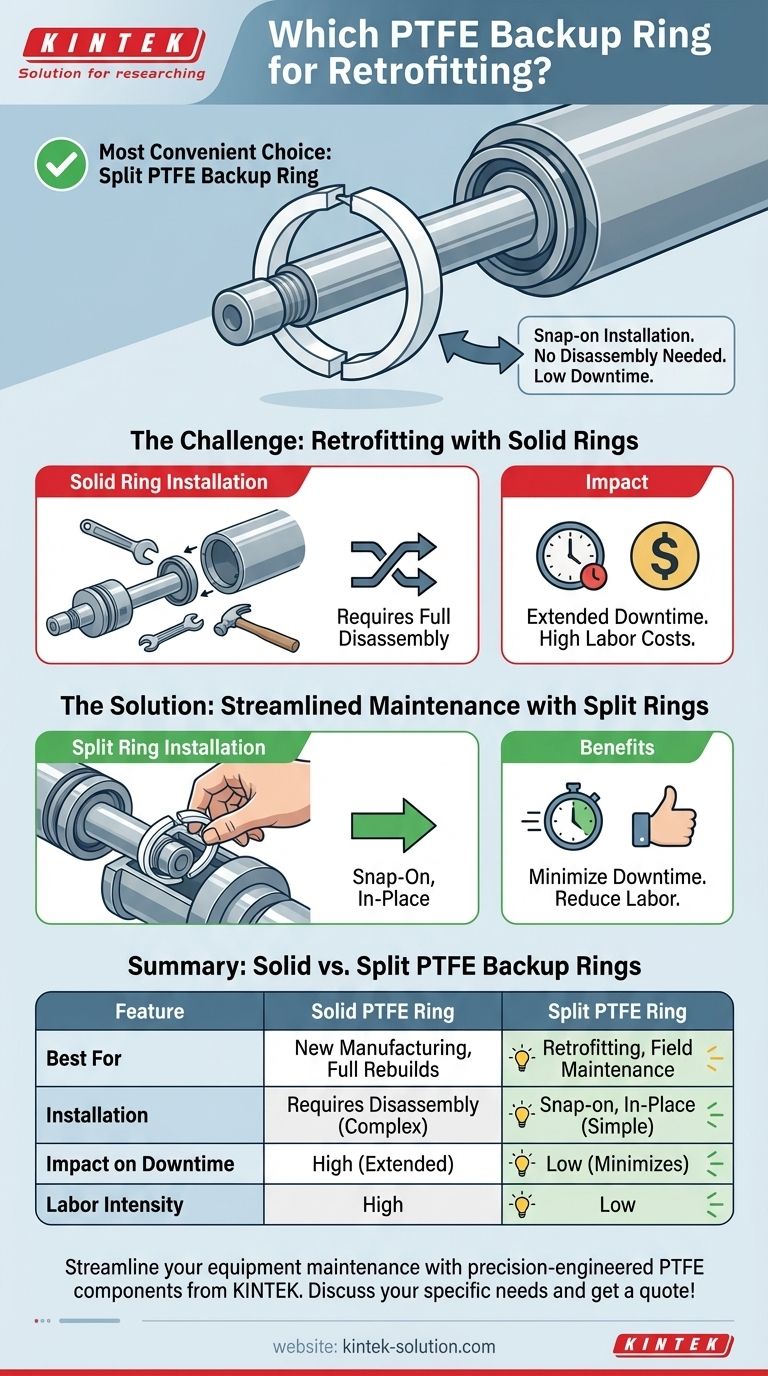

For retrofitting existing systems, the most convenient and practical choice is the split PTFE backup ring. This design features a single cut, allowing it to be stretched open and snapped directly into the groove without needing to disassemble the primary components, such as removing a piston from a cylinder.

When maintaining equipment that is already assembled, the central challenge is accessibility. Split backup rings are engineered specifically to solve this problem, enabling installation and replacement in place, which dramatically reduces labor and system downtime.

The Challenge of Retrofitting Seals in Assembled Systems

When an O-ring and its backup ring need replacement in a functioning piece of equipment, the design of the backup ring becomes a critical factor in the efficiency and cost of the repair.

The Problem with Solid Rings

Solid, or uncut, backup rings are a continuous loop of material. To install one, it must be slid over the end of the component, such as a piston rod or shaft.

This requires the complete disassembly of the component from its housing. This process is often complex, time-consuming, and labor-intensive.

The Impact on Downtime and Labor

The need for full disassembly directly translates to extended equipment downtime and higher maintenance costs. What could be a quick replacement becomes a major overhaul.

How Split Backup Rings Streamline Maintenance

The simple addition of a cut in the ring fundamentally changes the installation process and makes it ideal for retrofitting.

A "Snap-On" Installation

A split backup ring can be opened slightly at its cut. This allows a technician to stretch it over the body of a shaft and snap it directly into the seal groove.

Eliminating the Need for Disassembly

This design entirely removes the requirement to disassemble the system. The repair can be performed in-place, which is a significant advantage for equipment that is large, complex, or located in an area with limited access.

Ideal for Field Repairs

Because they simplify the maintenance process so drastically, split backup rings are the standard choice for on-site or field repairs where bringing equipment back to a workshop is impractical.

Understanding the Trade-offs

While split rings are superior for retrofitting, it's important to understand their context and performance.

Sealing Performance is Uncompromised

A common misconception is that the split creates a path for extrusion. However, when installed correctly in the gland, the backup ring is supported by the hardware. The O-ring energizes the backup ring, pressing it against the cylinder wall and effectively closing the gap from the split. Its function of preventing extrusion remains fully intact.

Installation Care

While installation is easier, it requires care. The technician must ensure the split ends do not overlap or get pinched by the O-ring, as this could compromise the seal.

When to Use Solid Rings

For new product manufacturing or during a complete system overhaul where components are already disassembled, solid rings are perfectly suitable. Their installation is straightforward in this context, and they are often slightly more economical.

Making the Right Choice for Your Goal

Selecting the correct backup ring design is essential for efficient and cost-effective sealing system management.

- If your primary focus is retrofitting or field maintenance: Choose split PTFE backup rings to minimize system downtime and labor costs by avoiding component disassembly.

- If your primary focus is new manufacturing or a full system rebuild: Solid (uncut) backup rings are a simple and effective choice, as installation takes place before the final assembly.

Ultimately, choosing the component designed for your specific maintenance reality is key to a streamlined and effective operation.

Summary Table:

| Feature | Solid PTFE Backup Ring | Split PTFE Backup Ring |

|---|---|---|

| Best For | New manufacturing, full rebuilds | Retrofitting, field maintenance |

| Installation | Requires full component disassembly | Snap-on, in-place installation |

| Impact on Downtime | High (extended disassembly time) | Low (minimizes system downtime) |

| Labor Intensity | High | Low |

Streamline your equipment maintenance with precision-engineered PTFE components from KINTEK.

Facing challenges with retrofitting seals in your semiconductor, medical, or industrial equipment? Our custom-fabricated split PTFE backup rings are designed specifically for quick, in-place installation to drastically reduce your maintenance downtime and labor costs.

We specialize in manufacturing high-performance PTFE seals, liners, and labware with a focus on precision. Whether you need prototypes or high-volume orders, we provide custom solutions tailored to your specialized requirements.

Enhance your operational efficiency – Contact our experts today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions