For extreme temperature and aggressive chemical environments, the definitive choice is a Polytetrafluoroethylene (PTFE) oil seal. Unlike traditional rubber seals that degrade under harsh conditions, PTFE seals are specifically engineered with a robust material jacket and an internal energizing spring to maintain sealing integrity across a vast operational range.

The critical insight is that PTFE seals are not just a different material, but a different design philosophy. They solve the challenges of extreme environments by combining a chemically inert, temperature-resistant PTFE jacket with a metal spring that provides the consistent mechanical force that the polymer itself lacks.

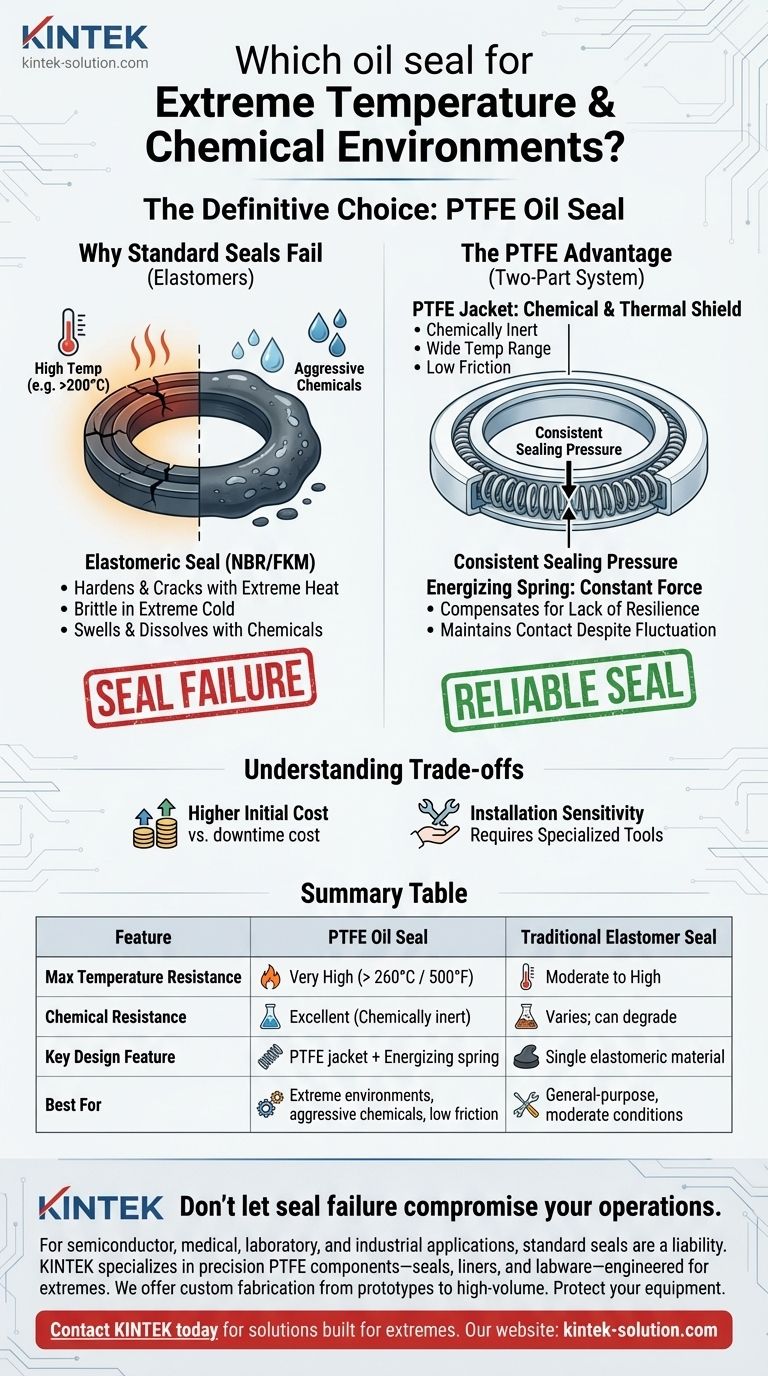

Why Standard Seals Fail in Extreme Environments

The Limits of Elastomers

Traditional oil seals are typically made from elastomeric materials like Nitrile (NBR) or Viton (FKM). While effective in standard operating conditions, these materials have inherent thermal and chemical limits.

Extreme heat can cause them to harden and crack, while extreme cold can make them brittle and lose flexibility. Aggressive chemicals can cause them to swell, soften, or dissolve, leading to catastrophic seal failure.

The PTFE Advantage: A Two-Part System

PTFE seals overcome the limitations of elastomers through a superior two-component design. This system separates the function of chemical resistance from the function of mechanical sealing force.

The PTFE Jacket: Your Chemical and Thermal Shield

The outer component, or "jacket," of the seal is made from a specialized blend of PTFE. This material provides the primary defense against hostile environments.

Its key properties are chemical inertness (it does not react with aggressive fluids), a very wide operating temperature range, and low friction, which reduces heat generation and wear in high-speed applications.

The Energizing Spring: Providing Constant Force

PTFE is a durable but relatively rigid material; it lacks the natural "bounciness" or resilience of rubber. To ensure a tight seal against a shaft, it requires a constant mechanical load.

This is the job of the internal energizing spring, typically made from a corrosion-resistant metal like stainless steel. This spring provides a consistent outward force on the PTFE jacket, compensating for the material's lack of resilience and ensuring it maintains contact with the shaft despite temperature fluctuations or minor wear.

Understanding the Trade-offs

While superior in performance for extreme applications, PTFE seals have considerations that are important to understand for proper implementation.

Higher Initial Cost

The advanced materials and multi-component construction make PTFE seals more expensive than their standard elastomeric counterparts. This cost must be weighed against the potential cost of downtime and failure in a critical application.

Installation Sensitivity

Because PTFE is more rigid than rubber, it is less forgiving during installation. Care must be taken to avoid scratching or gouging the seal lip, as any imperfection can create a leak path. Specialized installation tools are often recommended.

Making the Right Choice for Your Application

Selecting the correct seal requires evaluating your specific operational demands against the capabilities and costs of the component.

- If your primary focus is reliability in extreme temperatures or with aggressive chemicals: A PTFE oil seal is the only suitable choice for long-term, dependable performance.

- If your primary focus is high-speed rotational applications with low friction: The naturally low coefficient of friction of the PTFE jacket makes it a superior option over rubber seals.

- If your primary focus is a general-purpose application within moderate temperature and chemical ranges: A standard, high-quality elastomer seal is likely the more cost-effective solution.

Ultimately, choosing a PTFE seal is an investment in reliability where standard components are guaranteed to fail.

Summary Table:

| Feature | PTFE Oil Seal | Traditional Elastomer Seal |

|---|---|---|

| Max Temperature Resistance | Very High (e.g., > 260°C / 500°F) | Moderate to High |

| Chemical Resistance | Excellent (Chemically inert) | Varies; can degrade |

| Key Design Feature | PTFE jacket + Energizing spring | Single elastomeric material |

| Best For | Extreme environments, aggressive chemicals, low friction | General-purpose, moderate conditions |

Don't let seal failure compromise your critical operations.

For semiconductor, medical, laboratory, and industrial applications where extreme temperatures and aggressive chemicals are the norm, standard seals are a liability. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—that are engineered for these exact challenges.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get a seal that delivers unmatched reliability. Protect your equipment and ensure uptime.

Contact KINTEK today to discuss your specific requirements and get a solution built for extremes.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F