Teflon's suitability for electret manufacturing stems from its exceptional ability to permanently store an electrostatic charge. This unique capability is a direct result of its molecular structure, which provides an extremely high bulk resistivity and dielectric strength. These properties make Teflon a near-perfect electrical insulator that can trap and hold charges for extended periods, allowing it to function as the electrostatic equivalent of a permanent magnet.

An electret requires a material that can not only be implanted with an electric charge but also prevent that charge from leaking away. Teflon's combination of elite electrical insulation and robust physical stability makes it one of the best practical materials for creating and maintaining this permanent charge.

First, What is an Electret?

To understand why Teflon is so effective, we must first define the device it's used to create. An electret is a dielectric material that has a semi-permanent electric charge or dipole polarization.

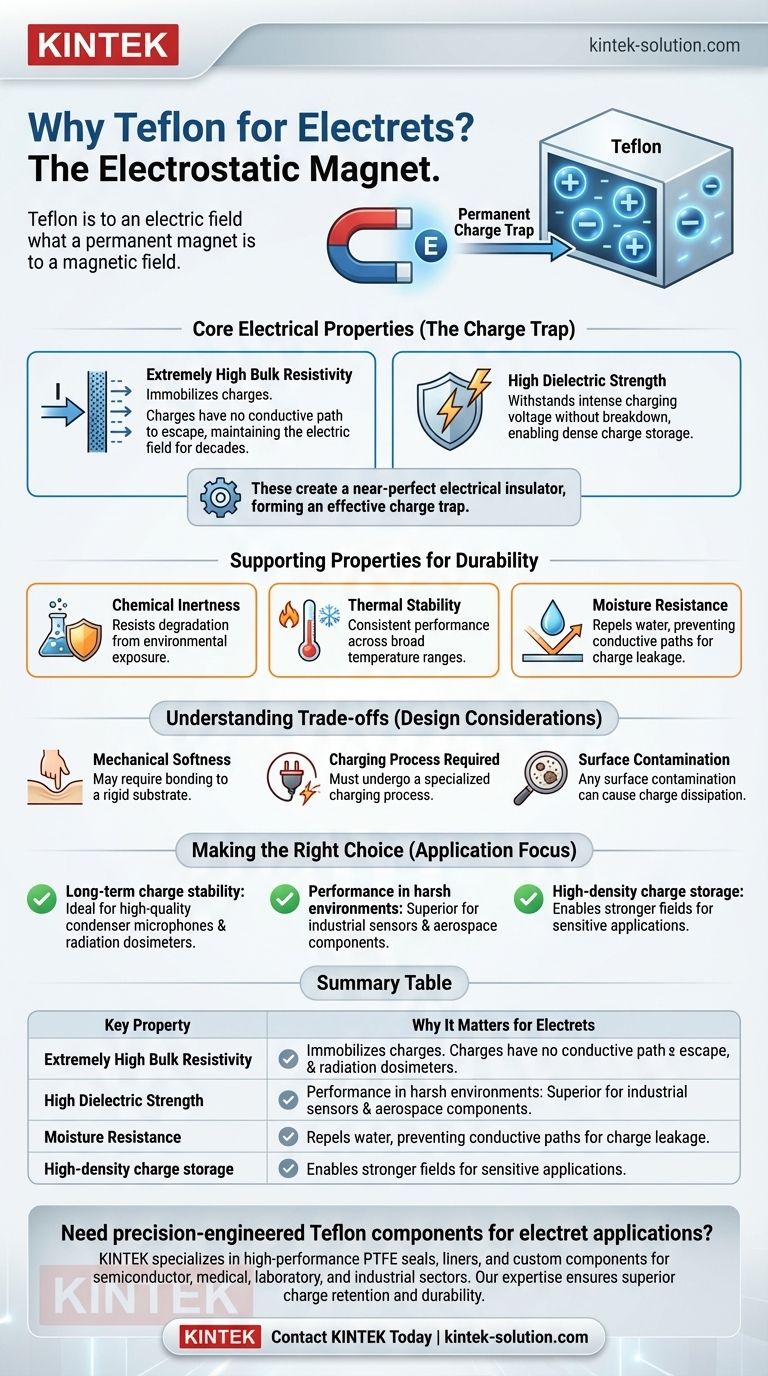

The Electrostatic Magnet

The simplest analogy is that an electret is to an electric field what a permanent magnet is to a magnetic field. While a magnet produces a persistent magnetic field, an electret produces a persistent external electric field.

The Need for a "Charge Trap"

This permanent field can only exist if the material is an exceptional electrical insulator. It must act as a "charge trap," holding the implanted electrical charges in place and preventing them from moving or dissipating over time. This is where the specific properties of a material like Teflon become critical.

The Core Electrical Properties of Teflon

Teflon is not just a good insulator; its electrical properties are extreme, making it uniquely qualified for electret applications.

Extremely High Bulk Resistivity

Bulk resistivity is the measure of how strongly a material opposes the flow of electric current. Teflon possesses one of the highest bulk resistivities of any known solid material.

Once charges are implanted into Teflon during the manufacturing process, this property effectively immobilizes them. The charges have no conductive path to escape, allowing the material to maintain its electric field for years or even decades.

High Dielectric Strength

Dielectric strength refers to the maximum electric field a material can withstand without "breaking down" and becoming conductive.

The process of creating an electret often involves exposing the material to a very high voltage to implant the charge. Teflon's high dielectric strength ensures it can endure this intense process without being damaged, allowing for a dense and stable charge to be embedded within it.

Key Supporting Properties

Beyond its primary electrical characteristics, Teflon's physical and chemical stability ensures the electret remains reliable over its entire operational life.

Chemical Inertness

Teflon is famously resistant to nearly all chemicals. This means an electret made from it will not degrade due to environmental exposure, preserving its delicate electrical properties.

Thermal Stability

As noted in material specifications, Teflon remains stable across a very broad temperature range. This ensures the performance of the electret is consistent and reliable, whether in hot or cold environments, preventing temperature fluctuations from causing premature charge decay.

Moisture Resistance

Teflon is hydrophobic, meaning it repels water. Moisture can provide a conductive path that would allow an electret's charge to leak away. Teflon’s resistance to water helps safeguard the stored charge and ensures long-term stability.

Understanding the Trade-offs

While exceptional, Teflon is not without limitations that must be considered in design and application.

Mechanical Softness

Teflon is a relatively soft polymer. For applications requiring high structural rigidity or abrasion resistance, a Teflon electret film often must be bonded to a more robust substrate or protected within a housing.

The Charging Process is Required

Teflon is not a "natural" electret; its properties only make it a perfect candidate. It must undergo a specialized manufacturing process, such as corona charging, to have the permanent electrostatic charge implanted within it.

Surface Contamination

Because the entire principle relies on perfect insulation, the surface of a Teflon electret must be kept impeccably clean. Any surface contamination can create a pathway for the stored charge to slowly dissipate, degrading performance.

Making the Right Choice for Your Application

Choosing Teflon is a decision based on the need for a stable, long-lasting electric field.

- If your primary focus is long-term charge stability: Teflon's unmatched bulk resistivity makes it the superior choice for applications needing a persistent electric field over many years, such as in high-quality condenser microphones and radiation dosimeters.

- If your primary focus is performance in harsh environments: Its exceptional chemical inertness and thermal stability ensure the electret will function reliably where other materials might fail, like in industrial sensors or aerospace components.

- If your primary focus is high-density charge storage: Teflon's high dielectric strength allows it to be charged to a greater degree without breaking down, resulting in a stronger external electric field for more sensitive applications.

Ultimately, Teflon's unique combination of near-perfect electrical insulation and extreme physical durability makes it the definitive material for creating reliable, long-lasting electrets.

Summary Table:

| Key Property | Why It Matters for Electrets |

|---|---|

| Extremely High Bulk Resistivity | Traps and immobilizes charges, preventing leakage for years or decades. |

| High Dielectric Strength | Withstands intense charging processes without breakdown, enabling dense charge storage. |

| Chemical Inertness & Thermal Stability | Ensures reliability in harsh environments, from industrial sensors to aerospace components. |

| Moisture Resistance | Repels water, safeguarding the electret's charge from conductive paths that cause decay. |

Need precision-engineered Teflon components for your electret applications?

At KINTEK, we specialize in manufacturing high-performance PTFE (Teflon) seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production ensures your electrets benefit from Teflon's superior charge retention and durability—whether you need prototypes or high-volume orders.

Contact us today to discuss how our custom PTFE solutions can enhance the stability and longevity of your electret-based devices!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What makes Teflon suitable for low-friction applications? Unlock Superior Performance with Low-Friction PTFE

- How was Teflon historically used in armor-piercing bullets? Debunking the 'Cop-Killer' Myth

- What is the difference between virgin PTFE and filled PTFE? Choose the Right Material for Your Application

- What is the molecular structure of PTFE? The Key to Its Unmatched Chemical & Thermal Resistance

- What is the dissipation factor of PTFE? A Guide to Virgin vs. Filled Grades

- How does PTFE laminated fabric enhance sportswear? Achieve Ultimate Comfort & Performance

- What are the benefits of glass-filled PTFE? Achieve Superior Strength & Wear Resistance

- What are some consumer product applications of PTFE? Discover its Versatility Beyond Non-Stick Pans