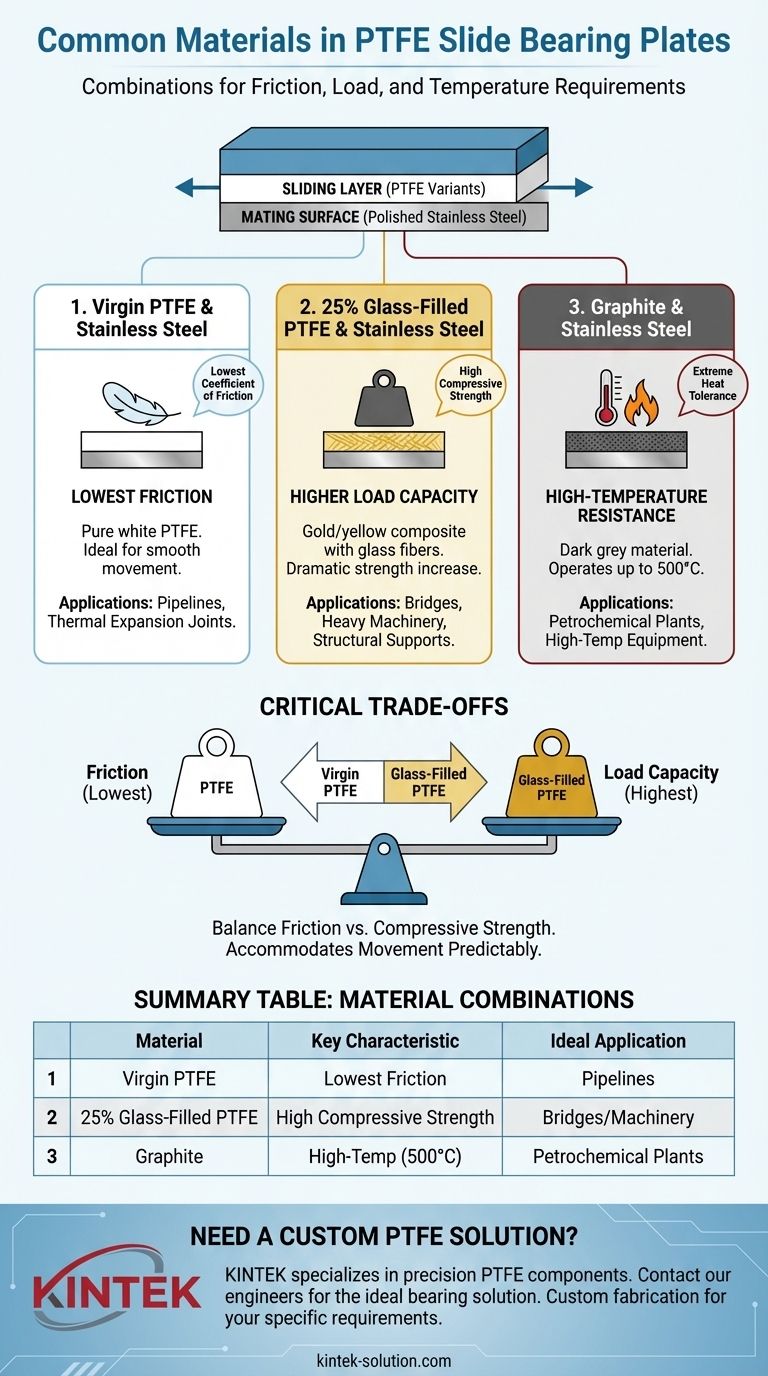

The most common materials used in PTFE slide bearing plates involve specific pairings designed for different performance needs. The three primary combinations are virgin Polytetrafluoroethylene (PTFE) on stainless steel for the lowest friction, 25% glass-filled PTFE on stainless steel for higher load capacity, and graphite on stainless steel for high-temperature applications.

The selection of a specific material combination for a PTFE slide bearing is not arbitrary. It is a calculated engineering decision based on a critical balance between the required load capacity, acceptable friction levels, and the operational temperature of the application.

Deconstructing the Slide Bearing Assembly

A PTFE slide bearing is a two-part system designed to accommodate movement. Understanding both parts is key to understanding the material choices.

The Sliding Layer: PTFE Variants

Polytetrafluoroethylene, or PTFE, is a synthetic fluoropolymer famous for its incredibly low coefficient of friction. You may know it by the brand name Teflon.

Its pure, or virgin, form is a white solid that offers the lowest friction possible.

To enhance its mechanical properties, PTFE is often mixed with fillers. Adding glass fibers creates a composite material (often gold in color) that significantly increases the bearing's ability to withstand high pressure.

The Mating Surface: Polished Stainless Steel

The PTFE layer almost always slides against a highly polished stainless steel plate.

This material is chosen for its combination of a smooth surface, which is critical for low-friction movement, and its excellent corrosion resistance, ensuring long-term reliability in exposed environments.

Key Material Combinations and Their Use Cases

The specific variant of the sliding material dictates the bearing's performance characteristics and its ideal application.

Virgin PTFE for Lowest Friction

This is the most fundamental combination, prized for having the lowest coefficient of friction.

It is the ideal choice when facilitating smooth, easy movement is the absolute top priority, such as in pipelines that must accommodate thermal expansion and contraction with minimal stress.

Glass-Filled PTFE for Higher Loads

By adding approximately 25% glass fiber aggregate to the PTFE, the material's compressive strength is dramatically increased.

This composite is essential for applications where heavy loads are a factor, such as supporting bridge girders, heavy machinery, or large structural elements in buildings.

Graphite for High-Temperature Environments

For applications exposed to extreme heat, standard PTFE is unsuitable. In these cases, graphite is used as the sliding material.

Graphite can operate in temperatures up to 500°C, making it the standard for petrochemical plants and other high-temperature industrial equipment.

Understanding the Critical Trade-offs

Choosing a material is an exercise in balancing competing requirements. There is no single "best" material, only the right material for the specific job.

Friction vs. Compressive Strength

There is a direct trade-off between friction and load-bearing capacity.

Virgin PTFE offers the lowest friction but has the lowest compressive strength. Adding fillers like glass fiber increases load capacity but also slightly increases the coefficient of friction.

Accommodating Movement

The fundamental purpose of these bearings is to allow for controlled movement. This can be slow thermal expansion in a pipeline, lateral seismic movement in a building, or axial shifts in heavy equipment.

The material choice ensures this movement occurs predictably and without transferring damaging stress to the larger structure.

Making the Right Choice for Your Application

Your selection must be guided by the primary demand of your engineering challenge.

- If your primary focus is minimal friction: Virgin PTFE on polished stainless steel is the definitive choice for the smoothest possible movement.

- If your primary focus is high load capacity: A 25% glass-filled PTFE composite provides the necessary compressive strength for heavy structural support.

- If your primary focus is extreme heat resistance: Graphite paired with stainless steel is the only option engineered for reliable high-temperature service.

Ultimately, selecting the correct slide bearing material is a critical step in ensuring the long-term stability and integrity of your structure or equipment.

Summary Table:

| Material Combination | Key Characteristic | Ideal Application |

|---|---|---|

| Virgin PTFE on Stainless Steel | Lowest Coefficient of Friction | Pipelines, Thermal Expansion Joints |

| 25% Glass-Filled PTFE on Stainless Steel | High Compressive Strength | Bridges, Heavy Machinery, Structural Supports |

| Graphite on Stainless Steel | High-Temperature Resistance (up to 500°C) | Petrochemical Plants, High-Temperature Equipment |

Need a Custom PTFE Slide Bearing Solution?

Selecting the right material is critical for the performance and longevity of your project. KINTEK specializes in the precision manufacturing of PTFE components, including custom slide bearing plates, seals, and liners.

We serve the semiconductor, medical, laboratory, and industrial sectors, offering custom fabrication from prototypes to high-volume orders. Our expertise ensures you get a bearing solution perfectly matched to your load, friction, and temperature requirements.

Let our engineers help you specify the ideal bearing for your application. Contact KINTEK today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers