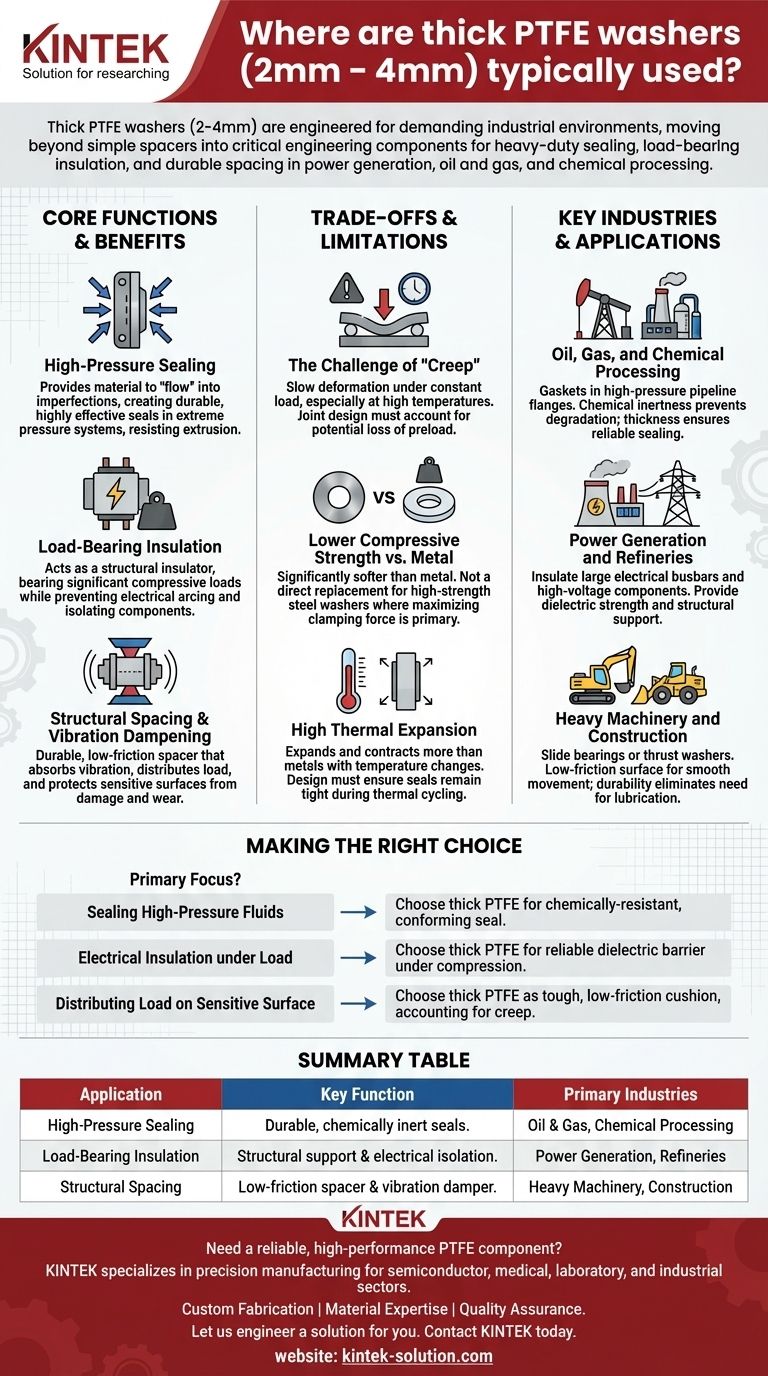

Thick PTFE washers, typically in the 2mm to 4mm range, are engineered for demanding industrial environments where standard washers would fail. They are primarily used for heavy-duty sealing in high-pressure systems, as load-bearing insulators in electrical applications, and as durable spacers in heavy machinery, particularly within the power generation, oil and gas, and chemical processing industries.

The decision to use a thick PTFE washer is driven by the need for structural resilience combined with PTFE's inherent properties. Its thickness amplifies its ability to act as a robust electrical insulator, a high-pressure seal, or a load-bearing cushion, moving it beyond a simple spacer into a critical engineering component.

The Core Functions of Thick PTFE Washers

The value of a thick PTFE washer comes from its ability to perform under significant mechanical, electrical, or chemical stress. The increased material thickness directly enhances its performance in three key areas.

High-Pressure Sealing

In applications like oil and gas pipelines or industrial processing plants, connections and flanges are subjected to extreme pressure. A thick PTFE washer provides more material to deform and "flow" into imperfections, creating a highly effective and durable seal that resists being extruded from the joint.

Load-Bearing Insulation

In power generation or heavy electrical equipment, components must be both mechanically secured and electrically isolated. A thick PTFE washer serves as a structural insulator, capable of bearing a significant compressive load without cracking while preventing electrical arcing between assemblies.

Structural Spacing and Vibration Dampening

In heavy machinery and construction equipment, these washers act as durable, low-friction spacers. Their thickness allows them to absorb vibration and distribute the load from a bolt or screw over a wider area, preventing damage to sensitive surfaces while resisting wear.

Understanding the Trade-offs and Limitations

While highly capable, thick PTFE is not a universal solution. Understanding its inherent material properties is critical to using it correctly and avoiding application failure.

The Challenge of "Creep"

PTFE is known for "creep" or "cold flow," meaning it can slowly deform over time under a constant load. This is especially true at elevated temperatures. In high-torque bolted joints, this can lead to a loss of preload, so the joint design must account for this behavior.

Lower Compressive Strength vs. Metal

While considered "load-bearing" for an insulating polymer, PTFE is significantly softer and has a lower compressive strength than any metal washer. It should not be used as a direct replacement for a high-strength steel washer in applications where the primary goal is maximizing clamping force.

High Thermal Expansion

PTFE expands and contracts with temperature changes more than metals do. In systems with significant thermal cycling, this must be considered in the design to ensure seals remain tight and clearances are maintained across the entire operating temperature range.

Key Industries and Specific Applications

The unique combination of properties makes thick PTFE washers essential components in several specific industrial contexts.

Oil, Gas, and Chemical Processing

Thick PTFE washers are commonly used as gaskets in flange connections for high-pressure pipelines. Their chemical inertness means they will not degrade when exposed to aggressive chemicals, and their thickness ensures a reliable seal.

Power Generation and Refineries

These washers are used to insulate large electrical busbars and other high-voltage components. They provide the necessary dielectric strength to prevent shorts while being strong enough to support the weight and clamping force of the assemblies.

Heavy Machinery and Construction

In large mechanical systems, thick PTFE washers can be used as slide bearings or thrust washers. Their low-friction surface allows for smooth movement between parts while their durability provides a long service life with no need for lubrication.

Making the Right Choice for Your Goal

To determine if a thick PTFE washer is the correct component, consider your primary engineering challenge.

- If your primary focus is sealing high-pressure fluids: A thick PTFE washer provides an exceptional, chemically-resistant seal capable of conforming to surface imperfections under load.

- If your primary focus is electrical insulation under a significant load: The washer's thickness creates a reliable dielectric barrier that resists being crushed, making it ideal for isolating critical electrical components.

- If your primary focus is distributing load on a sensitive surface: The washer acts as a tough, low-friction cushion, but you must ensure your design accounts for the potential of material creep over time.

Ultimately, a thick PTFE washer is a specialized component chosen when an application demands a combination of sealing, insulation, and mechanical resilience that thinner alternatives cannot provide.

Summary Table:

| Application | Key Function | Primary Industries |

|---|---|---|

| High-Pressure Sealing | Creates durable, chemically inert seals in flanges and connections. | Oil & Gas, Chemical Processing |

| Load-Bearing Insulation | Provides structural support and electrical isolation for high-voltage components. | Power Generation, Refineries |

| Structural Spacing | Acts as a durable, low-friction spacer and vibration damper in machinery. | Heavy Machinery, Construction |

Need a reliable, high-performance PTFE component for your demanding application?

KINTEK specializes in the precision manufacturing of PTFE washers and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your parts meet the exact requirements for pressure, temperature, and chemical resistance.

We provide:

- Custom Fabrication: From prototypes to high-volume production runs.

- Material Expertise: Optimal solutions for sealing, insulation, and structural applications.

- Quality Assurance: Precision production for reliable performance in critical environments.

Let us engineer a solution for you. Contact KINTEK today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications