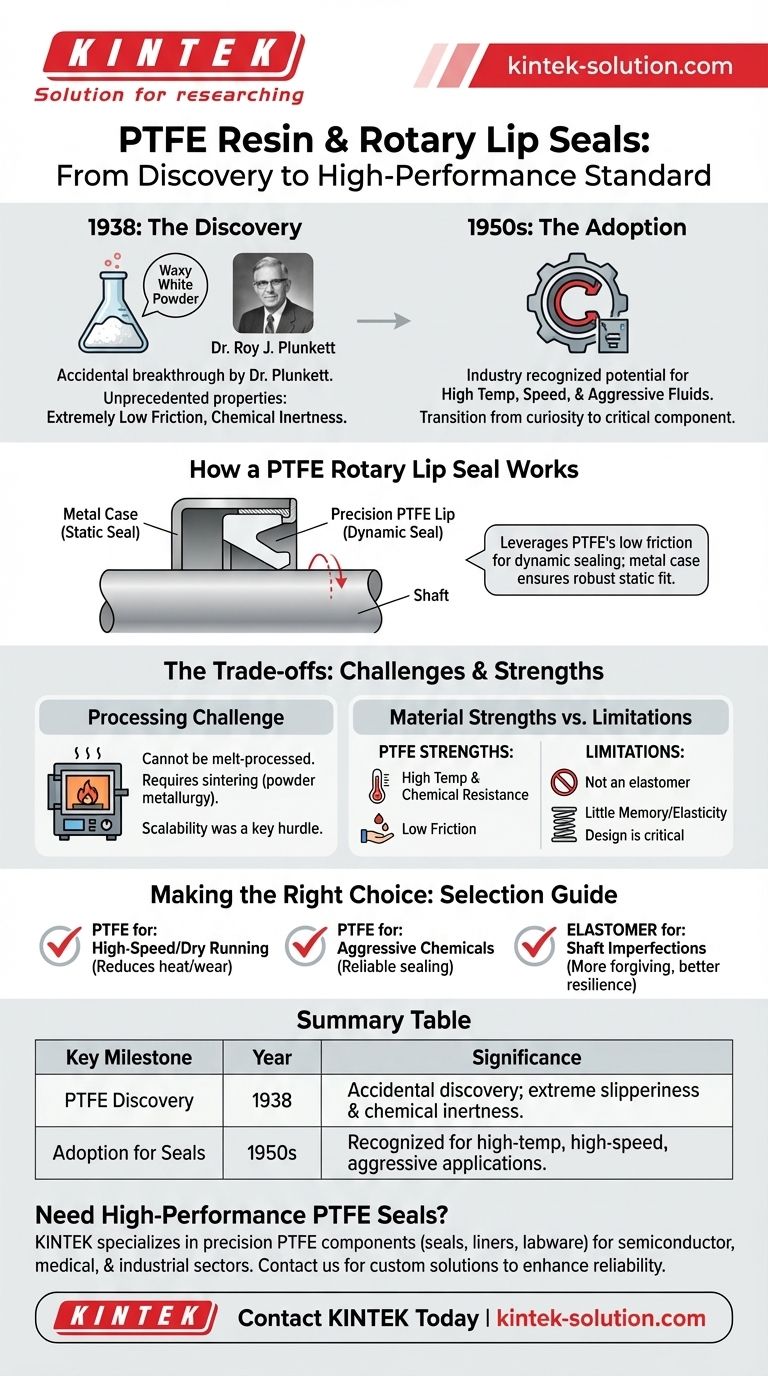

While discovered by accident, Polytetrafluoroethylene (PTFE) resin was first identified in 1938, but its potential as a high-performance material for rotary lip seals was not recognized until the 1950s. This significant time lag represents the transition from a chemical curiosity to a fundamental component in modern engineering.

The journey of PTFE from its discovery in 1938 to its adoption for seals in the 1950s was not immediate. This delay highlights the time required for industry to understand its unique properties and develop the manufacturing techniques needed to harness its potential in demanding dynamic applications.

The Discovery of a Unique Material

An Accidental Breakthrough

The discovery of PTFE occurred on April 6, 1938, by American scientist Dr. Roy J. Plunkett. He was not searching for a new polymer but rather investigating refrigerant gases when he discovered a strange, waxy white powder that was remarkably slippery and inert.

Unprecedented Properties

Early observations revealed that this new material possessed an extremely low coefficient of friction and was astonishingly resistant to chemical attack. However, it was also difficult to work with and process using conventional methods, which initially limited its practical applications.

The Leap to Sealing Technology

A Solution for Demanding Applications

By the 1950s, advancements in the automotive and industrial sectors created a need for seals that could withstand higher temperatures, faster rotational speeds, and more aggressive fluids than traditional elastomer seals could handle. Engineers began to recognize that PTFE's unique properties were an ideal match for these challenges.

The Function of a PTFE Rotary Lip Seal

A PTFE rotary lip seal is a specialized component designed for dynamic sealing in rotating equipment. It typically consists of a precision-engineered PTFE lip on its inner diameter that makes contact with the rotating shaft.

This lip is housed within a rigid metal casing on the outer diameter, which allows it to be press-fit securely into a stationary housing or bore. This design leverages PTFE's low friction for the dynamic sealing surface while relying on the metal case for a robust static seal.

Understanding the Trade-offs

The Processing Challenge

Unlike common plastics, PTFE cannot be melt-processed. It must be formed through a sintering process similar to powdered metallurgy. Developing reliable and scalable manufacturing techniques for this process was a key hurdle that contributed to the delay between its discovery and widespread adoption.

Material Strengths and Limitations

While superior in temperature and chemical resistance, PTFE is not an elastomer. It has very little "memory" or elasticity compared to rubber. This means seal design is more critical, as a PTFE lip cannot rely on the same resilience as a rubber seal to maintain contact with the shaft.

Making the Right Choice for Your Application

Understanding this history helps clarify where PTFE seals excel today. Your selection should be guided by the specific demands of your equipment.

- If your primary focus is high-speed rotation or dry running: PTFE's extremely low coefficient of friction makes it a superior choice, reducing heat generation and wear where lubrication is minimal.

- If your primary focus is aggressive chemical compatibility: PTFE's near-total chemical inertness provides a reliable sealing solution where most elastomers would quickly degrade.

- If your primary focus is dealing with shaft imperfections or misalignment: An elastomeric seal may be more forgiving due to its higher flexibility and resilience compared to the more rigid nature of PTFE.

The journey of PTFE from lab discovery to essential component underscores the importance of matching a material's unique strengths to the right engineering challenge.

Summary Table:

| Key Milestone | Year | Significance |

|---|---|---|

| PTFE Discovery | 1938 | Accidental discovery by Dr. Roy J. Plunkett; material noted for extreme slipperiness and chemical inertness. |

| Adoption for Rotary Lip Seals | 1950s | Recognition of PTFE's suitability for high-temperature, high-speed, and chemically aggressive sealing applications. |

Need High-Performance PTFE Seals for Your Application?

PTFE's journey from a lab curiosity to a critical engineering material shows the importance of matching the right material to the challenge. At KINTEK, we specialize in precision manufacturing of PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our expertise ensures you get a component that leverages PTFE's unique properties for superior performance.

Contact KINTEK today to discuss your specific requirements and discover how our custom PTFE solutions can enhance your equipment's reliability and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance