For a successful and durable bond, the recommended method is to use a two-part epoxy adhesive to attach a chemically etched PTFE sheet to a meticulously prepared support surface. This approach is favored because the epoxy's shear strength is higher than that of the PTFE itself, ensuring the bond is not the weakest point in the assembly.

The key to bonding Polytetrafluoroethylene (PTFE) is not the adhesive itself, but the systematic preparation of both surfaces. A successful bond is impossible without first chemically etching the non-stick PTFE surface and mechanically preparing the support material.

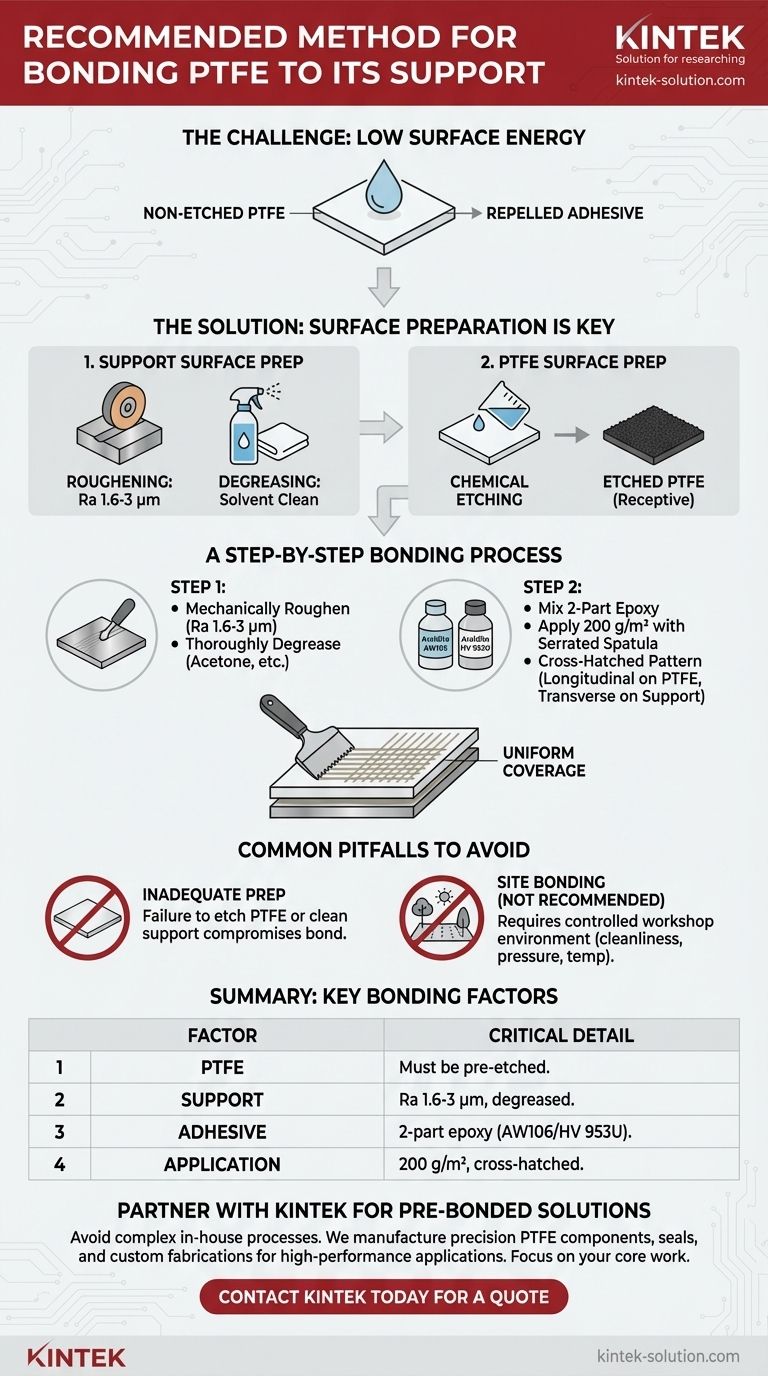

The Challenge of Bonding PTFE

PTFE, widely known by the brand name Teflon, is famously non-stick. This property, which makes it excellent for low-friction applications, also makes it incredibly difficult to glue.

The Problem of Low Surface Energy

PTFE has extremely low surface energy. This means liquids, including adhesives, bead up and are repelled from its surface rather than wetting it out and forming a strong mechanical or chemical bond.

The Solution: Chemical Etching

To overcome this, the PTFE surface must be chemically altered. This process, known as etching, uses a chemical agent to strip fluorine atoms from the polymer backbone, creating a rougher, carbonaceous surface that is receptive to adhesives. For this reason, you should always use PTFE sheets that are pre-etched on one side.

A Step-by-Step Bonding Process

Achieving a reliable bond is a matter of following a precise preparation and application procedure. Each step is critical to the final outcome.

Step 1: Prepare the Support Surface

The metal or other support material must be prepared to create an optimal anchor for the adhesive.

First, the surface must be mechanically roughened by grinding, milling, or shaping. The ideal surface roughness is between Ra = 1.6 µm and Ra = 3 µm. It should not exceed Ra = 6 µm.

After roughening, the surface must be thoroughly degreased. Clean it with a solvent like acetone, trichloroethylene, or perchloroethylene to remove all grit, oil, and debris.

Step 2: Select and Apply the Adhesive

A specific two-part epoxy is required. The recommended combination is Araldite AW106 adhesive with Araldite HV 953U hardener.

Apply the mixed adhesive uniformly to both the etched PTFE surface and the prepared support surface using a serrated spatula. The total quantity should be approximately 200 grams per square meter.

For the best dispersion, brush the adhesive longitudinally on the PTFE and transversely on the metal support. This cross-hatched pattern ensures complete coverage and minimizes air pockets.

Common Pitfalls to Avoid

The strict requirements of this process mean that certain shortcuts or environmental factors will lead to bond failure. Understanding these limitations is essential.

The Risk of Inadequate Preparation

Any failure to properly prepare the surfaces will compromise the bond. If the PTFE is not etched, the adhesive will not adhere. If the support surface is not clean and properly roughened, the adhesive will peel away.

Why Site Bonding Is Not Recommended

Attempting to bond PTFE in the field ("site bonding") is strongly discouraged. This process requires strictly controlled conditions of cleanliness, pressure, and temperature that are nearly impossible to achieve outside of a dedicated workshop environment.

Making the Right Choice for Your Goal

To ensure a permanent, high-strength bond, your focus must be on methodical preparation rather than the final act of joining the parts.

- If your primary focus is maximum durability: Follow the surface preparation protocol precisely; the mechanical roughness of the support and the cleanliness of both surfaces are the foundation of the bond's strength.

- If your primary focus is process reliability: Always purchase PTFE sheets that are already etched on one side to eliminate a complex and hazardous chemical step from your workflow.

- If you are working in a field environment: Do not attempt this procedure on-site. The required environmental controls demand a workshop setting to prevent contamination and ensure a successful outcome.

Ultimately, a successful PTFE bond is a direct result of meticulous preparation and adherence to a proven technical process.

Summary Table:

| Key Step | Critical Detail |

|---|---|

| PTFE Preparation | Must use a pre-etched PTFE sheet. |

| Support Preparation | Surface roughness (Ra) of 1.6-3 µm; degrease with solvent. |

| Adhesive | Two-part epoxy (Araldite AW106/HV 953U). |

| Application | Apply 200 g/m² in a cross-hatched pattern. |

| Environment | Requires a controlled workshop setting; site bonding is not recommended. |

Need a Reliable PTFE Component Solution?

Bonding PTFE is a complex, precision-driven process. Instead of managing this in-house, partner with KINTEK for ready-to-use, high-performance PTFE components.

We specialize in manufacturing precision PTFE seals, liners, labware, and custom fabrications for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components meet the highest standards for durability and performance, saving you time and reducing risk.

Let us handle the precision manufacturing so you can focus on your application.

Contact KINTEK today for a quote or to discuss your custom PTFE needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments