At first glance, the high price of ePTFE gaskets can be a significant hurdle. This cost is not arbitrary; it stems directly from the complex, energy-intensive manufacturing process that transforms standard PTFE into a high-performance sealing material. This multi-stage process creates a unique microstructure that provides sealing capabilities far beyond those of less expensive alternatives.

You are not just paying for a material; you are paying for an engineered process that delivers superior reliability. The higher cost of ePTFE is a direct investment in safety and long-term performance, especially in demanding applications where other materials would fail.

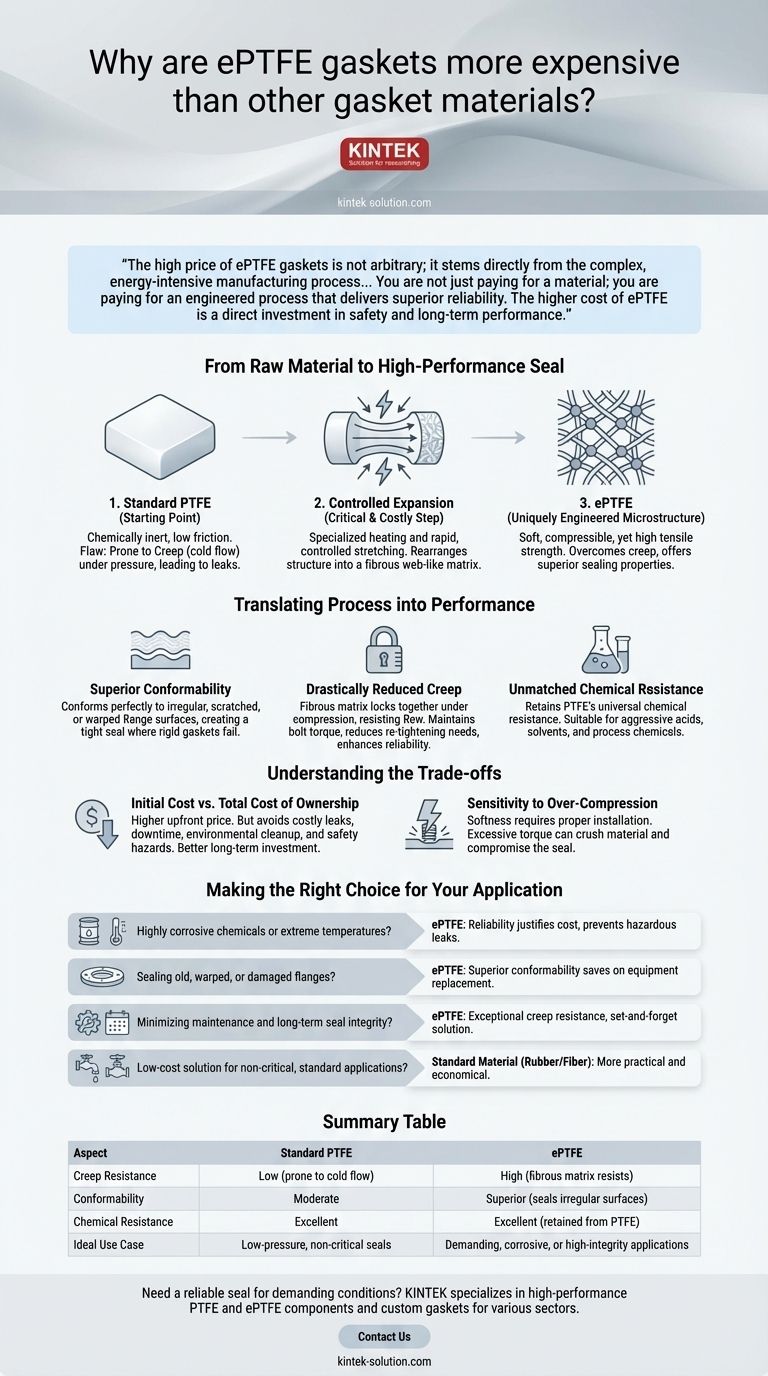

From Raw Material to High-Performance Seal

The journey from a basic polymer to an ePTFE gasket is one of precise material science. The expense is rooted in creating a structure that solves the inherent weaknesses of its parent material.

The Starting Point: Standard PTFE

Polytetrafluoroethylene (PTFE), widely known by the brand name Teflon, is the base material. It is famous for its exceptional chemical inertness and low-friction surface.

However, when used as a solid gasket, standard PTFE suffers from a critical flaw: creep, or "cold flow." Under pressure, the material slowly flows or squeezes out of the seal, leading to a loss of bolt load and eventual leakage.

The Critical Step: Controlled Expansion

To create ePTFE (expanded Polytetrafluoroethylene), solid PTFE is subjected to a specialized process of heating and rapid, controlled stretching. This expansion is the most crucial and costly step.

This process rearranges the polymer's internal structure, creating a web-like matrix of fibers and nodes. It is no longer a solid block but a porous, fibrous material.

The Result: A Uniquely Engineered Microstructure

The resulting microporous structure is what gives ePTFE its remarkable sealing properties. It is soft and highly compressible, yet the interwoven fibers provide immense tensile strength.

This structure is the key to overcoming the creep problem that plagues standard PTFE.

Translating Process into Performance

The complex manufacturing of ePTFE directly translates into tangible performance advantages that justify its cost in critical applications.

Superior Conformability

The soft, fibrous structure allows ePTFE to conform perfectly to irregular, scratched, or even slightly warped flange surfaces. It fills imperfections to create a tight seal where a harder, rigid gasket would fail.

Drastically Reduced Creep

When compressed, the fibrous ePTFE matrix locks together. This structure resists the tendency to flow away from the clamping force over time.

This means the seal remains tight, bolt torque is maintained, and the need for frequent re-tightening is significantly reduced, enhancing long-term reliability and safety.

Unmatched Chemical Resistance

The expansion process does not alter the base material's chemistry. Therefore, ePTFE retains PTFE's nearly universal chemical resistance, making it suitable for the most aggressive acids, solvents, and process chemicals.

Understanding the Trade-offs

While ePTFE is a superior material, its cost and properties make it a specific tool for specific jobs. It is not always the right choice.

The Obvious Factor: Initial Cost

The primary trade-off is the upfront purchase price. For non-critical, low-pressure applications like standard water or air lines, a less expensive rubber or fiber gasket is often a more economical and perfectly adequate solution.

Sensitivity to Over-Compression

The softness that makes ePTFE so conformable also makes it susceptible to damage from excessive bolt torque. Proper installation procedures are critical to avoid crushing the material and compromising the seal.

Total Cost of Ownership vs. Price

Focusing only on the initial price overlooks the total cost of ownership. The cost of a single leak—in terms of downtime, lost product, environmental cleanup, and safety hazards—can easily dwarf the initial savings of choosing a cheaper gasket.

Making the Right Choice for Your Application

Selecting the right gasket requires matching the material's capabilities to the application's demands.

- If your primary focus is managing highly corrosive chemicals or extreme temperatures: ePTFE's reliability justifies its cost by preventing hazardous leaks and costly downtime.

- If your primary focus is sealing old, warped, or damaged flanges: The superior conformability of ePTFE can create a reliable seal where rigid gaskets would fail, saving you from expensive equipment replacement.

- If your primary focus is minimizing maintenance and ensuring long-term seal integrity: ePTFE's exceptional creep resistance means a more stable, "set-and-forget" joint that requires less attention.

- If your primary focus is a low-cost solution for non-critical, standard applications: A less expensive material like a compressed non-asbestos or rubber gasket is likely the more practical and economical choice.

By understanding the link between its manufacturing and performance, you can confidently invest in ePTFE where its value is truly needed.

Summary Table:

| Aspect | Standard PTFE | ePTFE |

|---|---|---|

| Creep Resistance | Low (prone to cold flow) | High (fibrous matrix resists deformation) |

| Conformability | Moderate | Superior (seals irregular surfaces) |

| Chemical Resistance | Excellent | Excellent (retained from PTFE) |

| Ideal Use Case | Low-pressure, non-critical seals | Demanding, corrosive, or high-integrity applications |

Need a reliable seal for demanding conditions? KINTEK specializes in manufacturing high-performance PTFE and ePTFE components—including custom gaskets—for the semiconductor, medical, laboratory, and industrial sectors. Our precision engineering ensures your seals withstand aggressive chemicals, extreme temperatures, and high-pressure environments. Contact us today to discuss your specific sealing challenges and benefit from our expertise in custom fabrication, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why are PTFE expansion bellows considered a cost-effective long-term investment? Reduce Total Cost of Ownership

- How does PTFE's chemical resistance benefit its use in liners? Ensure Total Containment and Purity

- Why is it important to specify reinforcement requirements when selecting PTFE materials? Ensure Component Performance & Reliability

- What types of components are typically made from Teflon machined parts? Essential Parts for Extreme Conditions

- What tools and coolants are recommended for machining Teflon (PTFE)? Achieve Clean, Precise Cuts

- What are the advantages of PTFE gaskets? Superior Sealing for Extreme Chemical & Thermal Environments

- What are the chemical resistance properties of PTFE? Unmatched Inertness for Demanding Applications

- Why choose PTFE V-Ring seals? Unmatched Reliability for Extreme Conditions