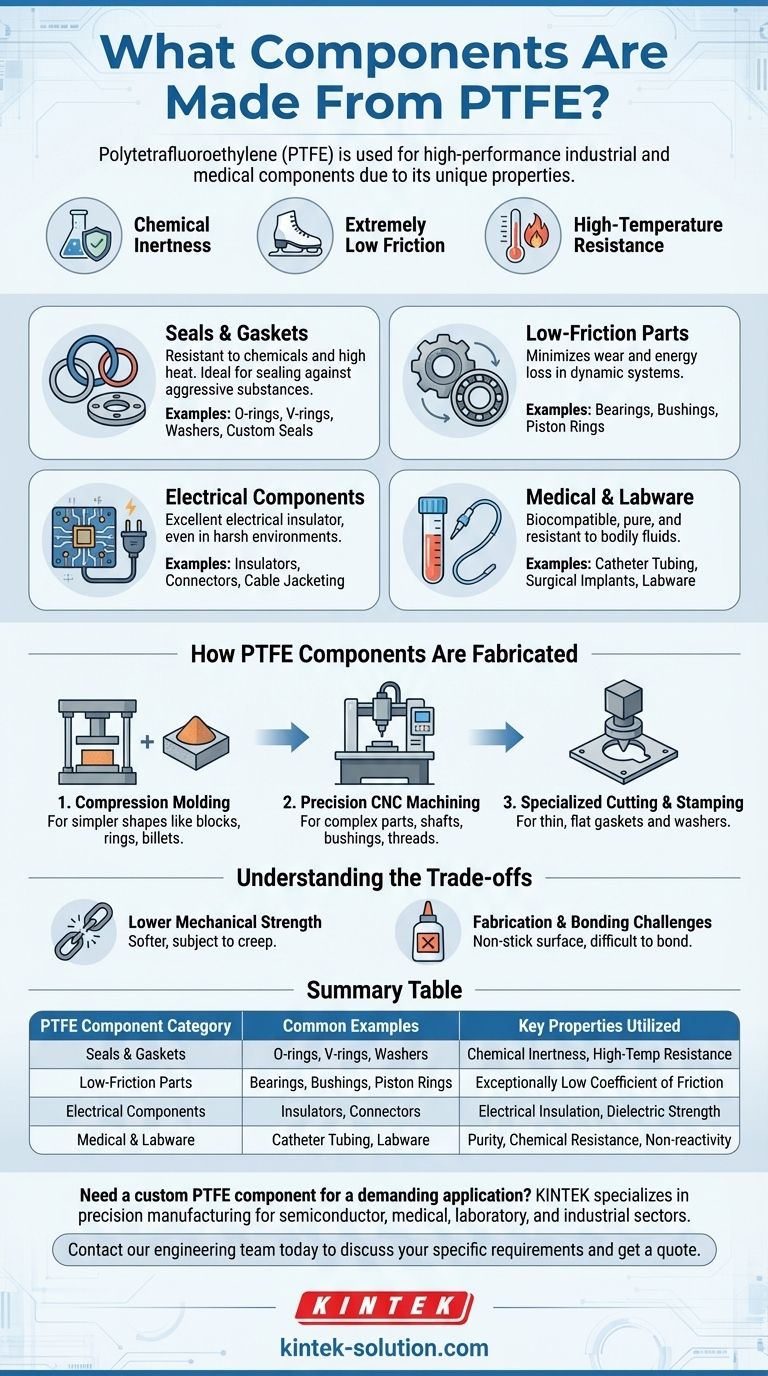

In short, Polytetrafluoroethylene (PTFE) is used to create a wide range of high-performance industrial and medical components. Common examples include seals, gaskets, O-rings, V-rings, washers, bearings, bushings, insulators, and precision parts like nozzles and medical catheter tubing.

The specific components made from PTFE are a direct result of its unique properties: near-total chemical resistance, an extremely low coefficient of friction, and high-temperature tolerance. The final form is achieved through molding, precision machining, or specialized cutting processes.

Why PTFE is Chosen for These Components

The decision to use PTFE is almost always driven by a need for performance under demanding conditions where other materials would fail. Its core characteristics make it ideal for specific functions.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals and solvents. This makes it a premier material for components that handle corrosive substances.

This property is why it's the material of choice for gaskets, seals, and O-rings in chemical processing equipment. In the medical field, its purity and resistance to bodily fluids make it valuable for devices like catheters, which must remain sterile and non-reactive.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slipperiness" is invaluable for parts that slide against each other.

This is the primary reason for its use in bearings, piston rings, and V-rings. These components reduce energy loss and wear in machinery, from industrial pumps to automotive engines.

High-Temperature and Electrical Resistance

PTFE maintains its integrity over a wide temperature range and is an excellent electrical insulator. It does not absorb water and has high dielectric strength.

This makes it the perfect material for high-performance electrical insulators and connectors, especially in applications where temperature and environmental stability are critical.

How PTFE Components Are Fabricated

Raw PTFE material, often in the form of stock rods, sheets, or tubes, must be shaped into a final component. This is typically done through two primary methods: molding and machining.

Compression Molding

For simpler shapes, compression molding is a common first step. Raw PTFE powder is compressed into a mold and heated (sintered) to create a solid, basic shape.

This process is often used to create semi-finished products like blocks, rings, and billets that may be machined later for their final dimensions.

Precision CNC Machining

For more complex or high-tolerance parts, machining is required. CNC (Computer Numerical Control) equipment provides exceptional accuracy.

CNC turning is used to create cylindrical parts like shafts, bushings, and rings. CNC milling carves out more intricate designs, patterns, and cavities. Drilling and tapping are used to create precise holes and threads.

Specialized Cutting and Stamping

For thin, flat components, other fabrication methods are more efficient.

Processes like die cutting, stamping, and laser cutting are used to quickly produce large quantities of parts like gaskets and washers from PTFE sheets.

Understanding the Trade-offs

While PTFE's properties are remarkable, it is not a universal solution. Understanding its limitations is key to using it effectively.

Lower Mechanical Strength

Compared to engineering plastics like nylon or PEEK, PTFE is relatively soft and has poor wear resistance against abrasive particles. It can also be subject to "creep," or deformation under a sustained load.

Fabrication and Bonding Challenges

Because of its non-stick surface, bonding PTFE to other materials is notoriously difficult and requires specialized surface treatments like chemical etching. Its softness can also present unique challenges during machining that require experienced technicians.

Making the Right Choice for Your Application

Selecting a PTFE component depends entirely on the problem you need to solve.

- If your primary focus is sealing against aggressive chemicals: Your best options are PTFE gaskets, O-rings, and custom seals.

- If your primary focus is reducing friction in dynamic systems: Look to PTFE bearings, bushings, piston rings, and V-rings.

- If your primary focus is electrical insulation in a harsh environment: PTFE insulators and connectors are the ideal choice.

Ultimately, leveraging PTFE is about applying its unique strengths to solve the most demanding engineering challenges.

Summary Table:

| PTFE Component Category | Common Examples | Key Properties Utilized |

|---|---|---|

| Seals & Gaskets | O-rings, V-rings, Washers | Chemical Inertness, High-Temp Resistance |

| Low-Friction Parts | Bearings, Bushings, Piston Rings | Exceptionally Low Coefficient of Friction |

| Electrical Components | Insulators, Connectors | Electrical Insulation, Dielectric Strength |

| Medical & Labware | Catheter Tubing, Labware | Purity, Chemical Resistance, Non-reactivity |

Need a custom PTFE component for a demanding application?

KINTEK specializes in the precision manufacturing of PTFE seals, liners, labware, and other critical components for the semiconductor, medical, laboratory, and industrial sectors. We combine expert fabrication techniques—from prototyping to high-volume production—with a deep understanding of material science to deliver parts that perform under extreme conditions.

Contact our engineering team today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance