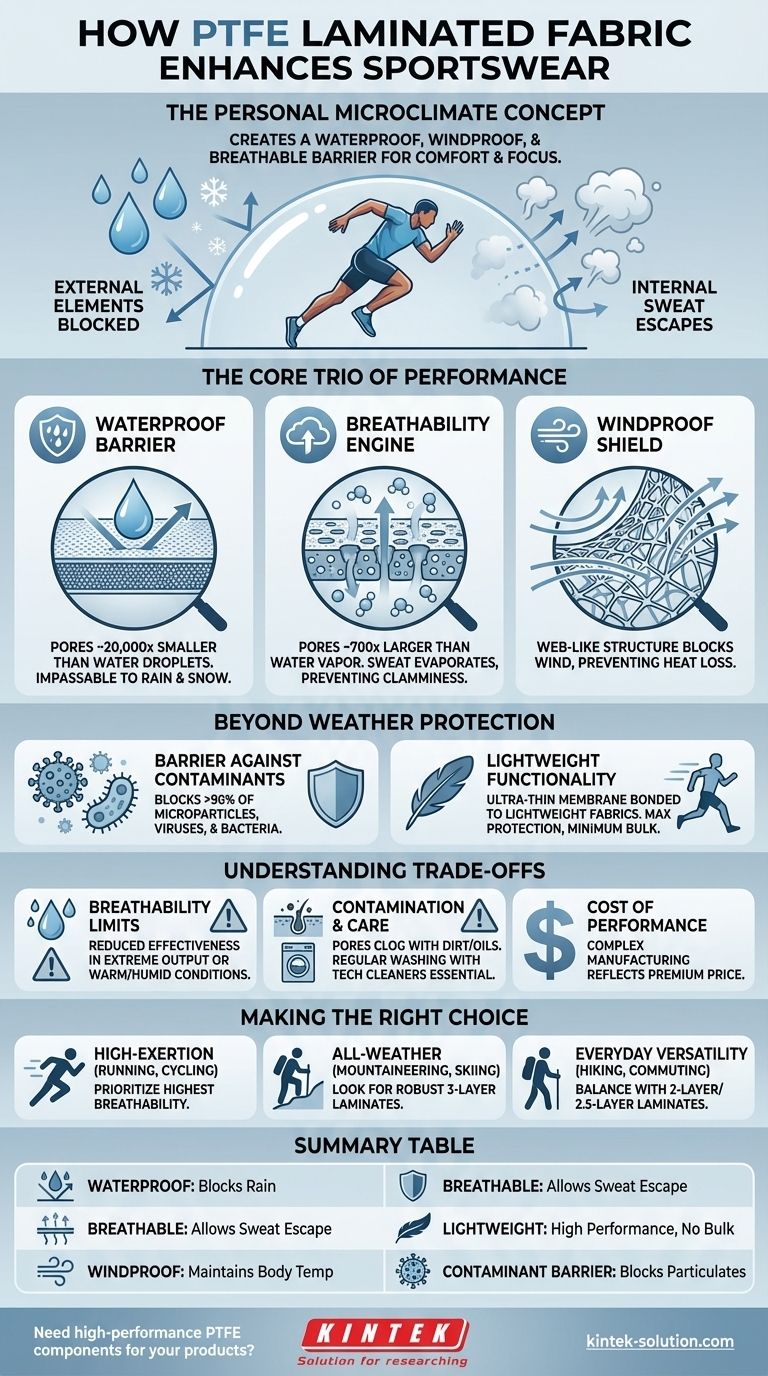

At its core, PTFE laminated fabric transforms sportswear by solving a fundamental conflict for any active person: staying dry from external rain while simultaneously allowing internal sweat to escape. This material creates a personal microclimate, providing a waterproof, windproof, and breathable barrier that keeps you comfortable and focused, regardless of the weather or your level of exertion.

The essential advantage of PTFE laminated fabric lies in its microporous structure. Billions of pores per square inch are too small for water droplets to penetrate from the outside, yet large enough for water vapor (sweat) to escape from the inside, delivering elite performance in a single lightweight material.

The Core Trio of Performance

The value of PTFE fabric in sportswear comes down to its ability to master three critical functions simultaneously.

The Waterproof Barrier

The PTFE membrane is engineered with pores approximately 20,000 times smaller than a water droplet.

This structure creates an impassable physical barrier, ensuring that rain, snow, and moisture from the environment cannot penetrate the fabric, keeping you completely dry.

The Breathability Engine

While blocking liquid water, the pores in the PTFE membrane are about 700 times larger than a water vapor molecule.

This crucial difference allows perspiration vapor to pass directly through the fabric and evaporate. This process prevents the clammy, uncomfortable feeling that occurs when sweat gets trapped against your skin, a common failure of non-breathable waterproof materials.

The Windproof Shield

The complex, web-like structure of the PTFE membrane effectively blocks wind from passing through the garment.

By preventing this convective heat loss, the fabric helps you maintain a stable body temperature, keeping you warmer and more comfortable in harsh, windy conditions.

Beyond Weather Protection

While the waterproof-breathable combination is its primary benefit, PTFE lamination offers other valuable properties.

Barrier Against Contaminants

The extremely small pore size provides a high microparticle barrier rate, often exceeding 90%.

This means the fabric can effectively block not only water but also viruses, bacteria, and other environmental particulates from reaching your skin.

Lightweight Functionality

Advanced lamination techniques bond the ultra-thin PTFE membrane to durable yet lightweight face fabrics.

This results in high-performance gear that offers maximum protection without the weight or bulk of traditional weather-resistant materials, improving mobility and reducing fatigue.

Understanding the Trade-offs

No material is perfect. Understanding the limitations of PTFE laminates is key to using them effectively.

Breathability Has Limits

During extreme, high-output aerobic activity, you may produce sweat vapor faster than any fabric can transport it. In very warm or humid conditions, the effectiveness of breathability is naturally reduced.

Contamination and Care

The microscopic pores can become clogged by dirt, body oils, or detergent residue, which severely impacts the fabric's breathability.

Proper and regular washing with specialized technical cleaners is essential to maintain the performance of the garment over its lifespan.

The Cost of Performance

PTFE lamination is a complex and advanced manufacturing process. This technology represents the premium end of the market, which is reflected in the higher cost of the final product.

Making the Right Choice for Your Activity

To select the best gear, match the fabric's properties to your primary goal.

- If your primary focus is high-exertion activity (trail running, cycling): Prioritize garments that advertise the highest breathability ratings to manage intense sweat output effectively.

- If your primary focus is all-weather protection (mountaineering, skiing): Look for more robust 3-layer PTFE laminates that offer maximum durability, waterproofing, and wind resistance for harsh conditions.

- If your primary focus is everyday versatility (hiking, commuting): A 2-layer or 2.5-layer PTFE laminate provides an excellent balance of waterproof performance, breathability, and packable convenience.

By understanding this technology, you can select apparel that works as hard as you do, allowing you to perform at your best.

Summary Table:

| Property | Benefit |

|---|---|

| Waterproof | Blocks external rain and moisture with a microporous barrier. |

| Breathable | Allows sweat vapor to escape, preventing clamminess. |

| Windproof | Blocks wind to maintain body temperature. |

| Lightweight | Provides high performance without bulk or weight. |

| Contaminant Barrier | Blocks viruses, bacteria, and particulates. |

Need high-performance PTFE components for your products?

KINTEK specializes in the precision manufacturing of PTFE components—including custom seals, liners, and labware—for the medical, semiconductor, laboratory, and industrial sectors. Our expertise in advanced materials like PTFE ensures your products deliver superior performance, durability, and reliability.

Whether you require prototypes or high-volume production, we can fabricate a solution tailored to your exact needs.

Contact our experts today to discuss how we can enhance your next project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts