At its core, Teflon's suitability for low-friction applications stems from its molecular structure, which gives it one of the lowest coefficients of friction of any known solid. This unique property, a result of strong carbon-fluorine bonds, allows other materials to glide over its surface with minimal resistance, dramatically reducing wear and energy loss.

The key takeaway is not just Teflon's inherent slipperiness, but its powerful combination of low friction with exceptional chemical inertness, high-temperature resistance, and durability. This synergy makes it a reliable solution for demanding engineering challenges where other materials would fail.

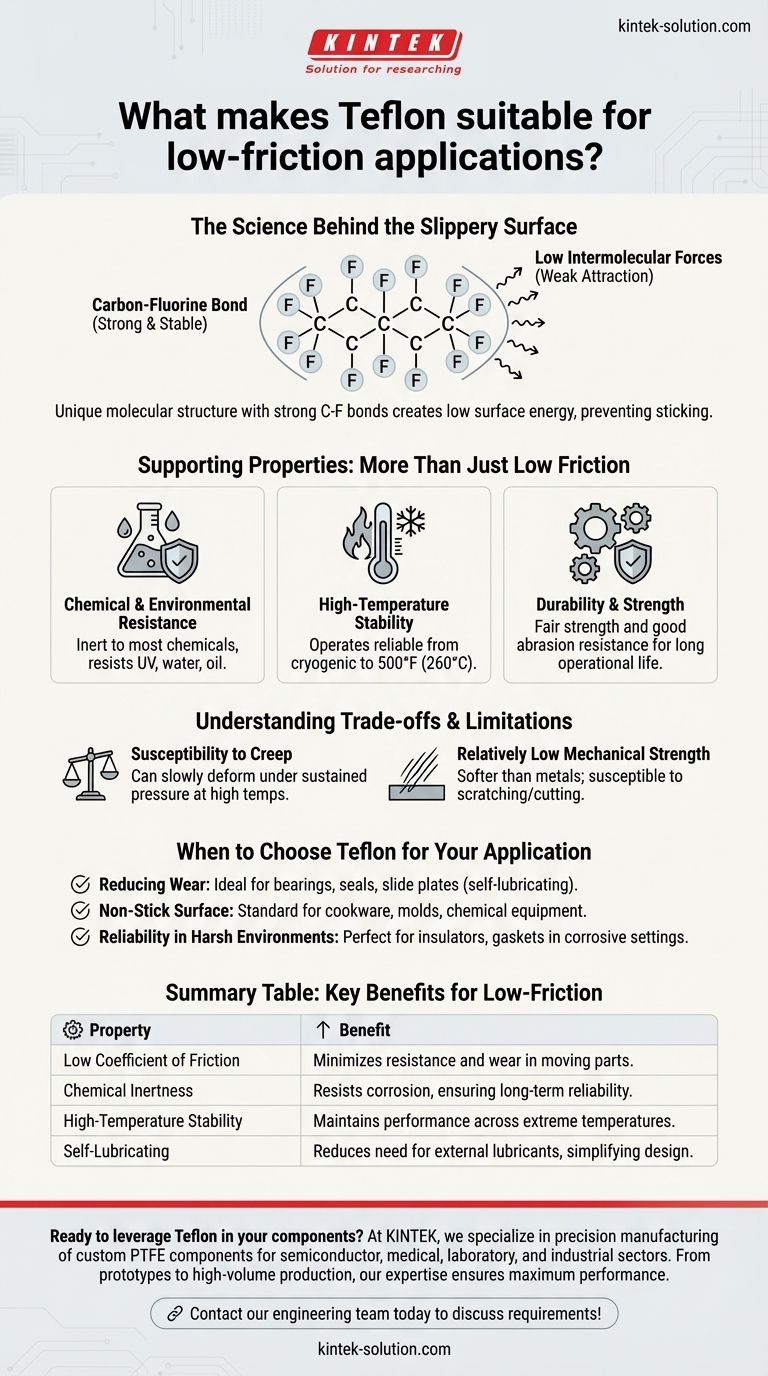

The Science Behind the Slippery Surface

The reason for Teflon's famous non-stick quality is found at the molecular level. It's a result of the unique way its atoms are bonded together.

The Carbon-Fluorine Bond

Polytetrafluoroethylene (PTFE), the chemical name for Teflon, consists of a long chain of carbon atoms completely surrounded by fluorine atoms. The bond between carbon and fluorine is exceptionally strong and stable.

Low Intermolecular Forces

These fluorine atoms effectively shield the carbon backbone, creating a surface with very low surface energy. This means there are very weak forces of attraction between Teflon molecules and the molecules of any other substance, preventing things from sticking to it.

More Than Just Low Friction: The Supporting Properties

While its low friction is the headline feature, several other properties are critical for its performance in real-world applications.

Chemical and Environmental Resistance

Teflon is almost completely inert, meaning it does not react with the vast majority of chemicals. It also has excellent weatherability, resisting degradation from UV light, water, and oil.

High-Temperature Stability

This material can operate reliably across a wide range of temperatures. Its resistance to heat makes it suitable for applications from non-stick cookware to industrial components exposed to high-heat processes.

Durability and Strength

For a polymer, Teflon possesses fair strength and good abrasion resistance. This ensures that components like bearings and seals not only reduce friction but also have a long operational life.

Understanding the Trade-offs

No material is perfect, and an objective assessment requires understanding Teflon's limitations.

Susceptibility to Creep

Under sustained pressure, especially at elevated temperatures, PTFE can slowly deform. This phenomenon, known as "creep" or "cold flow," must be accounted for in high-load structural designs.

Relatively Low Mechanical Strength

Compared to metals or high-performance engineering plastics, Teflon is relatively soft. It has lower tensile strength and can be more susceptible to scratching or cutting by sharp contaminants.

When to Choose Teflon for Your Application

Selecting the right material depends entirely on the primary goal of your project.

- If your primary focus is reducing wear in moving parts: Teflon is an ideal choice for bearings, seals, and slide plates due to its self-lubricating nature.

- If your primary focus is a non-stick surface: Its low surface energy makes it the standard for cookware, industrial molds, and chemical processing equipment.

- If your primary focus is reliability in harsh environments: The combination of chemical inertness, weatherability, and thermal stability makes it perfect for outdoor electrical insulators and gaskets in corrosive settings.

Understanding this blend of properties empowers you to deploy Teflon where it can provide the most significant and lasting value.

Summary Table:

| Property | Benefit for Low-Friction Applications |

|---|---|

| Low Coefficient of Friction | Minimizes resistance and wear in moving parts like bearings and seals. |

| Chemical Inertness | Resists corrosion from harsh chemicals, ensuring long-term reliability. |

| High-Temperature Stability | Maintains performance in environments from cryogenic to 500°F (260°C). |

| Self-Lubricating | Reduces or eliminates the need for external lubricants, simplifying design. |

Ready to leverage Teflon's low-friction properties in your components?

At KINTEK, we specialize in precision manufacturing of custom PTFE components—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or high-volume production, our expertise ensures your parts deliver maximum performance and durability.

Contact our engineering team today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments