In the oil and gas industry, the most common PTFE components are high-performance seals, gaskets, expansion joints, and valve components. These parts are specifically engineered to maintain integrity in the sector's uniquely hostile environments, handling everything from downhole tools and subsea equipment to LNG pipelines.

The core reason PTFE is indispensable in oil and gas is not simply its chemical resistance, but its unique ability to provide reliable, long-lasting sealing and structural integrity under a combination of extreme pressures, wide temperature ranges, and chemically aggressive media.

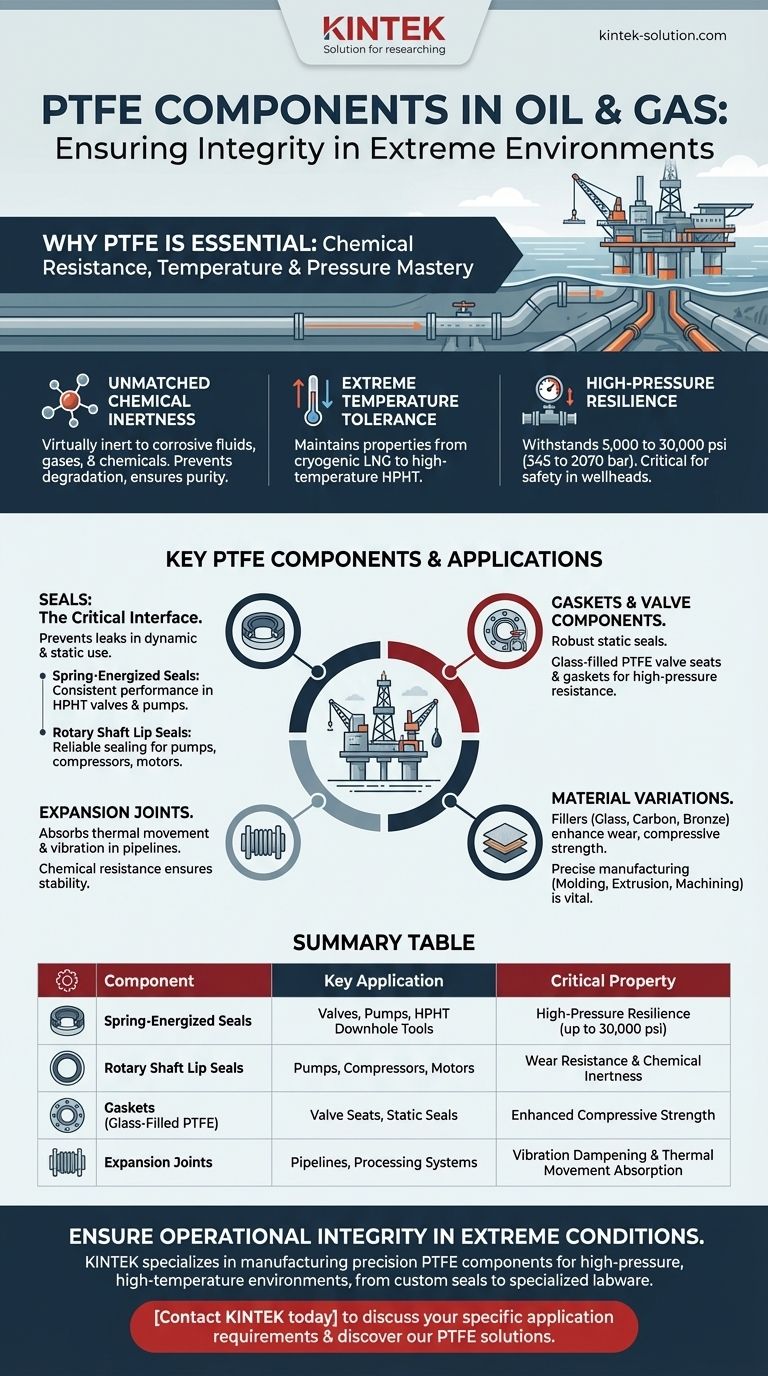

Why PTFE is Essential in Oil & Gas

The operational conditions in oil and gas exploration, extraction, and processing are among the most demanding on Earth. Materials must perform flawlessly under conditions that would cause most polymers to fail catastrophically.

Unmatched Chemical Inertness

PTFE is virtually inert to the corrosive fluids, gases, and chemicals commonly encountered in the industry. This prevents material degradation and ensures the purity of the media being transported, which is critical for operational safety and efficiency.

Extreme Temperature Tolerance

Components made from PTFE maintain their structural and sealing properties across a vast temperature spectrum. This makes them ideal for applications ranging from cryogenic LNG equipment to high-temperature, high-pressure (HPHT) downhole environments.

High-Pressure Resilience

PTFE seals and components are engineered to withstand immense pressures, often ranging from 5,000 to 30,000 psi (345 to 2070 bar). This capability is fundamental for ensuring safety and preventing leaks in critical equipment like wellheads and valves.

Key PTFE Components and Their Applications

While the material properties are impressive, their true value is realized in the specific components designed for oil and gas equipment.

Seals: The Critical Sealing Interface

Seals are the workhorses of the industry, preventing leaks in both static and dynamic applications.

PTFE spring-energized seals are frequently specified for their consistent performance and high wear resistance in equipment like valves, pumps, and downhole tools used in HPHT conditions.

PTFE rotary shaft lip seals are crucial for providing reliable sealing in rotating equipment such as pumps, compressors, and motors, protecting internal mechanisms from aggressive external environments.

Gaskets and Valve Components

In applications requiring a robust static seal, PTFE is a primary material choice.

Glass-filled PTFE is often machined into valve seats, seals, or gaskets. The addition of glass fibers significantly enhances the material's compressive strength and wear resistance, which is vital for maintaining a tight seal against high-pressure fluids and gases.

Expansion Joints

Pipelines and processing systems are subject to thermal expansion, contraction, and vibration.

PTFE expansion joints are installed to absorb these movements, ensuring system stability and preventing stress-induced failures. Their chemical resistance is essential for handling corrosive materials flowing through the system.

Understanding the Trade-offs and Material Variations

Choosing the right component involves more than just selecting PTFE; it requires understanding how the material can be modified for specific tasks.

The Role of Fillers

Pure, or virgin, PTFE is an excellent material but can be improved for specific mechanical duties.

Fillers like glass, carbon, or bronze are blended into PTFE compounds to enhance properties like wear resistance, compressive strength (to resist creep), and thermal conductivity. For instance, a glass-filled PTFE gasket will resist deformation under high pressure far better than a virgin PTFE one.

The Importance of Manufacturing Control

The performance of a final component depends heavily on the quality of its manufacturing process.

PTFE can be molded or extruded into stock shapes like rods and tubes, which are then precisely machined into finished parts. Complete control over this entire process, from compounding the raw material to final machining, is essential to meet the strict tolerances required in the oil and gas industry.

Selecting the Right PTFE Component for Your Application

Your choice of component should be directly tied to the specific operational challenge you are facing.

- If your primary focus is dynamic sealing in rotating equipment: Look to PTFE rotary shaft lip seals to ensure reliability in pumps, compressors, and motors.

- If your primary focus is static sealing in HPHT environments: Specify spring-energized seals or gaskets machined from a filled PTFE compound (like glass-filled) for superior performance.

- If your primary focus is system flexibility and vibration dampening: PTFE expansion joints are the correct solution for absorbing movement and stress in piping systems.

Ultimately, leveraging the correct PTFE component is a critical strategy for ensuring operational safety, minimizing downtime, and enhancing the reliability of equipment in the oil and gas sector.

Summary Table:

| PTFE Component | Key Application in Oil & Gas | Critical Property |

|---|---|---|

| Spring-Energized Seals | Valves, Pumps, HPHT Downhole Tools | High-Pressure Resilience (up to 30,000 psi) |

| Rotary Shaft Lip Seals | Pumps, Compressors, Motors | Wear Resistance & Chemical Inertness |

| Gaskets (e.g., Glass-Filled PTFE) | Valve Seats, Static Seals | Enhanced Compressive Strength |

| Expansion Joints | Pipelines, Processing Systems | Vibration Dampening & Thermal Movement Absorption |

Ensure your oil and gas equipment operates safely and reliably in the most extreme conditions. KINTEK specializes in manufacturing precision PTFE components—from custom seals and liners to specialized labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, guarantees components that meet the stringent demands of high-pressure, high-temperature environments.

Contact KINTEK today to discuss your specific application requirements and discover how our PTFE solutions can enhance your operational integrity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications