To be direct, PTFE envelope gaskets are suitable for FDA applications because the Polytetrafluoroethylene (PTFE) material itself is recognized as food-grade. It is chemically inert and non-toxic, ensuring it does not contaminate the food, beverage, or pharmaceutical products it contacts, thereby meeting strict FDA regulations for cleanliness and safety.

The suitability of PTFE envelope gaskets for sensitive FDA-regulated applications hinges on a simple principle: they combine the unparalleled chemical inertness and purity of a PTFE surface with the mechanical strength and resilience of a separate core material.

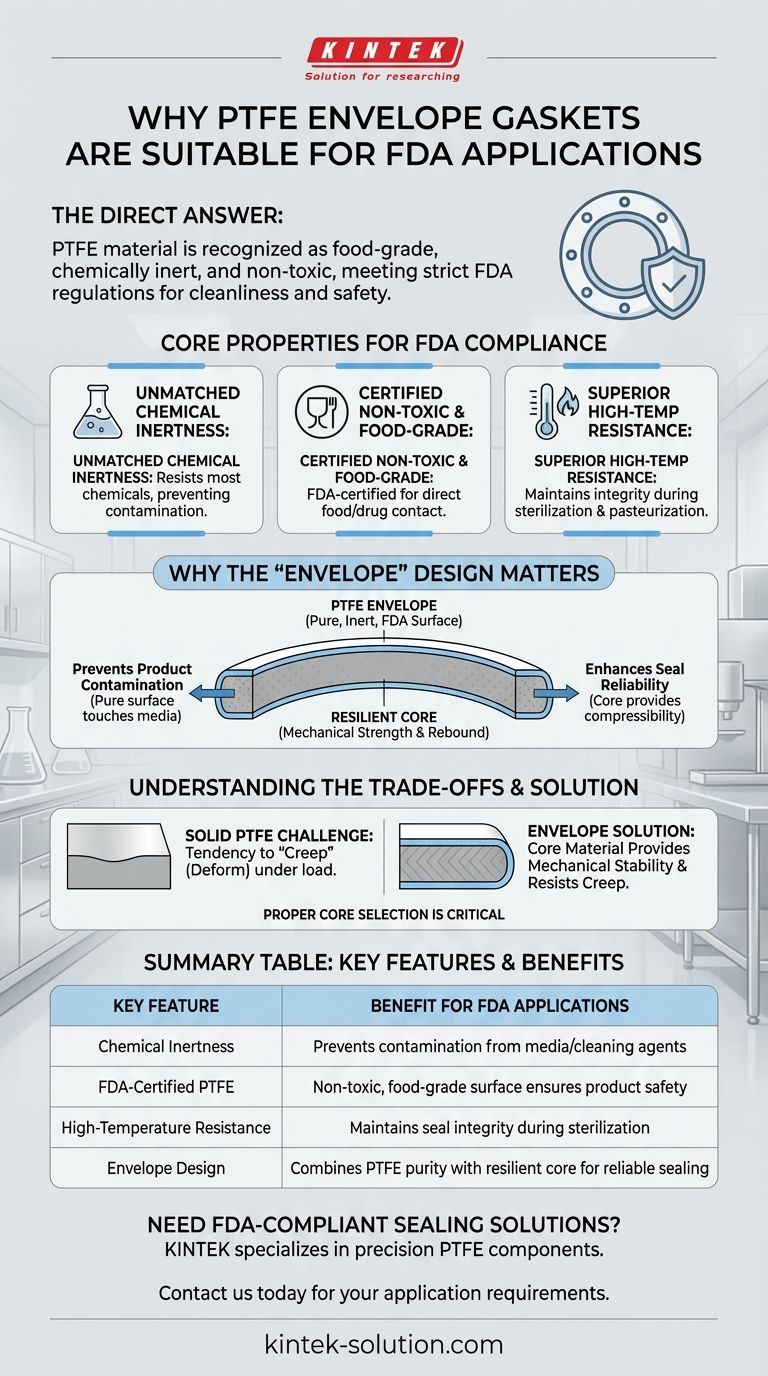

The Core Properties That Ensure FDA Compliance

The reason PTFE is a trusted material in regulated industries comes down to a unique combination of intrinsic properties. These characteristics ensure that the gasket will not compromise the integrity or safety of the end product.

Unmatched Chemical Inertness

PTFE is renowned for its exceptional chemical resistance. It does not react with or degrade when exposed to the vast majority of industrial chemicals, cleaning agents, or active pharmaceutical ingredients.

This inertness is critical for preventing contamination, ensuring that the gasket material itself does not leach any substances into the product stream.

Certified Non-Toxic and Food-Grade

As a material, PTFE is inherently non-toxic and biologically safe. Regulatory bodies like the FDA have certified it for direct contact with food and drugs.

This certification provides the necessary assurance that the gasket complies with health and safety standards required in food processing and pharmaceutical manufacturing.

Superior High-Temperature Resistance

Many FDA-regulated processes involve high temperatures for sterilization, pasteurization, or other processing steps. PTFE maintains its structural integrity and superior sealing performance under these extreme thermal conditions.

Its resistance to heat ensures a reliable seal and prevents material breakdown that could otherwise lead to contamination.

Why the "Envelope" Design Matters

Understanding the term "envelope" is key to appreciating why these gaskets are so effective. This is not a solid PTFE gasket; it is a composite design engineered for optimal performance.

The Best of Both Worlds

An envelope gasket consists of a core material (the insert) wrapped in a thin layer, or "envelope," of PTFE. This design cleverly leverages the strengths of two different materials.

The PTFE envelope provides the chemically resistant, non-stick, and FDA-compliant contact surface. The core, often made from a more compressible material like rubber or a non-asbestos fiber, provides the mechanical strength, flexibility, and resilience needed for a tight seal.

Preventing Product Contamination

In this design, only the pure, inert PTFE surface ever touches the process media. This creates a perfect barrier that protects both the product from the core material and the core material from aggressive process fluids.

Enhancing Seal Reliability

The core insert provides the "rebound" and compressibility that a solid PTFE gasket might lack. This ensures the gasket can adapt to flange imperfections and maintain a consistent, leak-free seal under pressure and temperature fluctuations.

Understanding the Trade-offs

While highly effective, it's important to recognize the engineering decisions behind the envelope design and what they aim to solve.

The Challenge of Creep Relaxation

Solid PTFE, for all its benefits, has a tendency to "creep" or slowly deform over time when under a constant compressive load, especially at elevated temperatures. This can eventually lead to a loss of sealing pressure and potential leaks.

How the Envelope Design Mitigates Risk

The envelope gasket's design directly addresses this weakness. The robust core material provides the mechanical stability and resistance to creep, ensuring the seal remains tight and reliable over its service life.

Proper Core Selection is Critical

The overall performance of the gasket is highly dependent on choosing the right core material for the application's specific temperature, pressure, and chemical environment. An incorrect core can compromise the integrity of the entire seal, even with a perfect PTFE envelope.

Making the Right Choice for Your Application

Selecting the right gasket requires matching the design to your most critical operational need.

- If your primary focus is absolute product purity and chemical compatibility: The PTFE contact surface is the essential, non-negotiable feature for meeting FDA requirements.

- If your primary focus is a durable, long-lasting seal under mechanical stress: The envelope design is superior to solid PTFE, as it provides the mechanical resilience needed to prevent leaks in demanding industrial systems.

Ultimately, the PTFE envelope gasket offers a proven and compliant sealing solution by isolating sensitive products with a pure, inert surface while delivering the robust mechanical performance required for modern processing.

Summary Table:

| Key Feature | Benefit for FDA Applications |

|---|---|

| Chemical Inertness | Prevents contamination from process media or cleaning agents |

| FDA-Certified PTFE | Non-toxic, food-grade surface ensures product safety |

| High-Temperature Resistance | Maintains seal integrity during sterilization and pasteurization |

| Envelope Design | Combines PTFE purity with resilient core for reliable sealing |

Need FDA-compliant sealing solutions? KINTEK specializes in precision PTFE components, including custom envelope gaskets for the semiconductor, medical, and laboratory industries. From prototypes to high-volume orders, we ensure your gaskets meet strict purity and performance standards. Contact us today to discuss your application requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why are PTFE coated fasteners suitable for high-temperature environments? Superior Performance from -260°C to 300°C

- What makes Teflon sheets resistant to chemicals? The Power of a Molecular Fortress

- What factors are important when selecting PTFE O-ring seals? Ensure Long-Term Reliability in Harsh Environments

- What are PTFE lined pipes and where are they used? A Complete Guide to Corrosion-Resistant Piping

- What is the recommended method for bonding PTFE to its support? Achieve a Permanent, High-Strength Bond

- What are the key properties of PTFE that make it useful in sports equipment? Boost Speed and Durability

- What are the unique properties of expanded PTFE? Unlock Superior Sealing and Filtration Performance

- How do PTFE oil seals and conventional oil seals differ in terms of lubrication requirements? Unlock Superior Performance