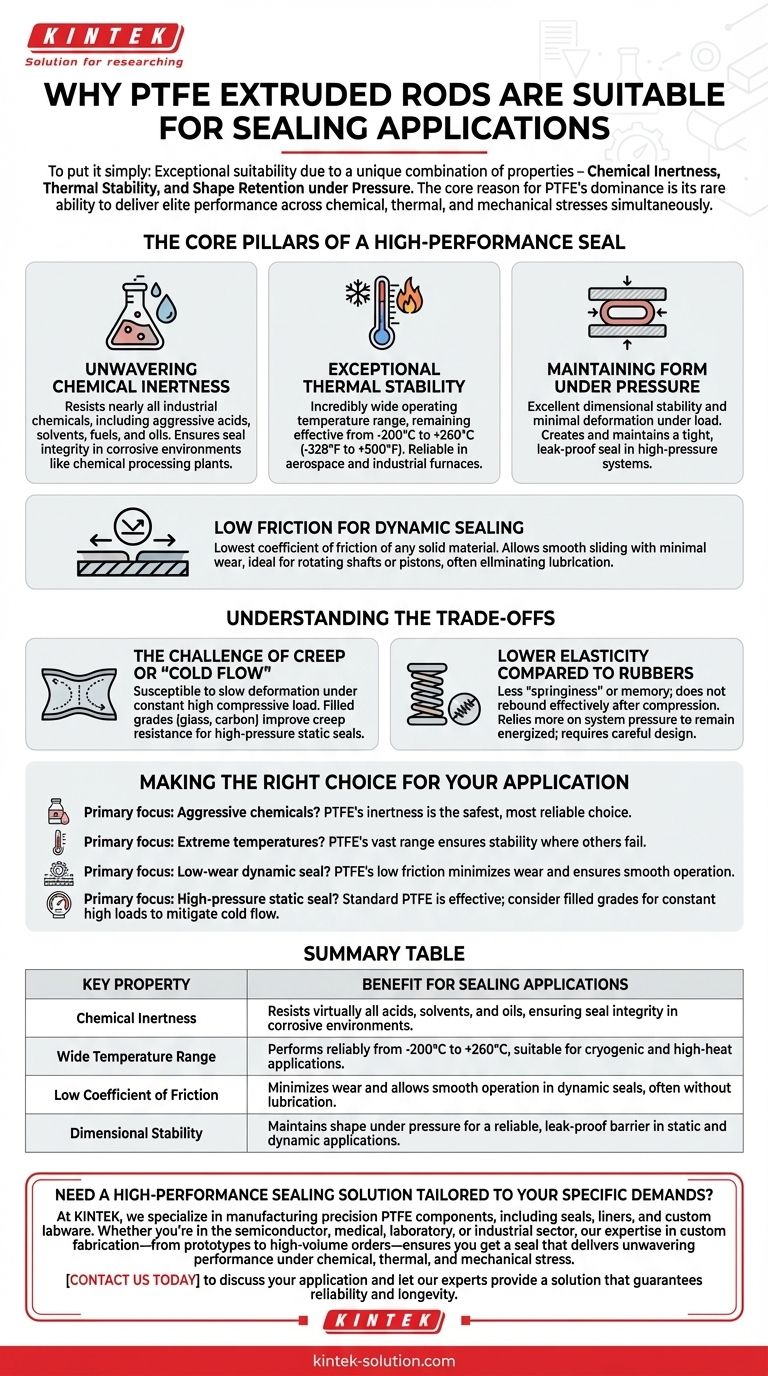

The Core Pillars of a High-Performance Seal

To understand why PTFE is such a powerful choice, we must first define what a high-performance seal is required to do. It must create a leak-proof barrier, survive its operating environment without degrading, and maintain its integrity for a long service life. PTFE's molecular structure directly addresses these needs.

Unwavering Chemical Inertness

A seal is often the first line of defense against aggressive media. If the seal material reacts with the substance it's containing, it will quickly swell, harden, or dissolve, leading to failure.

PTFE is resistant to nearly all industrial chemicals, including aggressive acids, solvents, fuels, and oils. This chemical inertness ensures the seal maintains its physical properties and continues to prevent leaks, even in the most corrosive environments like chemical processing plants.

Exceptional Thermal Stability

Seals are frequently used in applications involving extreme temperatures, from cryogenic systems to high-heat engines. A material must not become brittle in the cold or soft and weak in the heat.

PTFE has an incredibly wide operating temperature range, remaining effective from -200°C to +260°C (-328°F to +500°F). This ensures it retains its sealing capability and structural integrity whether it's used in aerospace applications or industrial furnaces.

Maintaining Form Under Pressure

The fundamental job of a gasket or seal is to conform to a surface and hold its shape under compressive force to block any path for leakage. A material that deforms or "creeps" over time will eventually fail.

PTFE exhibits excellent dimensional stability and minimal deformation under load. This property ensures it creates and maintains a tight, leak-proof seal, which is critical in high-pressure hydraulic systems or industrial piping.

Low Friction for Dynamic Sealing

In applications where parts move against the seal (dynamic seals), friction is a major enemy. High friction causes wear, generates heat, and can lead to jerky, uncontrolled movement.

With the lowest coefficient of friction of any solid material, PTFE allows components to slide smoothly across its surface with minimal wear. This makes it an ideal choice for O-rings and seals in rotating shafts or pistons, often eliminating the need for lubrication.

Understanding the Trade-offs

No material is perfect for every scenario. While PTFE's properties are remarkable, a technical advisor must also highlight its limitations to ensure proper application.

The Challenge of Creep or "Cold Flow"

While PTFE has good creep resistance for a fluoropolymer, it can be susceptible to cold flow. This is a slow deformation that can occur when the material is subjected to a constant, high compressive load over a long period.

For high-pressure static seals where long-term integrity is paramount, this must be considered in the design. Often, filled grades of PTFE (mixed with materials like glass or carbon) are used to significantly improve creep resistance.

Lower Elasticity Compared to Rubbers

Unlike elastomers like rubber, pure PTFE is not very elastic. It doesn't have the same "springiness" or memory, meaning it will not rebound to its original shape as effectively after being compressed.

This can make installation more challenging and means the seal relies more on system pressure to remain energized. Careful design of the seal groove or housing is essential to compensate for this characteristic.

Making the Right Choice for Your Application

Selecting the right material requires matching its properties to the primary demands of your task. PTFE offers a versatile solution, but its strengths are most pronounced in specific scenarios.

- If your primary focus is sealing against aggressive chemicals: PTFE's near-universal chemical inertness makes it the safest and most reliable choice.

- If your primary focus is performance in extreme temperatures: PTFE's vast operating temperature range ensures stability where most other plastics and elastomers would fail.

- If your primary focus is a low-wear dynamic seal: PTFE's unparalleled low coefficient of friction will minimize wear and ensure smooth operation.

- If your primary focus is a high-pressure static seal: Standard PTFE is very effective, but consider a filled grade if the application involves very high, constant loads to mitigate any risk of cold flow.

Ultimately, PTFE's value comes from its ability to solve the most challenging sealing problems where failure is not an option.

Summary Table:

| Key Property | Benefit for Sealing Applications |

|---|---|

| Chemical Inertness | Resists virtually all acids, solvents, and oils, ensuring seal integrity in corrosive environments. |

| Wide Temperature Range | Performs reliably from -200°C to +260°C, suitable for cryogenic and high-heat applications. |

| Low Coefficient of Friction | Minimizes wear and allows smooth operation in dynamic seals, often without lubrication. |

| Dimensional Stability | Maintains shape under pressure for a reliable, leak-proof barrier in static and dynamic applications. |

Need a high-performance sealing solution tailored to your specific demands?

At KINTEK, we specialize in manufacturing precision PTFE components, including seals, liners, and custom labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a seal that delivers unwavering performance under chemical, thermal, and mechanical stress.

Contact us today to discuss your application and let our experts provide a solution that guarantees reliability and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support