To put it simply, PTFE (Polytetrafluoroethylene) is used to create a wide range of laboratory equipment designed for extreme conditions. You will commonly find it in the form of chemically resistant containers, non-stick handling tools like tweezers and stir bars, and critical components for specialized instruments like vacuum pumps and electron microscope mounts.

The core reason PTFE is so prevalent in laboratories is its near-total chemical inertness and exceptionally low-friction surface. This unique combination makes it the ideal material for handling aggressive chemicals and preventing cross-contamination of sensitive samples.

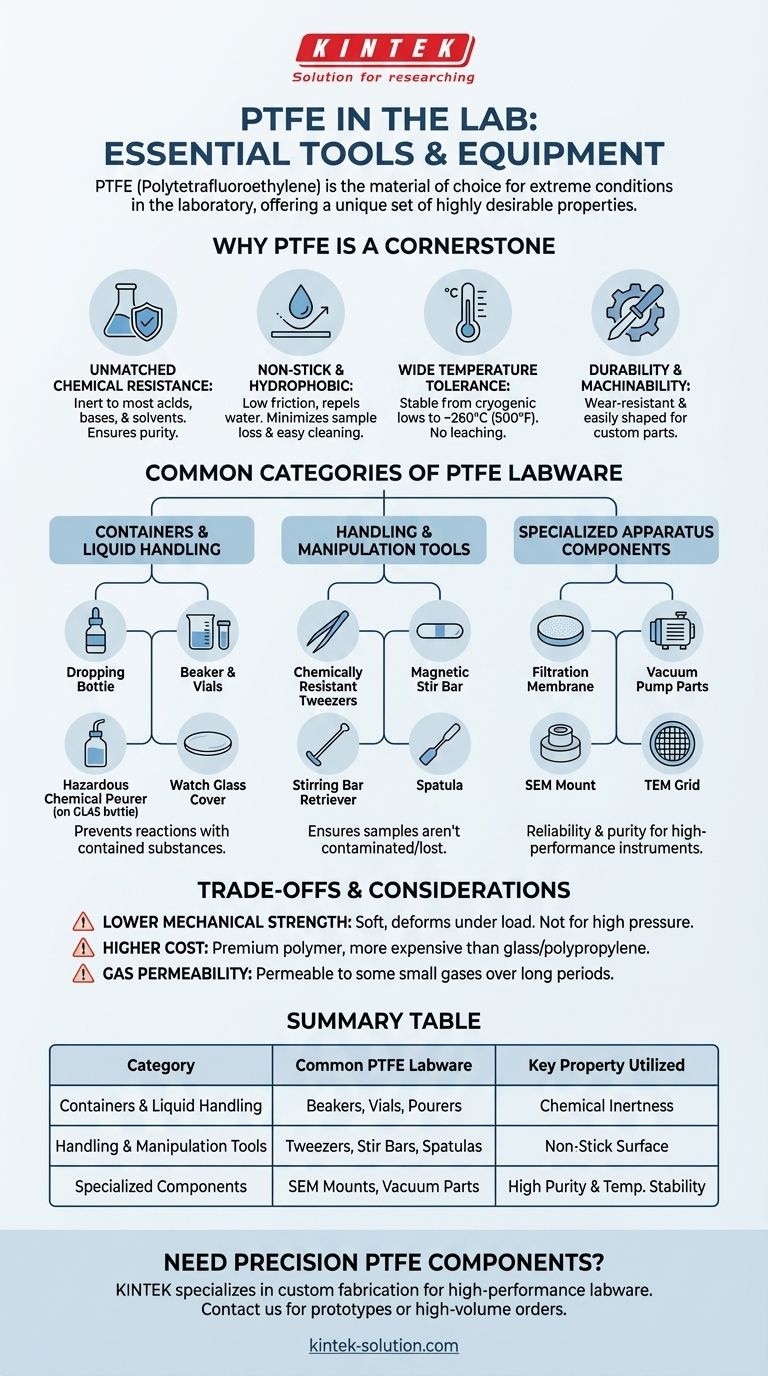

Why PTFE is a Cornerstone of the Modern Lab

Understanding the fundamental properties of PTFE reveals why it is specified for such a diverse array of lab equipment. Its molecular structure gives it a set of characteristics that are highly desirable for scientific work.

Unmatched Chemical Resistance

PTFE is virtually inert and does not react with the vast majority of chemicals, including highly corrosive acids, bases, and organic solvents.

This is why it is the material of choice for items like hazardous chemical bottle pourers and specimen storage containers, ensuring sample purity and user safety.

Non-Stick and Hydrophobic Surface

PTFE has one of the lowest coefficients of friction of any solid, giving it its famous non-stick quality. Its surface is also hydrophobic, meaning it repels water.

This is critical for applications like magnetic stir bars and tweezers, as it minimizes sample loss and makes cleaning exceptionally easy, reducing the risk of cross-contamination between experiments.

Wide Temperature Tolerance

PTFE maintains its properties across a broad range of temperatures. It remains stable and functional in applications from cryogenic lows to highs of around 260°C (500°F).

This versatility allows it to be used in equipment for both heating and cooling processes without degrading or leaching contaminants.

Durability and Machinability

While known for its softness, PTFE is a durable and wear-resistant polymer. It is easily machined into precise and complex shapes.

This property enables the creation of custom components for sophisticated equipment, such as SEM mounts, TEM grids, and parts for vacuum pumps and filtration devices.

Common Categories of PTFE Labware

Based on its properties, PTFE equipment can be grouped into several key functional categories found in almost any lab.

Containers and Liquid Handling

This category leverages PTFE's inertness to prevent any reaction with the contained substance.

- Dropping bottles

- Beakers and vials

- Hazardous chemical pourers (for GL30, GL38, GL45 bottles)

- Watch glass covers

Handling and Manipulation Tools

These tools rely on the non-stick surface of PTFE to ensure that samples are not contaminated or lost during transfer.

- Chemically resistant tweezers

- Magnetic stirring bars

- Stirring bar retrievers

- Spatulas

Specialized Apparatus Components

For high-performance instruments, the reliability and purity of PTFE are essential.

- Filtration devices and membranes

- Components for vacuum products and pumps

- Specimen mounts for Scanning Electron Microscopy (SEM)

- Grids for Transmission Electron Microscopy (TEM)

Understanding the Trade-offs

No material is perfect, and choosing PTFE requires an awareness of its limitations. Being objective about these trade-offs is key to using it effectively.

Lower Mechanical Strength

Compared to materials like glass or stainless steel, PTFE is soft and has low structural rigidity. It can deform or "creep" under a sustained load, making it unsuitable for high-pressure or load-bearing structural applications.

Higher Cost

PTFE is a premium polymer, and labware made from it is significantly more expensive than alternatives made from glass, polypropylene, or polyethylene. Its use is typically justified by the demands of the application.

Gas Permeability

While excellent at containing liquids, PTFE is somewhat permeable to certain small gas molecules over long periods. This can be a factor in the long-term storage of specific gas-sensitive compounds.

Making the Right Choice for Your Application

Selecting the correct labware material is a critical decision that impacts the integrity of your results. Use these guidelines to determine if PTFE is the right choice.

- If your primary focus is handling highly corrosive or reactive chemicals: PTFE is the safest and most reliable choice due to its unmatched chemical inertness.

- If you are working with "sticky" biological samples or expensive reagents: The non-stick surface of PTFE will minimize sample loss and ensure accurate transfers.

- If your budget is the main constraint for general, non-aggressive use: Consider more cost-effective materials like glass or polypropylene for routine tasks.

- If you require high structural rigidity or high-pressure tolerance: You should evaluate materials like PEEK, stainless steel, or reinforced composites instead of PTFE.

Ultimately, understanding the unique properties of PTFE empowers you to select the right tool for the most demanding scientific challenges.

Summary Table:

| Category | Common PTFE Labware | Key Property Utilized |

|---|---|---|

| Containers & Liquid Handling | Beakers, Vials, Bottle Pourers | Chemical Inertness |

| Handling & Manipulation Tools | Tweezers, Stir Bars, Spatulas | Non-Stick Surface |

| Specialized Components | SEM Mounts, Filtration Devices, Vacuum Pump Parts | High Purity & Temperature Stability |

Need precision PTFE components for your demanding applications?

KINTEK specializes in the custom fabrication of high-performance PTFE labware and components for the semiconductor, medical, laboratory, and industrial sectors. Whether you require standard items like seals and liners or custom prototypes for specialized instruments, we deliver the chemical resistance, purity, and durability your work demands.

Contact KINTEK today to discuss your project requirements—from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- In which industries is PTFE commonly used? Key Applications for Chemical & Thermal Resistance

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications