Teflon's value in electrical applications stems from a unique combination of exceptional insulating properties, high-temperature resistance, and chemical stability. Unlike many other plastics, Polytetrafluoroethylene (PTFE), the chemical name for Teflon, maintains its integrity under extreme electrical and environmental stress, making it an indispensable material for high-performance and critical systems.

The core reason for Teflon's value is not just that it's a good insulator, but that it is a stable and reliable insulator across a wide range of frequencies, temperatures, and harsh chemical environments where lesser materials would fail.

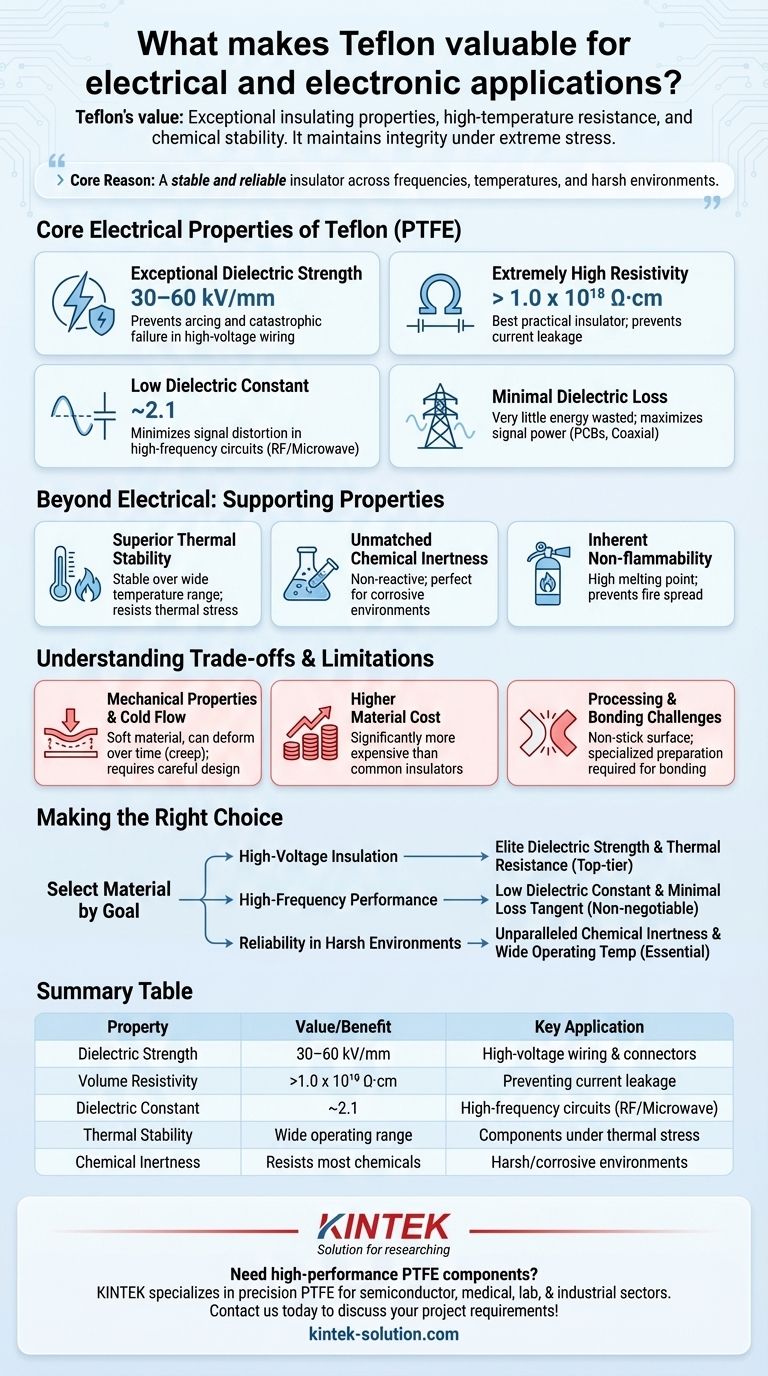

The Core Electrical Properties of Teflon (PTFE)

Teflon’s electrical performance is defined by several key metrics that work in concert to protect and enable electronic components.

Exceptional Dielectric Strength

Dielectric strength measures a material's ability to withstand a high voltage before it breaks down and allows current to pass through.

Teflon possesses a very high dielectric strength, typically in the range of 30–60 kV/mm. This makes it an ideal insulator for high-voltage wiring, cables, and connectors, preventing arcing and catastrophic failure.

Extremely High Resistivity

Resistivity indicates how strongly a material opposes the flow of electric current. A higher value means better insulation.

With a volume resistivity often exceeding 1.0 x 10¹⁸ Ω⋅cm, Teflon is one of the best practical insulators available. This property is crucial for preventing current leakage that could cause signal loss or safety hazards.

Low Dielectric Constant

The dielectric constant signifies a material's ability to store electrical energy in an electric field. For high-frequency applications, a lower value is better.

Teflon has a very low dielectric constant of approximately 2.1. This minimizes signal distortion and capacitive coupling, preserving signal integrity in high-frequency circuits, such as those used in RF, microwave, and data communications.

Minimal Dielectric Loss

The dielectric loss tangent measures how much signal energy is absorbed and dissipated as heat by the insulating material.

Teflon's extremely low loss factor means very little energy is wasted as it passes through. This ensures maximum signal power is transmitted, which is critical for efficient printed circuit boards (PCBs) and coaxial cables.

Beyond Electrical: The Supporting Properties

Teflon's utility is amplified by physical characteristics that allow it to perform in demanding operational conditions.

Superior Thermal Stability

Electrical components often generate significant heat. Teflon remains stable over a wide temperature range, making it suitable for applications where thermal stress would degrade other plastics.

Unmatched Chemical Inertness

Teflon is famously non-reactive and resists virtually all industrial chemicals and solvents. This makes it a perfect choice for insulating components used in corrosive environments, from factory floors to semiconductor manufacturing labs.

Inherent Non-flammability

Safety is a primary concern in electrical design. Teflon's high melting point and resistance to combustion help prevent the spread of fire in electrical systems, adding a critical layer of protection.

Understanding the Trade-offs and Limitations

While its properties are exceptional, Teflon is not the solution for every problem. An objective assessment requires understanding its limitations.

Mechanical Properties and Cold Flow

Teflon is a relatively soft material. Under sustained pressure, it can deform over time in a process known as "creep" or "cold flow." This must be accounted for in mechanical designs where tight tolerances are required.

Higher Material Cost

As a high-performance fluoropolymer, Teflon is significantly more expensive than common insulators like PVC or polyethylene. Its use is typically justified only when its unique performance characteristics are essential.

Processing and Bonding Challenges

Teflon's non-stick, inert surface makes it very difficult to bond to other materials using conventional adhesives. Specialized surface preparation techniques are required, adding complexity and cost to manufacturing processes.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary engineering goal.

- If your primary focus is high-voltage insulation: Teflon's elite dielectric strength and high thermal resistance make it a top-tier choice for preventing electrical breakdown.

- If your primary focus is high-frequency performance (RF/Microwave): Its low dielectric constant and minimal loss tangent are non-negotiable for maintaining signal integrity.

- If your primary focus is reliability in harsh environments: Its unparalleled chemical inertness and wide operating temperature range ensure components remain protected and functional.

By understanding these distinct properties, you can leverage Teflon not just as an insulator, but as a high-performance engineering solution for your most critical electrical and electronic systems.

Summary Table:

| Property | Value/Benefit | Key Application |

|---|---|---|

| Dielectric Strength | 30–60 kV/mm | High-voltage wiring & connectors |

| Volume Resistivity | >1.0 x 10¹⁸ Ω⋅cm | Preventing current leakage |

| Dielectric Constant | ~2.1 | High-frequency circuits (RF/Microwave) |

| Thermal Stability | Wide operating range | Components under thermal stress |

| Chemical Inertness | Resists most chemicals | Harsh/corrosive environments |

Need high-performance PTFE components for your critical systems?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We ensure your components meet the exacting standards required for superior electrical insulation, thermal stability, and chemical resistance.

Leverage our expertise in custom fabrication, from prototypes to high-volume orders, to solve your most challenging application needs. Contact us today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs