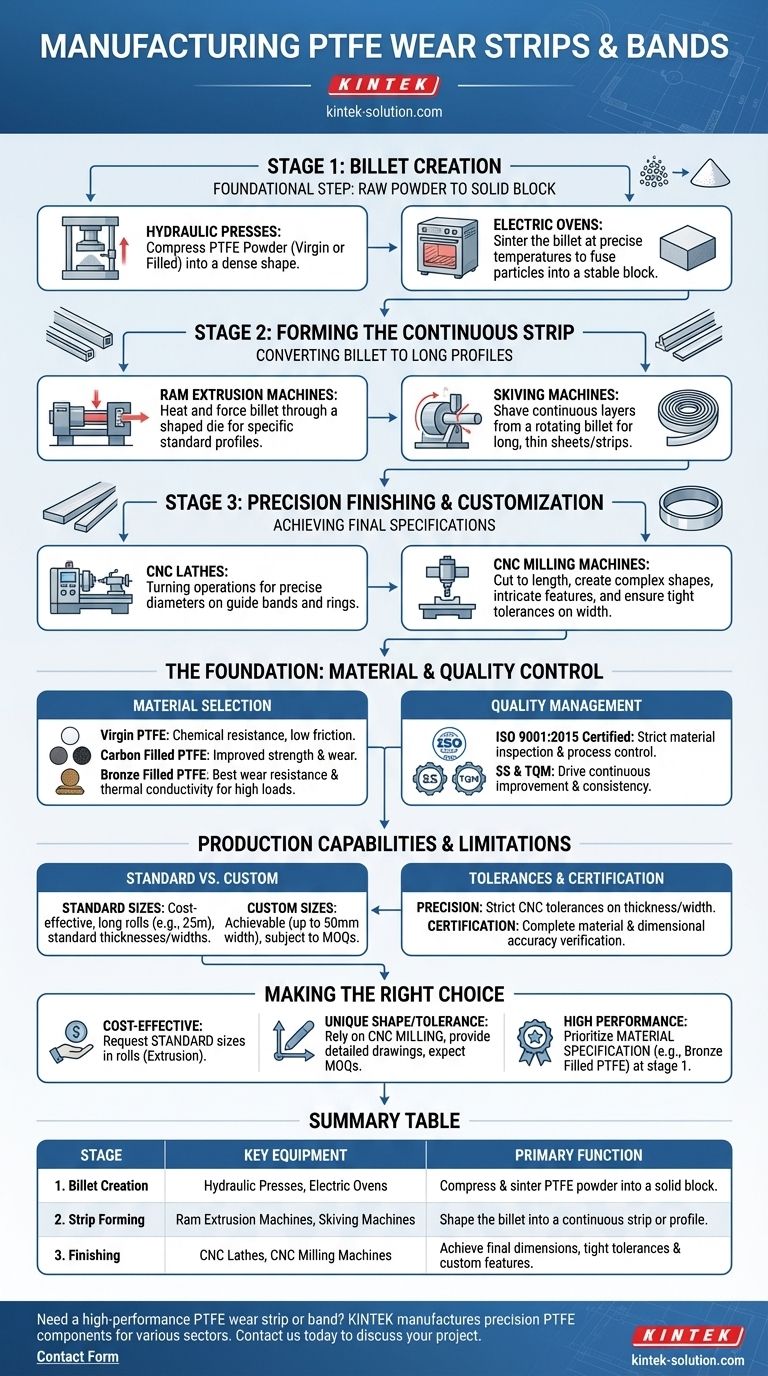

To produce PTFE wear strips and bands, manufacturing facilities rely on a sequence of specialized machinery. The core equipment includes Hydraulic Presses and Electric Ovens for creating the initial PTFE billet, followed by Ram Extrusion or Skiving Machines to form the basic strip shape, and finally CNC Lathes and Milling Machines for precision finishing and customization. This integrated setup allows for the entire production process to happen under one roof.

The manufacturing of a PTFE wear strip is not a single action but a multi-stage process. Understanding this workflow—from raw material consolidation to precision machining—is the key to specifying a product that meets your exact dimensional and performance requirements.

The Manufacturing Workflow: From Raw Powder to Finished Part

Producing a high-quality wear strip involves several distinct phases, each requiring specific equipment and controls. The process transforms raw PTFE powder into a precise, functional component.

Stage 1: Creating the PTFE Billet

Before a strip can be cut, a solid block of PTFE, known as a billet, must be created. This is the foundational step.

Hydraulic Presses are used to compress the chosen PTFE powder (whether virgin or filled) into a dense, solid shape under immense pressure. This initial form is mechanically weak.

Electric Ovens then perform a critical process called sintering. The compressed billet is heated to a precise temperature for a specific duration, fusing the PTFE particles into a solid, stable, and durable block ready for shaping.

Stage 2: Forming the Continuous Strip

Once the billet is prepared, it must be converted into a long, thin strip. Two primary methods are used depending on the required profile and length.

Ram Extrusion Machines are ideal for creating specific cross-sectional profiles. The sintered PTFE billet is heated and forced through a shaped die, emerging as a continuous length of the desired shape. This method is efficient for standard profiles.

Skiving Machines are used to produce very long, thin sheets or strips from a cylindrical billet. The billet is rotated at high speed while a sharp blade "shaves" or skives off a continuous layer at a precisely controlled thickness, which can then be cut to the required width. This is excellent for creating long rolls of material.

Stage 3: Precision Finishing and Customization

The raw strip or extruded profile rarely meets the final required specifications. This is where precision machining creates the finished part.

CNC (Computer Numerical Control) Lathes are used for turning operations on cylindrical parts, such as creating precise outer and inner diameters on guide bands or rings.

CNC Milling Machines provide the ultimate flexibility for customization. They use rotating cutters to remove material and can create complex shapes, cut strips to exact lengths from a roll, machine intricate features, and ensure extremely tight tolerances on width.

The Foundation: Material and Quality Control

The machinery is only part of the equation. The quality of the final product is equally dependent on the raw material selection and the rigor of the quality management system.

Material Selection

The choice of material dictates the performance characteristics of the wear strip. Common options include:

- Virgin PTFE: Offers excellent chemical resistance and low friction but has lower wear resistance.

- Carbon Filled PTFE: Provides improved compressive strength and wear resistance.

- Bronze Filled PTFE: Offers the best wear resistance and high thermal conductivity, making it ideal for high-load applications.

Quality Management Systems

Reputable facilities operate under a certified ISO 9001:2015 quality management system. This ensures that procedures for material inspection, process control, and final product verification are strictly followed. Concepts like 5S and TQM (Total Quality Management) further drive continuous improvement in product consistency.

Understanding Production Capabilities and Limitations

While the manufacturing process is versatile, it is essential to understand its practical limits to ensure your design is manufacturable.

Custom vs. Standard Sizing

Facilities offer a range of standard sizes (e.g., 2.5 mm thickness in various widths) available in long rolls, often up to 25 meters. This is the most cost-effective option for common applications.

Custom sizes are readily achievable, with capabilities often reaching up to 50 mm in width and 5 mm in thickness. However, non-standard production runs are typically subject to minimum order quantities (MOQs) to justify the machine setup and material allocation.

Tolerances and Certification

Precision is a key benefit of this process. CNC machining allows for very strict tolerances on both thickness and width, which is critical for proper fit and function in hydraulic and pneumatic systems. Manufacturers should be able to provide complete product quality certifications to verify material and dimensional accuracy.

Making the Right Choice for Your Application

Use your understanding of the manufacturing process to specify the ideal component for your project.

- If your primary focus is cost-effectiveness for a standard application: Request standard-sized strips, which are typically available in rolls and benefit from efficient production methods like extrusion.

- If your primary focus is a unique shape or tight tolerance: Your design will rely on CNC milling capabilities, so be sure to provide detailed drawings and be prepared for potential minimum order quantities.

- If your primary focus is high performance under load or wear: Prioritize the material specification (e.g., Bronze Filled PTFE) just as much as the dimensions, as this choice is made at the very first stage of production.

By understanding how PTFE wear strips are made, you can better communicate your needs and ensure you receive a component that is perfectly suited for its purpose.

Summary Table:

| Stage | Key Equipment | Primary Function |

|---|---|---|

| 1. Billet Creation | Hydraulic Presses, Electric Ovens | Compress and sinter PTFE powder into a solid block |

| 2. Strip Forming | Ram Extrusion Machines, Skiving Machines | Shape the billet into a continuous strip or specific profile |

| 3. Finishing | CNC Lathes, CNC Milling Machines | Achieve final dimensions, tight tolerances, and custom features |

Need a high-performance PTFE wear strip or band?

KINTEK manufactures precision PTFE components—including seals, liners, labware, and custom wear strips—for the semiconductor, medical, laboratory, and industrial sectors. Our integrated production facilities handle everything from material selection and prototyping to high-volume orders, ensuring your parts meet exact dimensional and performance requirements.

Contact us today to discuss your project and receive a quote tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs