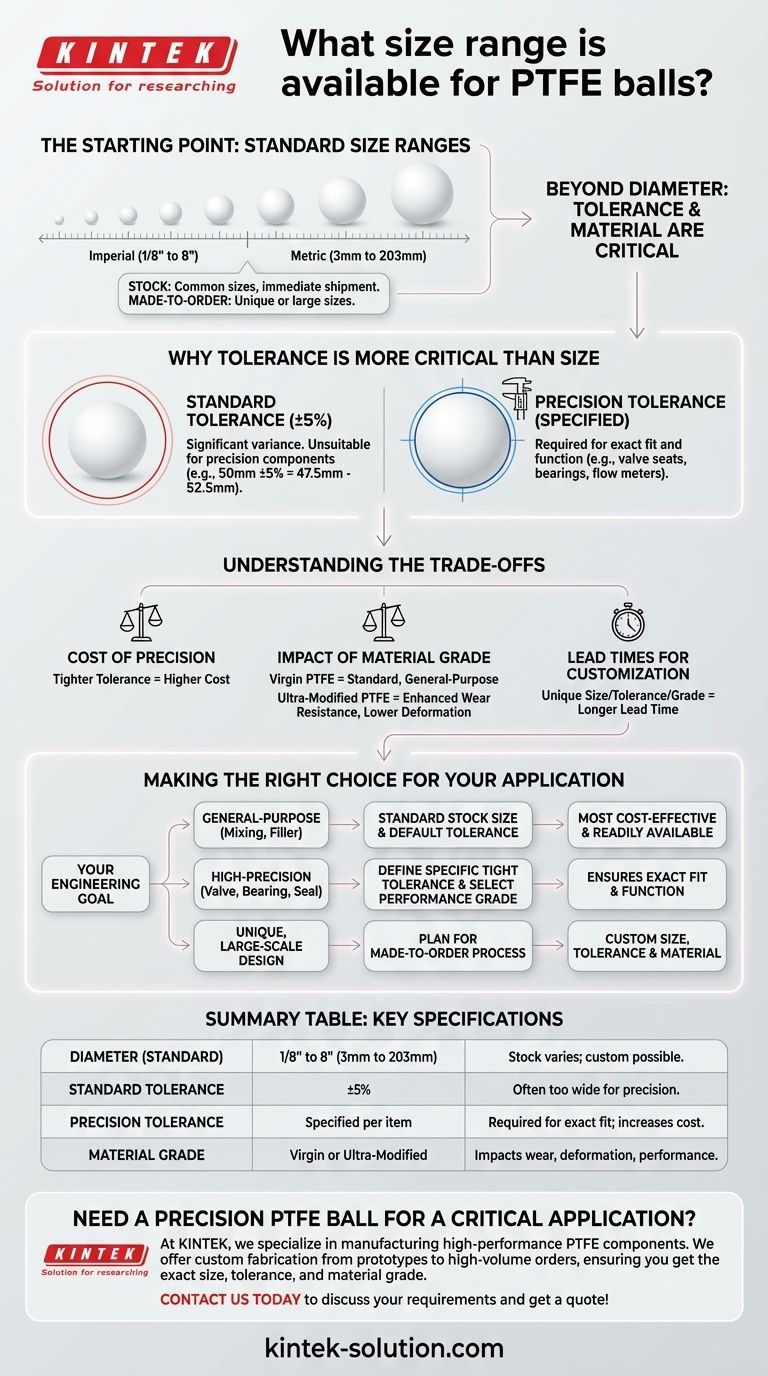

PTFE balls are commercially available in a wide range of standard sizes, typically from 1/8 inch (approximately 3mm) up to 8 inches (around 203mm) in diameter. Both imperial and metric measurements are common, with stock availability varying by supplier. For unique requirements or large quantities, sizes outside this range can often be produced on a made-to-order basis.

The listed size range of a PTFE ball is only the starting point. The true determinants of performance for any engineering application are the manufacturing tolerance and the specific grade of PTFE material selected.

Understanding the Standard Size Ranges

Polytetrafluoroethylene (PTFE) is an incredibly versatile material, and its availability in various ball sizes reflects its widespread use in everything from laboratory equipment to industrial valves.

Imperial and Metric Availability

Most suppliers offer sizes in both imperial (inch) and metric (millimeter) units to serve global markets. The common ranges, such as 1/8" to 8" and 3mm to 100mm, are largely equivalent and cover the majority of standard industrial needs.

Stock vs. Made-to-Order

Common fractional or whole-number sizes are typically kept in stock for immediate shipment. However, if your application requires a very large diameter or a highly specific intermediate size, it will likely be a custom, made-to-order production run.

Why Tolerance Is More Critical Than Size

Simply specifying a diameter is insufficient for most technical applications. The allowable deviation from that diameter, known as tolerance, is where precision is truly defined.

The Standard Diameter Tolerance

The default manufacturing tolerance for many PTFE balls is ±5%. This is a significant variance that is unsuitable for precision components.

For a 50mm ball, a ±5% tolerance means the actual diameter could be anywhere from 47.5mm to 52.5mm. This range is often too wide for applications requiring a specific fit or seal.

Specifying for Precision

For applications like valve seats, bearings, or flow meters, you must request a precision diameter tolerance. This is specified on a per-item basis with your supplier and ensures the component functions correctly within your assembly.

Understanding the Trade-offs

Choosing the right PTFE ball involves balancing performance requirements with practical constraints like cost and lead time.

The Cost of Precision

Tighter tolerances require more precise manufacturing and quality control processes, which directly increases the cost per unit. Standard-tolerance balls are always the most economical option.

The Impact of Material Grade

The grade of PTFE also plays a critical role. Virgin PTFE is the standard, general-purpose grade. For more demanding applications requiring enhanced wear resistance or lower deformation under load, an Ultra-Modified grade may be necessary.

Lead Times for Customization

Any deviation from a standard stock item—whether it's a unique size, a precision tolerance, or a special material grade—will result in longer lead times due to custom production setups.

Making the Right Choice for Your Application

To select the correct component, align your specifications with your primary engineering goal.

- If your primary focus is a general-purpose application (e.g., mixing beads, filler material): A standard stock size with a default tolerance is the most cost-effective and readily available solution.

- If your primary focus is a high-precision mechanism (e.g., a check valve, bearing, or seal): You must define a specific, tight diameter tolerance and select the PTFE grade that meets your performance criteria.

- If your primary focus is a unique, large-scale design: Plan for a made-to-order process and work directly with a manufacturer to define the size, tolerance, and material for your specific needs.

By looking beyond the nominal diameter to include tolerance and material grade, you ensure the component you source will perform exactly as your design requires.

Summary Table:

| Specification | Common Range / Standard | Key Consideration |

|---|---|---|

| Diameter (Standard) | 1/8" to 8" (3mm to 203mm) | Stock availability varies; custom sizes are possible. |

| Standard Tolerance | ±5% | Often too wide for precision applications like seals or bearings. |

| Precision Tolerance | Specified per item | Required for exact fit and function; increases cost. |

| Material Grade | Virgin (Standard) or Ultra-Modified | Grade selection impacts wear resistance, deformation, and performance. |

Need a precision PTFE ball for a critical application?

At KINTEK, we specialize in manufacturing high-performance PTFE components like seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. We understand that the right size, tolerance, and material grade are essential for your success.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact component your design requires. Don't compromise on performance—let our expertise in precision production work for you.

Contact us today to discuss your specific PTFE ball requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key chemical properties of PTFE balls? Unmatched Chemical & Thermal Stability

- What are the advantages of PTFE balls over metals or alloys? Superior Chemical & Friction Resistance

- Why are PTFE balls particularly suitable for high-performance applications? Key Properties & Selection Guide

- What are the available grades of PTFE balls? Choose the Right Grade for Your Application

- How do the chemical properties of PTFE balls influence their performance? Unmatched Durability in Harsh Environments