In short, PTFE and PEEK are suitable for backup rings because they possess a critical combination of high compressive strength, chemical inertness, and thermal stability. These properties allow them to act as a strong, non-reactive support for a primary seal, physically blocking it from being damaged or squeezed out of its groove under high pressure and temperature.

The core decision between PTFE and PEEK is not about which is universally better, but which is optimized for your specific operational demands. PEEK is the choice for extreme pressure and mechanical strength, while PTFE offers unparalleled chemical resistance and low-friction performance across a vast temperature range.

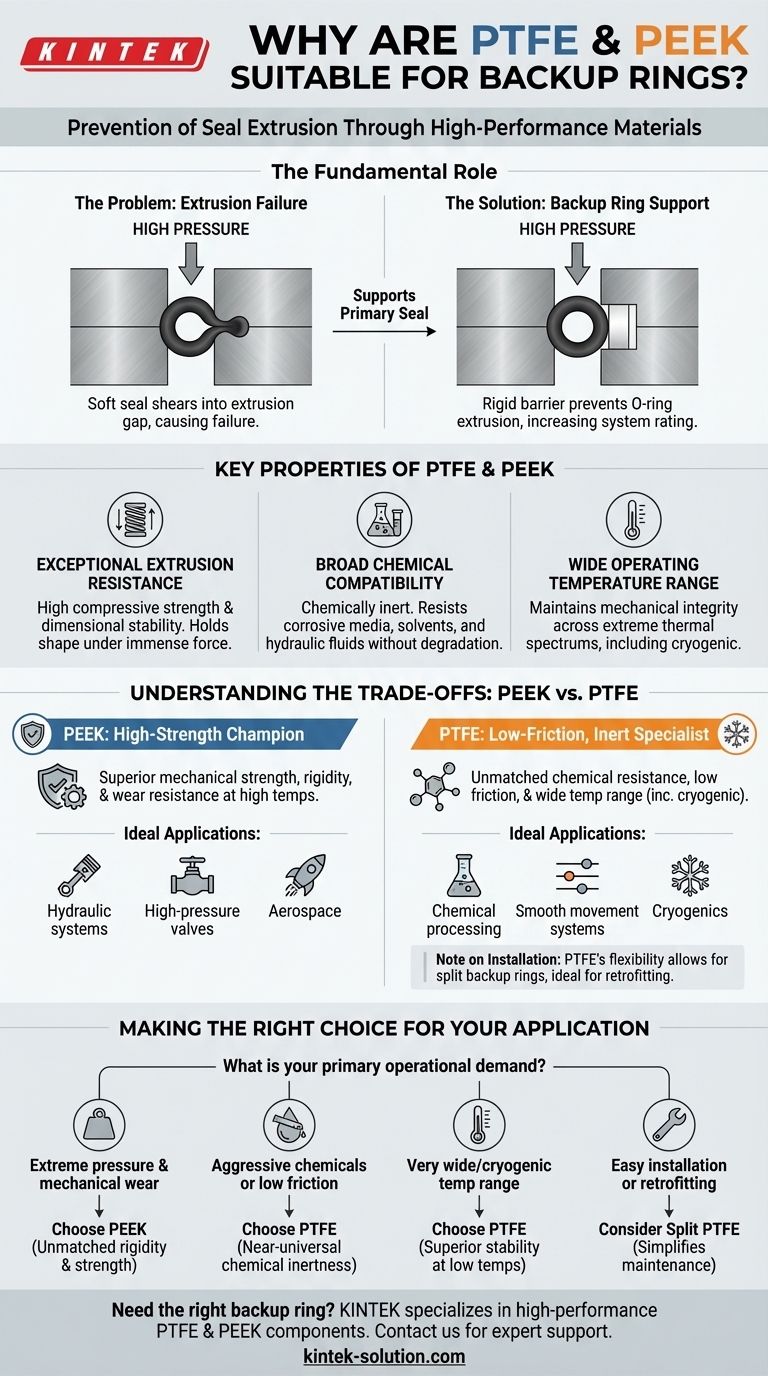

The Fundamental Role of a Backup Ring

To understand why these materials excel, we must first clarify the problem they solve: seal extrusion.

What is Extrusion Failure?

In any high-pressure sealing application, there is a small gap between the moving and stationary parts, known as the extrusion gap.

Under high pressure, a softer sealing material like a rubber O-ring can be forced into this gap. This process, called extrusion, shears off parts of the O-ring, leading to rapid seal failure and leaks.

How a Backup Ring Provides Support

A backup ring is a rigid, precisely-sized ring installed next to the O-ring. Its purpose is to close off the extrusion gap.

By providing a strong, unyielding barrier, the backup ring supports the O-ring and prevents it from being pushed into the gap, dramatically increasing the pressure and temperature rating of the entire sealing system.

Key Properties of PTFE and PEEK for Sealing

Both PTFE and PEEK share the core characteristics necessary for a high-performance backup ring, making them the two most common choices for demanding environments.

Exceptional Extrusion Resistance

The primary job of a backup ring is to resist being deformed by pressure. Both PTFE (polytetrafluoroethylene) and PEEK (polyether ether ketone) have excellent compressive strength and dimensional stability.

This means they hold their shape under immense force without extruding themselves, effectively protecting the main seal.

Broad Chemical Compatibility

Seals often operate in chemically aggressive environments, from hydraulic fluids to industrial solvents.

PTFE and PEEK are highly resistant to a wide range of chemicals. This chemical inertness ensures the backup ring will not degrade, swell, or fail when exposed to corrosive media.

Wide Operating Temperature Range

High-performance applications frequently involve extreme temperatures. Both materials maintain their mechanical integrity across a broad thermal spectrum.

PTFE is particularly notable for its performance in both high and extremely low (cryogenic) temperatures.

Understanding the Trade-offs: PTFE vs. PEEK

While they share core benefits, their distinct properties make them suitable for different application profiles. Choosing the right one is critical for reliability.

PEEK: The High-Strength Champion

PEEK is defined by its superior mechanical strength, rigidity, and wear resistance, especially at high temperatures.

This makes it the ideal choice for applications involving extreme pressures and high-intensity, long-term use, such as in hydraulic systems, high-pressure valves, and the aerospace industry.

PTFE: The Low-Friction, Chemically Inert Specialist

PTFE is known for its almost universal chemical resistance and an extremely low coefficient of friction. It resists nearly all chemicals, even in corrosive, high-temperature environments.

Its wide functional temperature range (from -200°C to 260°C) and non-stick properties make it perfect for chemical processing, applications requiring smooth movement, and cryogenic systems.

A Note on Installation

PTFE's relative flexibility allows for variations like split backup rings. These can be easily installed on a shaft without full system disassembly, making them ideal for retrofitting existing equipment or simplifying maintenance.

Making the Right Choice for Your Application

Selecting the correct material requires matching its strengths to the primary challenge of your sealing environment.

- If your primary focus is extreme pressure and mechanical wear: Choose PEEK for its unmatched rigidity and strength, which provide the best extrusion resistance in high-load systems.

- If your primary focus is aggressive chemicals or low friction: Choose PTFE for its near-universal chemical inertness and exceptionally smooth surface.

- If your primary focus is a very wide temperature range (especially cryogenic): PTFE is the superior choice due to its stability at extremely low temperatures.

- If your primary focus is easy installation or retrofitting: Consider split PTFE backup rings to simplify maintenance and reduce downtime.

By correctly identifying your most critical operational demand, you can select the material that ensures long-term integrity and reliability for your sealing system.

Summary Table:

| Material | Key Strengths | Ideal Applications |

|---|---|---|

| PEEK | Superior mechanical strength, rigidity, and wear resistance at high temperatures | Hydraulic systems, high-pressure valves, aerospace |

| PTFE | Unmatched chemical resistance, low friction, and a wide temperature range (including cryogenic) | Chemical processing, systems requiring smooth movement, cryogenics |

Need the right backup ring for your sealing system?

At KINTEK, we specialize in manufacturing high-performance PTFE and PEEK components, including custom backup rings, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your seals are protected from extrusion failure, even under extreme pressure, temperature, and chemical exposure.

Whether you require prototypes or high-volume orders, we deliver solutions tailored to your specific operational demands.

Contact us today to discuss your application and receive expert support.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications