The fundamental difference is that Polytetrafluoroethylene (PTFE) oil seals are inherently low-friction and can maintain a seal with minimal or even no lubrication. Conventional rubber oil seals, however, are entirely dependent on a consistent oil film between the sealing lip and the shaft; without it, they quickly generate heat, wear out, and fail.

The choice between a PTFE and a conventional seal is a choice between two distinct sealing philosophies. PTFE relies on its material properties to create a low-friction barrier, while a conventional seal relies on system lubrication to create a hydrodynamic one. This distinction has profound implications for reliability, efficiency, and application suitability.

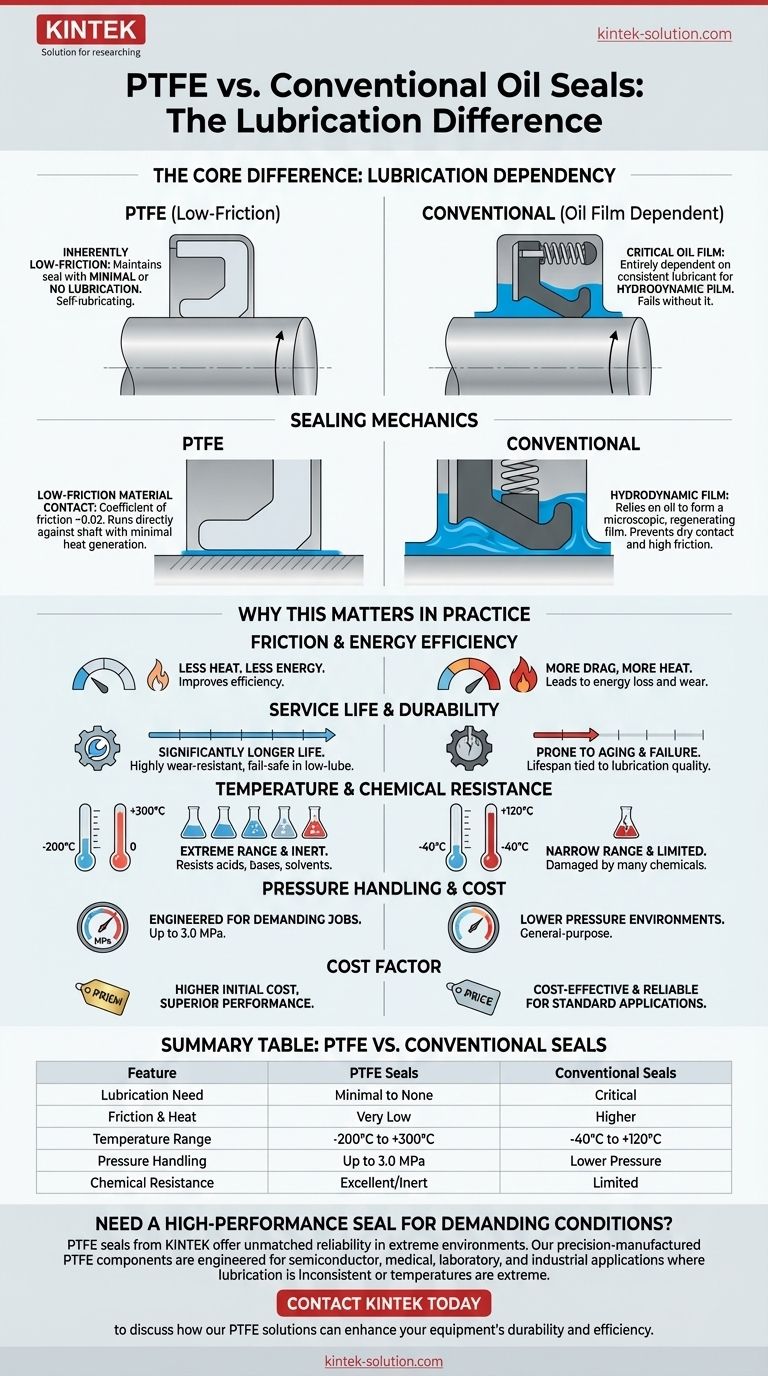

The Core Difference in Sealing Mechanics

The lubrication requirement stems from how each type of seal is designed to function at the point of contact with a rotating shaft.

How Conventional Seals Work: The Hydrodynamic Film

A conventional rubber seal is designed not to make dry contact with the shaft. Instead, it relies on the lubricant in the system to form a microscopic, constantly regenerating film of oil.

This hydrodynamic film serves as the true sealing interface. It lubricates the contact point, cools the seal lip, and prevents the high friction that would otherwise destroy the rubber material.

If this oil film is insufficient due to low lubricant levels, high temperatures, or slow shaft speeds, the seal will fail.

How PTFE Seals Work: Low-Friction Material Contact

PTFE is a material with an exceptionally low coefficient of friction (around 0.02). It is often referred to as being "self-lubricating."

This property allows the PTFE seal lip to run directly against the shaft with minimal friction and heat generation, even in dry or poorly lubricated conditions.

The seal does not depend on a fluid film to prevent wear, giving it a much wider operating window and inherent fail-safety in low-lubrication scenarios.

Why This Difference Matters in Practice

The distinction in lubrication needs directly influences seal performance across several critical metrics.

Friction and Energy Efficiency

PTFE's low friction generates significantly less heat and requires less energy to turn the shaft. This reduces operating costs and improves overall equipment efficiency.

Conventional seals create more drag, leading to energy loss and heat buildup that can degrade both the lubricant and the seal material itself over time.

Service Life and Durability

Because PTFE is highly wear-resistant and less dependent on ideal operating conditions, its service life is significantly longer. It excels in high-frequency and high-pressure applications where conventional seals wear out quickly.

Conventional seals are prone to aging, hardening, and cracking, especially in harsh environments. Their lifespan is directly tied to the quality and consistency of lubrication.

Understanding the Trade-offs

While PTFE offers superior performance in many areas, the choice is not always straightforward. It involves balancing performance requirements with environmental conditions and cost.

Temperature and Chemical Resistance

PTFE has outstanding thermal stability, operating effectively in extreme temperatures from -200°C to +300°C. It is also nearly chemically inert, resisting erosion from strong acids, bases, and solvents.

Conventional rubber seals have a much narrower operating temperature range (typically -40°C to +120°C) and can be damaged or dissolved by certain chemicals.

Pressure Handling

PTFE seals are engineered for more demanding jobs and can handle pressures up to 1.0 MPa for a single-lip design and 3.0 MPa for a double-lip design.

Conventional seals are generally intended for lower-pressure environments and are well-suited for many general-purpose mechanical sealing needs.

The Cost Factor

The superior performance of PTFE comes at a higher initial cost. Conventional seals remain a highly cost-effective and reliable solution for countless standard applications where the environment is controlled and lubrication is consistent.

Making the Right Choice for Your Application

Selecting the correct seal requires evaluating the specific demands of your system against the capabilities and costs of each type.

- If your primary focus is extreme environments: PTFE is the definitive choice for applications involving high temperatures, aggressive chemicals, or high pressures.

- If your primary focus is reliability and long service life: PTFE's wear resistance and ability to tolerate poor lubrication make it ideal for critical or low-maintenance equipment.

- If your primary focus is a cost-effective solution for standard conditions: A conventional rubber seal is an excellent and proven choice for general-purpose applications with consistent lubrication.

Ultimately, understanding the fundamental difference in their reliance on lubrication empowers you to select the seal that will deliver the most reliable performance for your specific needs.

Summary Table:

| Feature | PTFE Seals | Conventional Seals |

|---|---|---|

| Lubrication Need | Minimal to None | Critical (Requires oil film) |

| Friction & Heat | Very Low | Higher |

| Temperature Range | -200°C to +300°C | -40°C to +120°C |

| Pressure Handling | Up to 3.0 MPa | Lower Pressure |

| Chemical Resistance | Excellent (Inert) | Limited |

Need a high-performance seal for demanding conditions?

PTFE seals from KINTEK offer unmatched reliability in extreme environments. Our precision-manufactured PTFE components—including seals, liners, and labware—are engineered for semiconductor, medical, laboratory, and industrial applications where lubrication is inconsistent or temperatures are extreme.

We provide custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your unique requirements.

Contact KINTEK today to discuss how our PTFE solutions can enhance your equipment's durability and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments