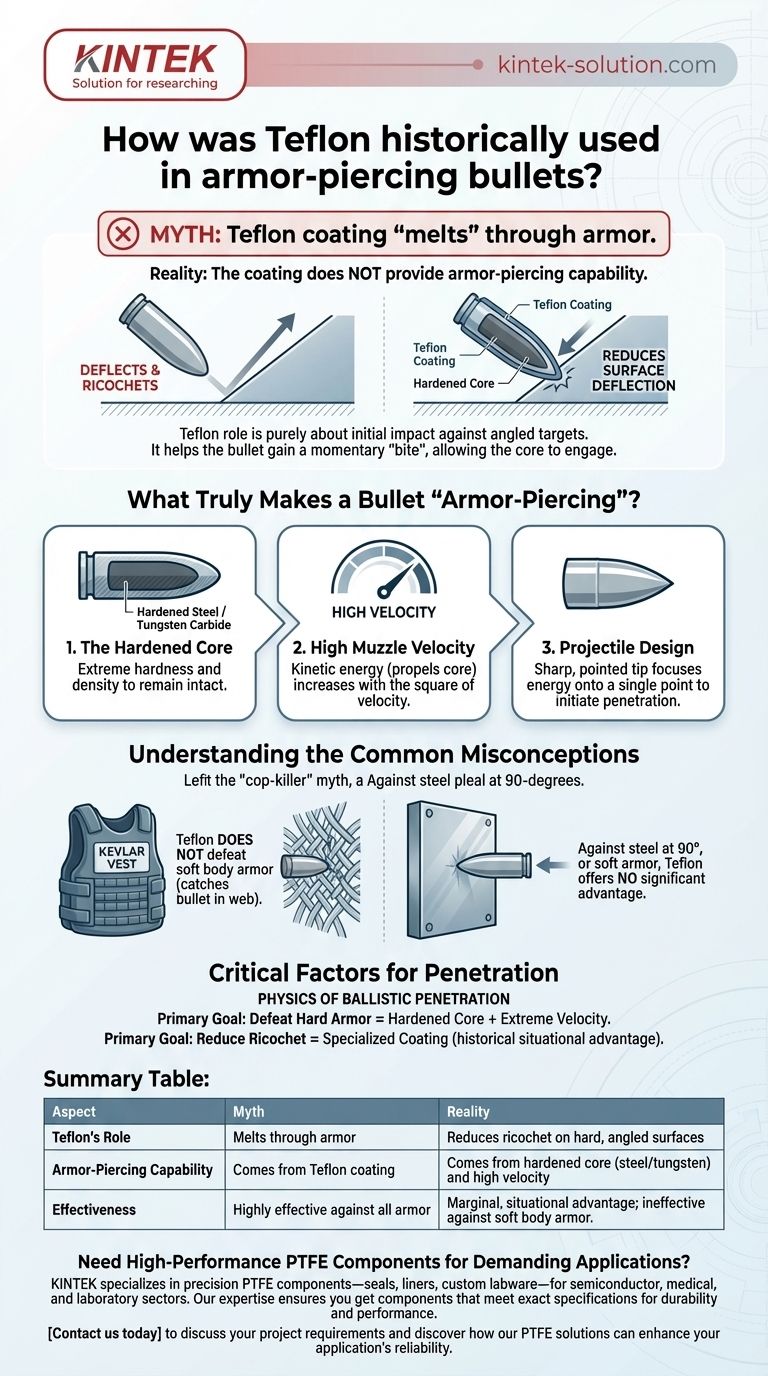

Historically, Teflon was used on certain bullets not to "melt" through armor, but for a much more subtle and specific purpose. First developed in the 1960s, the Teflon coating was designed to reduce a bullet's tendency to deflect or ricochet when striking a hard, angled surface like a car door or windshield. This allowed the bullet's core to make better contact and begin the work of penetration.

The central misunderstanding is that the Teflon coating itself provides armor-piercing capability. In reality, a bullet's ability to defeat armor is determined almost entirely by the hardness of its core and its velocity, not by a thin polymer layer.

The Actual Purpose of the Teflon Coating

The role of Teflon on a bullet is purely about the initial moment of impact, particularly against angled targets. It does not contribute to the penetration itself.

Reducing Surface Deflection

When a standard bullet strikes a hard, angled surface, it often glances off without delivering its full energy to the target.

The Teflon coating, being relatively soft, helps the bullet gain a momentary "bite" on the surface instead of skipping away.

Aiding the Penetrator Core

This improved contact allows the bullet's hardened inner core to engage with the target material directly. The coating's job is over in the first microsecond of impact.

It is a facilitator, not the primary actor. Its goal is simply to ensure the bullet's energy is transferred into the target rather than away from it.

What Truly Makes a Bullet "Armor-Piercing"?

The term "armor-piercing" refers to ammunition specifically designed to defeat hardened materials like steel plate. This capability comes from three key factors that have nothing to do with a surface coating.

1. The Hardened Core

True armor-piercing rounds use a core made of an extremely hard and dense material, such as hardened steel or tungsten carbide.

This dense core has the mass and structural integrity to remain intact while punching through a target that would shatter a conventional lead-core bullet.

2. High Muzzle Velocity

The hardened core must be propelled at extremely high speeds. Kinetic energy, which is what allows the bullet to do work on the target, increases with the square of its velocity.

High velocity is the engine that drives the hardened core through the armor.

3. Projectile Design

Armor-piercing projectiles are typically shaped with a sharp, pointed tip. This design focuses all the bullet's immense energy onto a single, minuscule point, maximizing pressure and initiating the penetration process.

Understanding the Common Misconceptions

The myth surrounding Teflon-coated bullets arose from a fundamental misunderstanding of their function, leading to them being incorrectly labeled "cop-killer" bullets in the media.

The Myth of "Melting" Through Armor

The popular but false narrative was that the low-friction Teflon would "melt" its way through a protective vest. This is physically incorrect.

Soft body armor, made of materials like Kevlar, functions by "catching" a bullet in a strong woven web. A slippery coating does not defeat this mechanism.

Marginal Performance Gain

The advantage offered by the coating is slight and situational. It is most relevant against angled, thin, hard targets.

Against a steel plate hit at a 90-degree angle, or against soft body armor, the Teflon coating provides no significant advantage.

The Critical Factors for Penetration

To distinguish fact from fiction, it's essential to focus on the principles of physics that govern ballistic penetration.

- If the primary goal is to defeat hard armor: The non-negotiable requirements are a dense, hardened penetrator core and extremely high velocity.

- If the primary goal is to reduce ricochet on angled surfaces: A specialized coating was historically used to offer a slight advantage, but it cannot compensate for an inadequate core or low velocity.

Ultimately, effective ballistic penetration is a matter of materials science and kinetic energy, not a superficial coating.

Summary Table:

| Aspect | Myth | Reality |

|---|---|---|

| Teflon's Role | Melts through armor like a "cop-killer" bullet. | Reduces ricochet on hard, angled surfaces (e.g., car doors). |

| Armor-Piercing Capability | Comes from the Teflon coating. | Comes from a hardened core (steel/tungsten) and high velocity. |

| Effectiveness | Highly effective against all armor. | Marginal, situational advantage; ineffective against soft body armor. |

Need High-Performance PTFE Components for Demanding Applications?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for industries where material integrity is critical, such as semiconductor, medical, and laboratory sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get components that meet your exact specifications for durability and performance.

Contact us today to discuss your project requirements and discover how our PTFE solutions can enhance your application's reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs