In short, PTFE coated bolts and screws offer a significant advantage by drastically reducing friction. This low-friction surface prevents the threads from galling or seizing together under high pressure, which ensures smoother installation, more reliable performance, and far easier disassembly, even after long-term exposure to harsh conditions.

The core benefit of a PTFE coating is not just about making a bolt "slippery." It's about transforming unpredictable friction into a known, low value, which allows you to achieve precise clamping forces and protect the fastener's integrity throughout its entire service life.

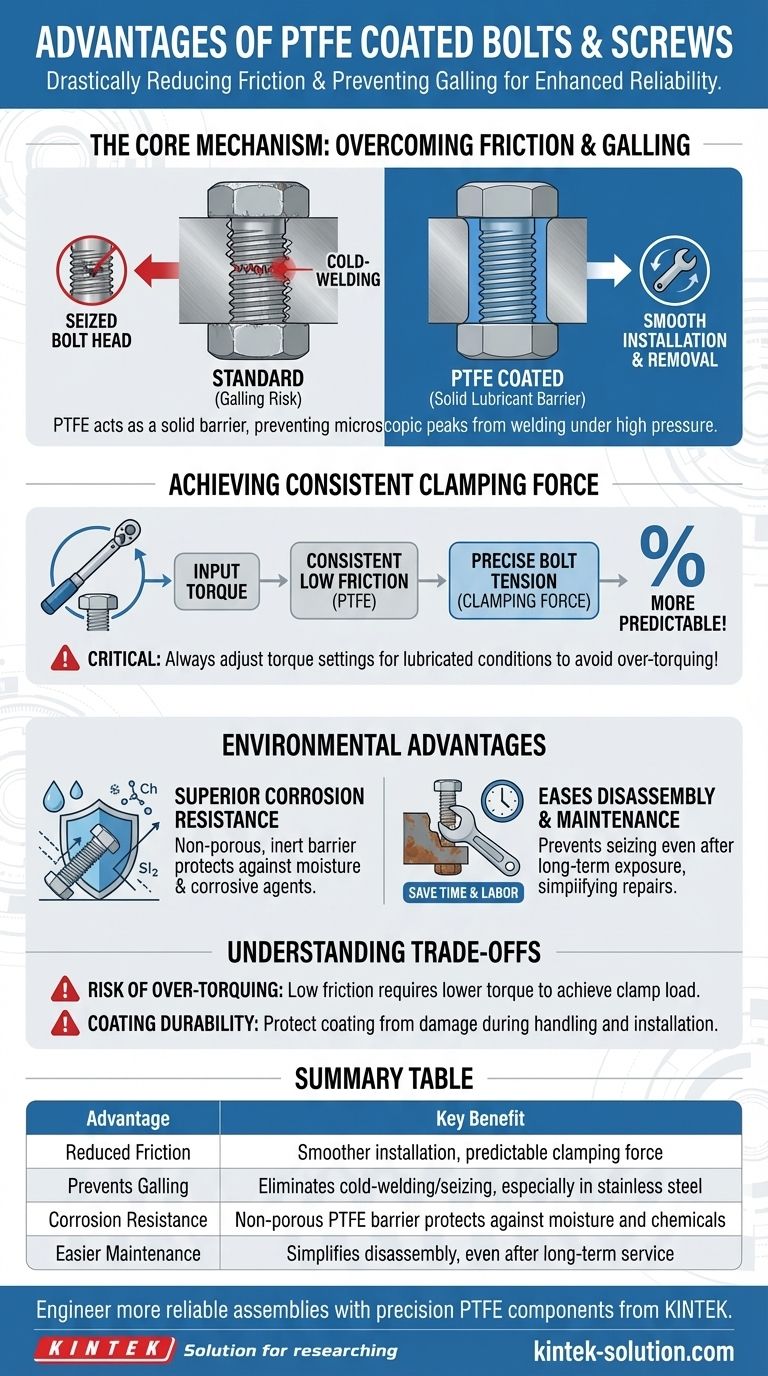

The Core Mechanism: Overcoming Friction and Galling

The primary job of a threaded fastener is to create and maintain a specific clamping force. However, friction works directly against this goal. A PTFE coating fundamentally alters the physics of the assembly in your favor.

What is Galling?

Galling, also known as cold-welding, occurs when two metal surfaces under high pressure and friction essentially weld themselves together. This is especially common with stainless steel fasteners.

The result is seized threads that can damage the assembly or cause the bolt to shear off during installation or removal.

How PTFE Prevents Galling

A PTFE coating acts as a solid lubricant barrier between the male and female threads.

This barrier physically prevents the microscopic peaks on the metal surfaces from making direct contact, thereby eliminating the root cause of friction and galling.

Achieving Consistent Torque and Clamping Force

A surprising amount of the torque you apply to a bolt—often over 85%—is consumed just to overcome friction under the bolt head and in the threads.

By providing a consistently low coefficient of friction, PTFE ensures that a much greater and more predictable percentage of your input torque is converted into useful bolt tension, which is the force that actually clamps the joint together.

Beyond Friction: The Environmental Advantages

While friction reduction is the primary mechanical benefit, PTFE coatings also provide a robust shield against environmental threats.

Superior Corrosion Resistance

The PTFE coating creates a non-porous, chemically inert barrier over the entire fastener.

This shield protects the base metal from exposure to moisture, salt spray, and other corrosive agents, dramatically extending the fastener's life and preventing rust from seizing the threads.

Easing Disassembly and Maintenance

The combined anti-galling and anti-corrosion properties make a tremendous difference during maintenance and teardowns.

Fasteners that have been in service for years can often be removed with standard tools, saving significant time, reducing labor costs, and eliminating the need to cut or drill out seized bolts.

Understanding the Trade-offs

While highly effective, using PTFE coated fasteners requires a clear understanding of their properties to avoid common pitfalls.

The Risk of Over-Torquing

The most critical consideration is the fastener's low friction. If you use standard "dry" torque specifications, you will inadvertently apply a dangerously high clamp load.

This can stretch the bolt beyond its yield point, damage the clamped components, or lead to premature failure. Always use torque calculations specifically adjusted for lubricated or PTFE-coated conditions.

Coating Durability

The protective coating can be damaged by improper handling or installation techniques, such as using worn or sharp-edged sockets.

Care must be taken to preserve the coating's integrity to realize its full benefits. A compromised coating loses its anti-corrosion and anti-galling properties at the point of damage.

Making the Right Choice for Your Goal

Specifying PTFE coated fasteners is a strategic decision to enhance reliability in specific, challenging scenarios.

- If your primary focus is preventing seizure in high-pressure assemblies: The anti-galling property is your key benefit, particularly when working with stainless steel or other gall-prone alloys.

- If your primary focus is reliability in corrosive environments: The coating provides an essential chemical and moisture barrier, ensuring long-term fastener integrity and simplifying future maintenance.

- If your primary focus is achieving precise and repeatable clamp loads: The consistent low friction ensures your torque wrench readings translate directly and reliably into the bolt tension your design requires.

By understanding how PTFE coatings manage friction, you can proactively engineer more reliable, durable, and serviceable bolted joints.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Reduced Friction | Smoother installation, predictable clamping force |

| Prevents Galling | Eliminates cold-welding/seizing, especially in stainless steel |

| Corrosion Resistance | Non-porous PTFE barrier protects against moisture and chemicals |

| Easier Maintenance | Simplifies disassembly, even after long-term service |

Engineer more reliable assemblies with precision PTFE components from KINTEK.

Are you designing for the semiconductor, medical, laboratory, or industrial sectors? Our expertise in custom PTFE fabrication—from prototypes to high-volume orders—ensures your fasteners and components provide the exact anti-galling and corrosion-resistant properties your application demands.

Contact KINTEK today to discuss your specific requirements and achieve predictable, long-lasting performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications