In short, PTFE cryogenic seals are predominantly used in industries that handle fluids at extremely low temperatures and high pressures, most notably Aerospace, Oil & Gas, and Pharmaceuticals. These sectors rely on PTFE's unique ability to remain functional and avoid becoming brittle in cryogenic conditions where many other materials would fail.

The decision to use a PTFE cryogenic seal is rarely about temperature alone. It is driven by the material's unique combination of thermal stability, chemical inertness, and low-friction properties, making it indispensable for applications where performance and purity are non-negotiable.

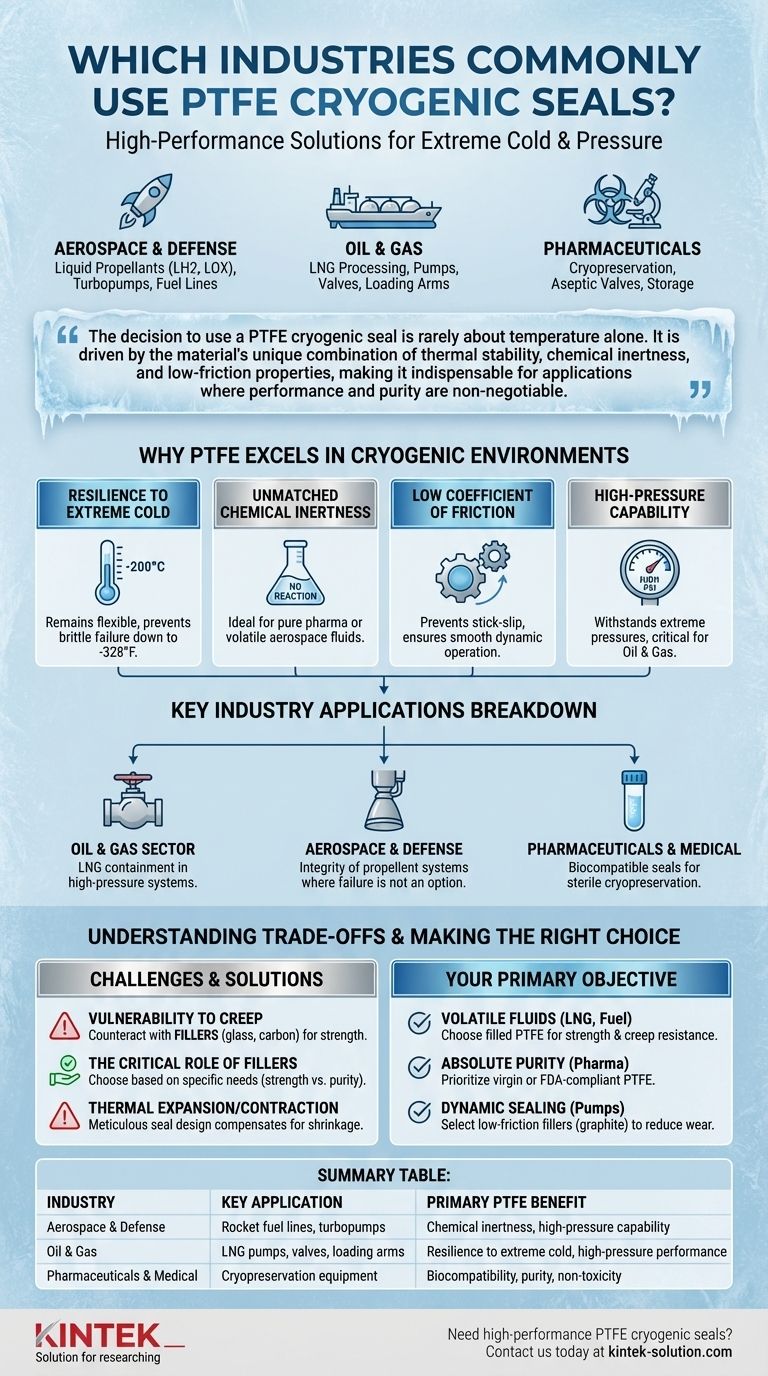

Why PTFE Excels in Cryogenic Environments

To understand where these seals are used, we must first understand the material itself. PTFE (Polytetrafluoroethylene) possesses a set of properties that make it uniquely suited for the challenges of sealing substances like liquid nitrogen or liquefied natural gas (LNG).

Resilience to Extreme Cold

Unlike many polymers that become hard and brittle at low temperatures, PTFE maintains a significant degree of flexibility and toughness even at cryogenic temperatures, down to -200°C (-328°F) and below. This prevents cracking and seal failure.

Unmatched Chemical Inertness

PTFE is virtually inert and does not react with the vast majority of chemicals. This is critical when handling highly pure substances in pharmaceutical applications or highly volatile ones like liquid oxygen (LOX) in aerospace.

Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material. For dynamic seals in pumps or valves, this prevents stick-slip and reduces wear, ensuring smooth operation even when components are super-chilled.

High-Pressure Capability

When engineered correctly, often with fillers, PTFE seals can withstand extremely high pressures. This combination of high-pressure and low-temperature performance is essential for applications in the oil and gas industry.

Key Industry Applications Breakdown

The properties of PTFE directly translate into critical applications within specific high-tech industries.

The Oil & Gas Sector

In the Oil & Gas industry, the primary application is in the processing and transport of liquefied natural gas (LNG).

PTFE cryogenic seals are critical components in pumps, valves, and loading arms used at LNG terminals, ensuring the safe and efficient containment of this high-pressure, cryogenic fluid.

Aerospace and Defense

The aerospace industry relies on cryogenic fluids as rocket propellants, such as liquid hydrogen (LH2) and liquid oxygen (LOX).

These seals are fundamental to the integrity of turbopumps, fuel lines, and valve systems within rocket engines, where failure is not an option.

Pharmaceuticals and Medical

This sector uses cryogenic temperatures for cryopreservation—the storage of biological samples like tissues, cells, and blood in liquid nitrogen.

Because PTFE is non-toxic and biocompatible, its seals are used in storage equipment, aseptic valves, and analytical tools to maintain sterile, leak-free environments.

Understanding the Trade-offs and Limitations

While powerful, PTFE is not without its engineering challenges, particularly in cryogenic applications. Understanding these is key to successful implementation.

Vulnerability to Creep

Under sustained pressure, PTFE can be susceptible to creep or "cold flow," where the material slowly deforms. This can compromise sealing integrity over time.

The Critical Role of Fillers

To counteract creep and enhance mechanical properties, pure PTFE is often blended with fillers like glass fiber, carbon, bronze, or graphite. The choice of filler is critical and depends entirely on the specific application's demands for strength, friction, and chemical compatibility.

Thermal Expansion and Contraction

PTFE has a relatively high rate of thermal expansion and contraction. Seal design must meticulously account for how the material will shrink as it cools to ensure it maintains constant pressure against its mating surfaces and doesn't leak.

Making the Right Choice for Your Goal

Selecting the appropriate PTFE seal formulation is essential for mission success. Your primary objective should guide your material choice.

- If your primary focus is handling volatile fluids (like LNG or rocket fuel): Choose a PTFE compound with fillers like glass fiber or carbon to enhance strength and minimize creep, ensuring a robust seal under high pressure.

- If your primary focus is maintaining absolute purity (like in pharmaceuticals): Prioritize virgin PTFE or seals with FDA-compliant fillers to prevent any possibility of contamination while ensuring performance at cryogenic temperatures.

- If your primary focus is dynamic sealing (in cryogenic pumps or valves): Select a PTFE blend containing graphite or other low-friction fillers to reduce wear, prevent stick-slip, and ensure reliable, smooth operation.

Ultimately, leveraging PTFE successfully in cryogenic applications comes from understanding that it is a highly engineered solution, not just a piece of plastic.

Summary Table:

| Industry | Key Application | Primary PTFE Benefit |

|---|---|---|

| Aerospace & Defense | Rocket engine fuel lines, turbopumps | Chemical inertness, high-pressure capability |

| Oil & Gas | LNG pumps, valves, loading arms | Resilience to extreme cold, high-pressure performance |

| Pharmaceuticals & Medical | Cryopreservation equipment, aseptic valves | Biocompatibility, purity, non-toxicity |

Need high-performance PTFE cryogenic seals for your demanding application? At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures reliable performance in extreme conditions. Contact us today to discuss your specific requirements and benefit from our custom fabrication solutions!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support