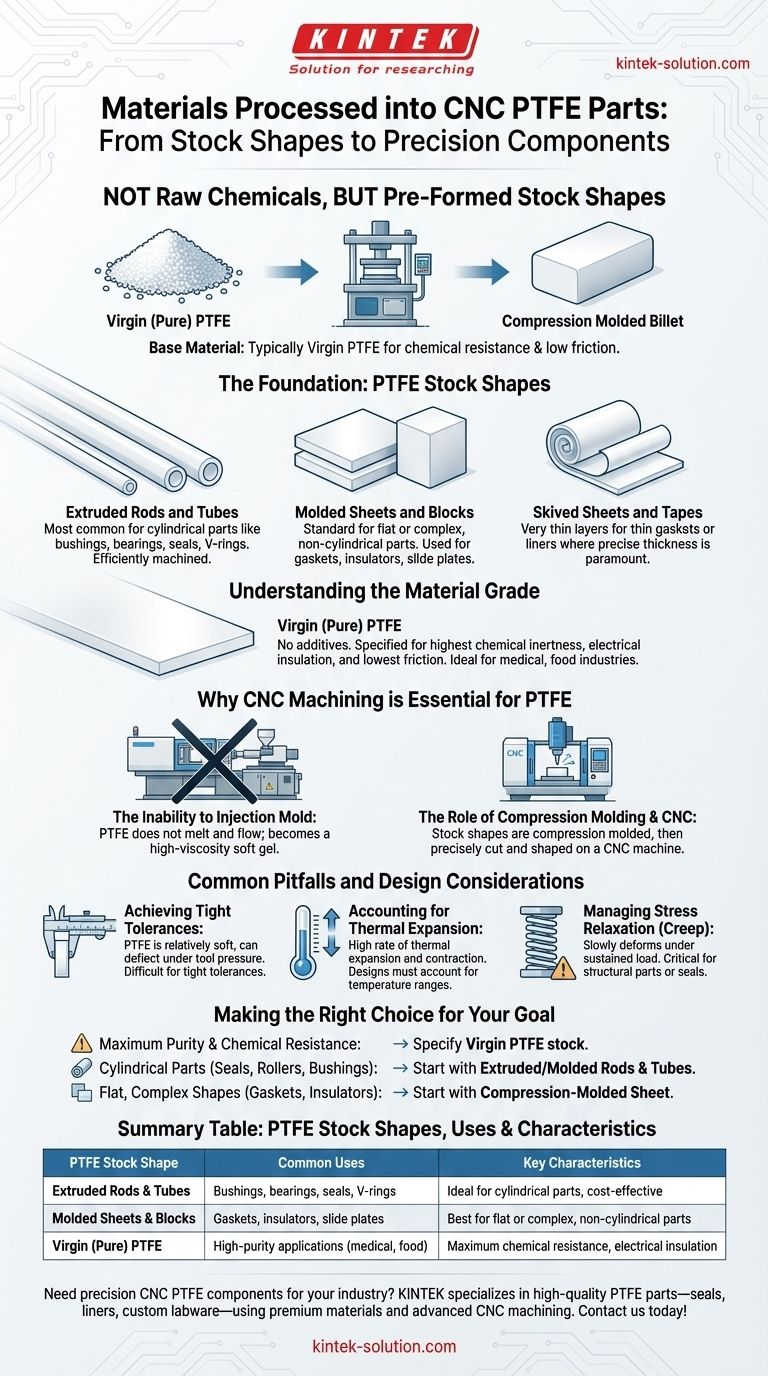

The materials processed into CNC PTFE parts are not raw chemicals, but pre-formed stock shapes. These fundamental forms include extruded or molded rods, tubes, and sheets. The base material for these shapes is typically virgin (pure) Polytetrafluoroethylene (PTFE), selected for its exceptional chemical resistance and low-friction properties.

The critical distinction is that you don't machine PTFE from a raw polymer. Instead, you start with a solid, pre-formed block or cylinder of a specific PTFE grade, which is then precisely cut and shaped on a CNC machine to create the final component.

The Foundation: PTFE Stock Shapes

CNC machining requires a solid piece of material, known as "stock" or a "billet," to begin work. PTFE is processed into these standard shapes, which then serve as the raw material for any CNC operation.

Extruded Rods and Tubes

These are the most common starting points for cylindrical parts. Components like bushings, bearings, seals, and V-rings are efficiently machined from stock rods and tubes.

Molded Sheets and Blocks

For flat or complex, non-cylindrical parts, a molded sheet is the standard. These thick plates provide a stable base for milling gaskets, insulators, slide plates, or any component with a custom footprint.

Skived Sheets and Tapes

While less common for complex CNC parts, skived sheets are very thin layers of PTFE shaved from a larger block. They are often used for creating thin gaskets or liners where precise thickness is paramount.

Understanding the Material Grade

The performance of a CNC part is dictated by the quality of the stock material it was machined from. For PTFE, the most common and fundamental grade is virgin PTFE.

Virgin (Pure) PTFE

As the name implies, this is pure Polytetrafluoroethylene without any additives. It is specified when the application demands the highest levels of chemical inertness, electrical insulation, or the lowest coefficient of friction. Many high-purity applications, like those in the medical or food industries, mandate virgin PTFE.

Why CNC Machining is Essential for PTFE

Unlike common plastics, PTFE has unique thermal properties that dictate how it can be formed into complex parts. This is why CNC machining is the default method for creating precise components.

The Inability to Injection Mold

PTFE is not a true thermoplastic. It does not melt and flow like plastics such as nylon or polypropylene. When heated, it becomes a soft gel but maintains a very high viscosity, making it impossible to inject into a mold for complex shapes.

The Role of Compression Molding

The stock shapes themselves—the rods, tubes, and sheets—are typically created through a process called compression molding. PTFE powder is compressed under immense pressure and then heated in a process called sintering to fuse the particles into a solid, dense block. This block is the material that ultimately feeds the CNC machine.

Common Pitfalls and Design Considerations

Machining PTFE is not without its challenges. Its unique properties require careful design and process control to achieve the desired outcome. An expert advisor would be remiss not to highlight these points.

Achieving and Holding Tight Tolerances

PTFE is a relatively soft material, which can make achieving extremely tight tolerances difficult. The material can deflect under tool pressure if not handled correctly.

Accounting for Thermal Expansion

PTFE has a very high rate of thermal expansion and contraction compared to metals. Designs must account for the temperature range of the final application to ensure the part fits and functions correctly.

Managing Stress Relaxation (Creep)

Under sustained load, PTFE can slowly deform over time, a behavior known as creep or stress relaxation. This is a critical consideration for structural components or seals that are under constant pressure.

Making the Right Choice for Your Goal

Selecting the correct starting material is the first step toward a successful part. Your decision should be based on the geometry and functional requirements of the final component.

- If your primary focus is maximum purity and chemical resistance: Specify that your parts must be machined from virgin PTFE stock.

- If you are creating cylindrical parts like seals, rollers, or bushings: Starting with extruded or molded PTFE rods and tubes is the most cost-effective and efficient path.

- If your design involves flat, complex shapes like custom gaskets or insulators: Your starting point should be a compression-molded PTFE sheet.

Ultimately, understanding the journey from a simple stock shape to a precision component is key to engineering successful PTFE parts.

Summary Table:

| PTFE Stock Shape | Common Uses | Key Characteristics |

|---|---|---|

| Extruded Rods & Tubes | Bushings, bearings, seals, V-rings | Ideal for cylindrical parts, cost-effective |

| Molded Sheets & Blocks | Gaskets, insulators, slide plates | Best for flat or complex, non-cylindrical parts |

| Virgin (Pure) PTFE | High-purity applications (medical, food) | Maximum chemical resistance, electrical insulation |

Need precision CNC PTFE components for your industry?

KINTEK specializes in manufacturing high-quality PTFE parts—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We use premium materials and advanced CNC machining to deliver parts that meet exact specifications, from prototypes to high-volume orders.

Contact us today to discuss your project requirements and benefit from our expertise in custom PTFE fabrication!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials