Teflon's suitability for bearings comes from its unique combination of an extremely low coefficient of friction, exceptional chemical resistance, and a very wide operational temperature range. This allows Polytetrafluoroethylene (PTFE), the chemical name for Teflon, to perform reliably in demanding environments where traditional lubricated bearings would quickly degrade or fail.

While Teflon's famous non-stick, low-friction surface is its primary advantage, its true value in bearing applications is its ability to maintain that performance under extreme chemical and thermal stress. This makes it a problem-solving material for systems where conventional lubrication is impossible or undesirable.

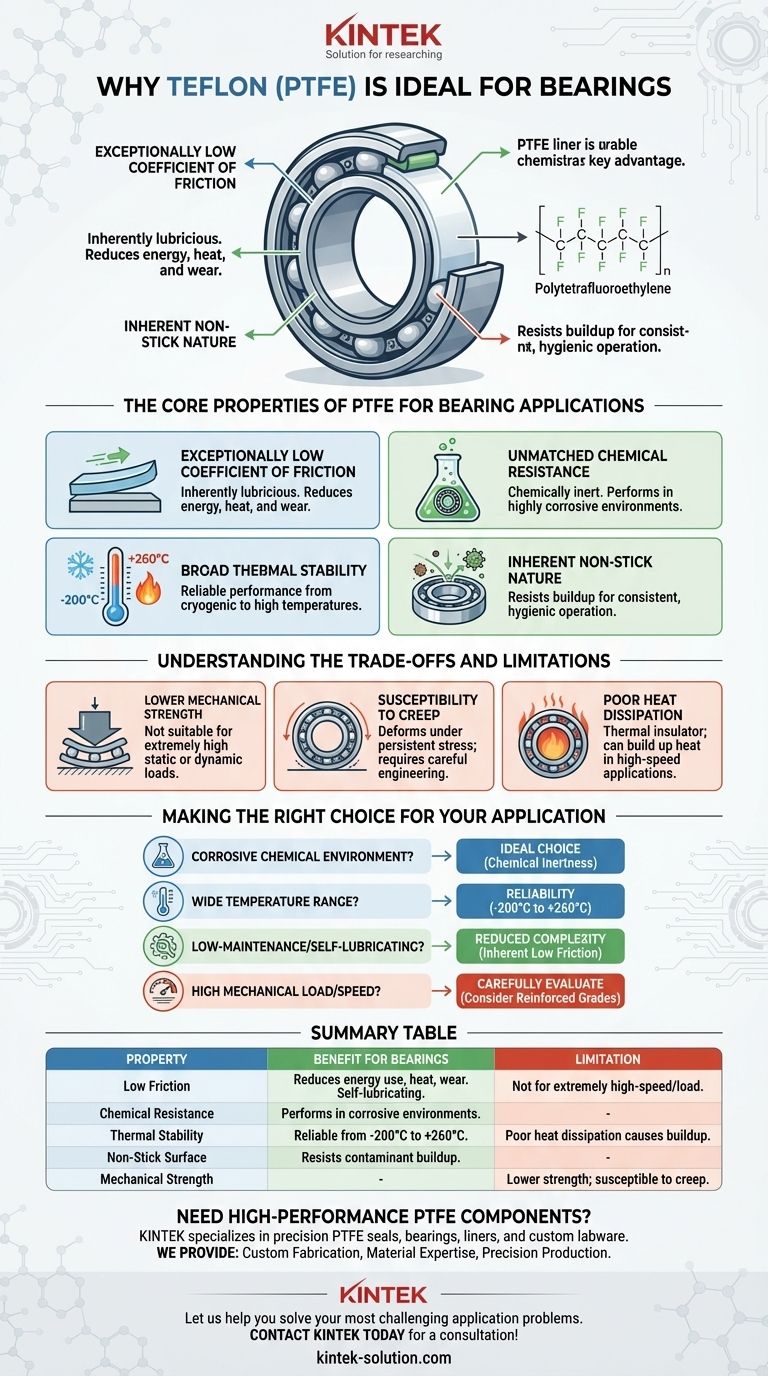

The Core Properties of PTFE for Bearing Applications

To understand why Teflon is so effective, we must look at the specific material properties that directly benefit motion-centric, high-wear components like bearings and bushings.

Exceptionally Low Coefficient of Friction

The most critical characteristic of Teflon for bearings is its extremely low friction. It has one of the lowest coefficients of friction of any solid material known.

This inherent lubricity directly reduces the energy required to move components, minimizes heat generation during operation, and significantly decreases wear and tear on moving parts.

Unmatched Chemical Resistance

Teflon is a chemically inert polymer, meaning it is non-reactive to the vast majority of industrial chemicals, acids, and solvents.

This allows Teflon bearings to be used in highly corrosive environments—such as chemical processing plants or medical equipment—without risk of material degradation or contamination.

Broad Thermal Stability

Teflon performs consistently across an exceptionally wide range of temperatures, typically from -200°C to +260°C (-328°F to +500°F).

This thermal stability makes it one of the few materials suitable for both cryogenic applications and high-temperature industrial processes, maintaining its structural integrity and low-friction properties at both extremes.

Inherent Non-Stick Nature

The same property that makes Teflon useful in cookware also benefits industrial applications. Its surface resists the buildup of contaminants, grime, or process materials.

This ensures a clean, consistent, and low-friction surface over the bearing's lifetime, which is especially valuable in industries like food production or medical device manufacturing where hygiene is critical.

Understanding the Trade-offs and Limitations

No material is perfect. While Teflon's properties are remarkable, a technical advisor must also highlight its limitations to ensure it is specified correctly.

Lower Mechanical Strength

Compared to metal bearings, Teflon has significantly lower compressive strength and hardness. It is a relatively soft material.

This makes pure Teflon bearings unsuitable for applications with extremely high static or dynamic loads, as the material can deform or "creep" under pressure.

Susceptibility to Creep

Creep is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress.

For designs with a constant, sustained load, the potential for creep in a Teflon bearing must be factored into the engineering calculations to avoid a loss of critical tolerances over time.

Poor Heat Dissipation

While Teflon can withstand high temperatures, it is a poor thermal conductor. It acts as an insulator, not a conductor.

In very high-speed applications, the heat generated by friction can build up within the bearing, as the material cannot dissipate it effectively. This can become a limiting factor for performance.

Making the Right Choice for Your Application

Selecting the correct bearing material requires matching its properties to the primary demands of your system.

- If your primary focus is a corrosive chemical environment: Teflon is an ideal choice due to its chemical inertness, preventing degradation where metals would fail.

- If your primary focus is a wide temperature range: Its stability from cryogenic levels to over 250°C provides reliability in extreme thermal conditions.

- If your primary focus is low-maintenance or self-lubricating systems: Teflon's inherent low friction eliminates the need for external lubricants, reducing complexity and contamination risk.

- If your primary focus is high mechanical load or speed: You must carefully evaluate Teflon's limitations and consider reinforced PTFE grades or alternative materials like bronze or steel.

Understanding these core properties and their associated trade-offs empowers you to specify the right material for your specific engineering challenge.

Summary Table:

| Property | Benefit for Bearings | Limitation |

|---|---|---|

| Low Friction | Reduces energy use, heat, and wear. Self-lubricating. | Not suitable for extremely high-speed/load applications. |

| Chemical Resistance | Performs in corrosive environments; ideal for chemical, medical, and food industries. | - |

| Thermal Stability | Reliable performance from -200°C to +260°C. | Poor heat dissipation can cause heat buildup. |

| Non-Stick Surface | Resists contaminant buildup for consistent performance. | - |

| Mechanical Strength | - | Lower compressive strength; susceptible to creep under sustained loads. |

Need high-performance PTFE components for your application?

KINTEK specializes in manufacturing precision PTFE seals, bearings, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance of properties needed for demanding environments.

We provide:

- Custom Fabrication: From prototypes to high-volume production.

- Material Expertise: Ensuring the right PTFE grade for your specific load, temperature, and chemical requirements.

- Precision Production: Reliable components that meet exact tolerances for optimal performance.

Let us help you solve your most challenging application problems. Contact KINTEK today for a consultation!

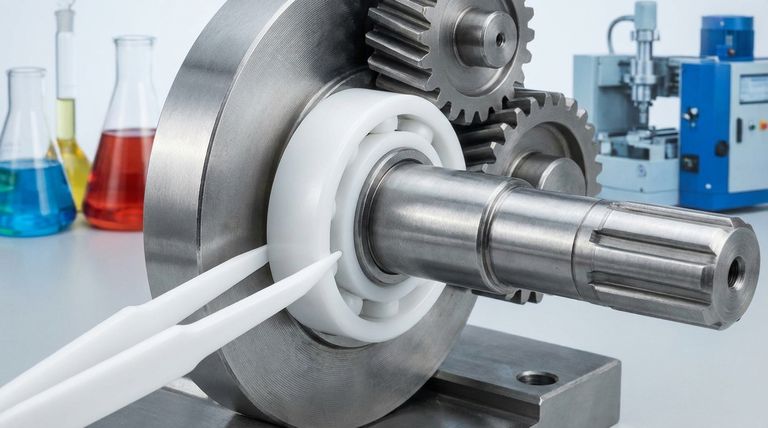

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What makes PTFE-lined diaphragm valves suitable for wastewater treatment? Ensure Reliability and Cost Savings

- What configurations are available for PTFE rotary shaft seals? Optimize Performance with Lip, Shell & Material Options

- In which industries or applications are PTFE O-rings typically used? Solve Extreme Sealing Challenges

- What are the installation methods for PTFE slide bearings? Bolting, Welding & Mortar Embedment

- What are the best practices for installing and maintaining PTFE expansion joints? Ensure Maximum Safety and Reliability

- What makes PTFE seals suitable for high-temperature applications? Unmatched Thermal & Chemical Stability

- How is PTFE utilized in the electrical and electronics industry? Unlock Superior Performance & Reliability

- Can you provide an example of PTFE expansion bellows improving safety in chemical plants? Real-World Case Study & Benefits