At its core, Teflon (PTFE) is specified for machined parts that must operate in extreme conditions. The most common components are seals, gaskets, bushings, bearings, valve seats, and electrical insulators. These parts are chosen specifically for applications where exceptional chemical resistance, a very low-friction surface, or high-temperature stability is a non-negotiable requirement.

The decision to machine a part from Teflon is almost never about structural strength. It's a strategic choice for components that must provide a reliable seal, a low-friction surface, or electrical insulation in environments that are too chemically aggressive or temperature-variable for other polymers.

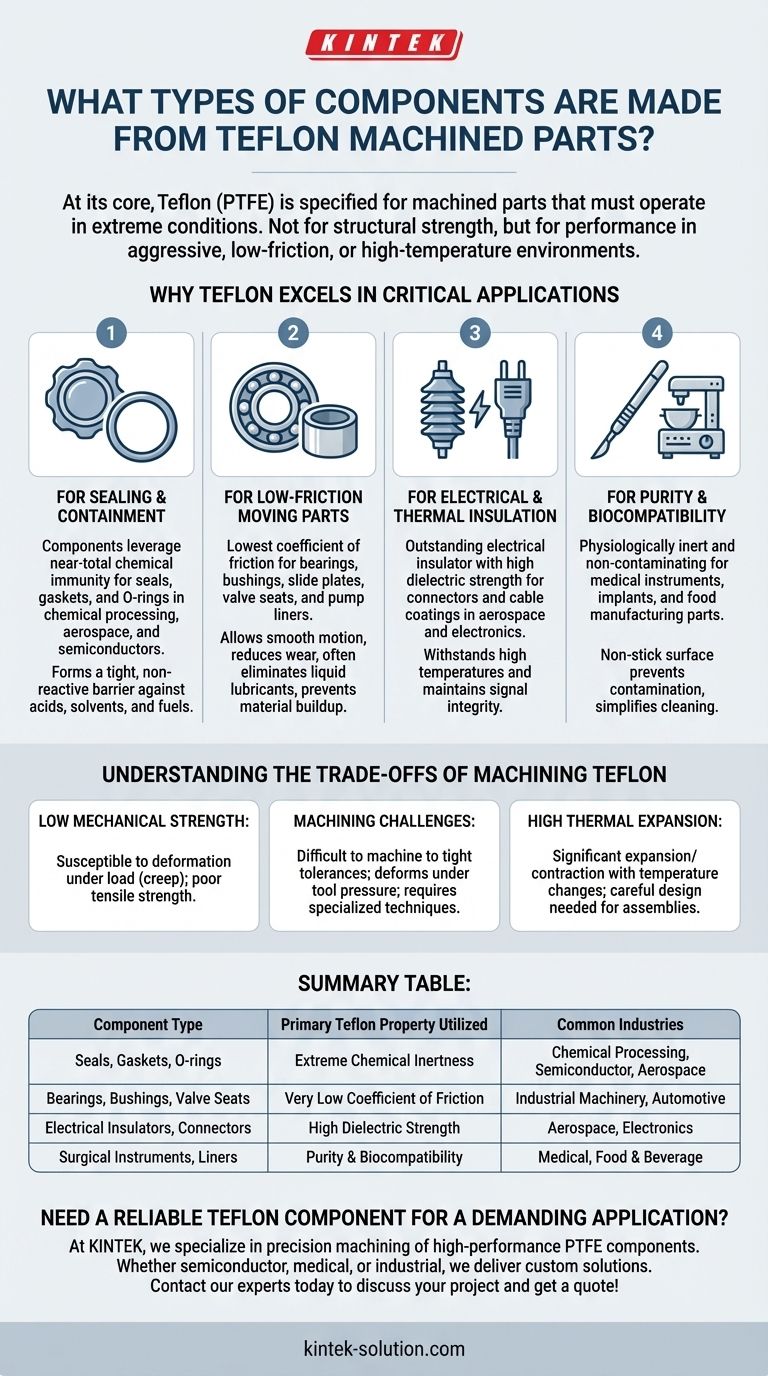

Why Teflon Excels in Critical Applications

The types of components made from Teflon are directly linked to its three primary material properties: extreme chemical inertness, a very low coefficient of friction, and excellent dielectric strength. We can group the most common parts by the problems they are designed to solve.

For Sealing and Containment

Components in this category leverage Teflon's near-total immunity to chemical attack.

This makes it the material of choice for seals, gaskets, and O-rings used in the chemical processing, aerospace, and semiconductor industries. These parts form a tight, non-reactive barrier that won't degrade when exposed to aggressive acids, solvents, or fuels.

For Low-Friction Moving Parts

Teflon has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice.

This property makes it ideal for bearings, bushings, and slide plates. These components allow parts to move against each other with minimal resistance and wear, often eliminating the need for liquid lubricants entirely.

You will also find it used for valve seats and pump liners, where its low-friction, non-stick surface prevents material buildup and ensures smooth, reliable operation over time.

For Electrical and Thermal Insulation

Teflon is an outstanding electrical insulator with a high dielectric strength and excellent performance at high frequencies.

This leads to its widespread use as electrical insulators, connectors, and cable coatings, particularly in the aerospace and electronics industries. Its ability to withstand high temperatures ensures signal integrity and component safety in demanding environments.

For Purity and Biocompatibility

Because Teflon is physiologically inert and non-contaminating, it is highly valued in sensitive applications.

In the medical industry, it's used for surgical instruments, implants, and fluid-handling components. In food manufacturing, it is used for machinery parts that come into direct contact with food products, as its non-stick surface prevents contamination and simplifies cleaning.

Understanding the Trade-offs of Machining Teflon

While its properties are unique, Teflon is not a universal solution. Understanding its limitations is critical for proper application.

Low Mechanical Strength

Pure Teflon (PTFE) is a relatively soft material. It has poor tensile strength and is susceptible to "creep," or deformation under sustained load. It is not suitable for structural components that must bear significant mechanical stress.

Machining Challenges

The softness that makes Teflon easy to cut also makes it difficult to machine to extremely tight tolerances. The material can deform under tool pressure or clamping force, requiring specialized techniques and sharp tooling to achieve precise results.

High Thermal Expansion

Teflon expands and contracts with temperature changes more than most metals or other engineering plastics. This must be carefully considered in the design phase for any assembly that will operate across a wide temperature range to avoid part failure.

Making the Right Choice for Your Goal

Selecting Teflon is about matching its unique strengths to a specific operational challenge.

- If your primary focus is chemical immunity: Teflon is the default choice for seals, gaskets, and liners exposed to aggressive chemicals where other materials would quickly corrode.

- If your primary focus is reducing friction without lubrication: Use Teflon for bearings, bushings, and slide plates where smooth, clean, and self-lubricating motion is required.

- If your primary focus is high-frequency electrical insulation: Teflon provides outstanding performance for insulators and connectors where signal integrity is paramount, especially in aerospace or electronics.

- If your primary focus is purity or biocompatibility: It is an essential material for components in medical devices and food processing equipment that cannot tolerate any risk of contamination.

Ultimately, choosing to machine a part from Teflon is a decision to prioritize performance and reliability in environments where most other materials would fail.

Summary Table:

| Component Type | Primary Teflon Property Utilized | Common Industries |

|---|---|---|

| Seals, Gaskets, O-rings | Extreme Chemical Inertness | Chemical Processing, Semiconductor, Aerospace |

| Bearings, Bushings, Valve Seats | Very Low Coefficient of Friction | Industrial Machinery, Automotive |

| Electrical Insulators, Connectors | High Dielectric Strength | Aerospace, Electronics |

| Surgical Instruments, Liners | Purity & Biocompatibility | Medical, Food & Beverage |

Need a reliable Teflon component for a demanding application?

At KINTEK, we specialize in precision machining of high-performance PTFE components like seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we deliver custom solutions—from prototypes to high-volume orders—that meet your exact specifications for chemical resistance, low friction, and thermal stability.

Contact our experts today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments