In short, Polytetrafluoroethylene (PTFE) is uniquely suitable for chemical and pharmaceutical industries because of its profound chemical inertness, non-contaminating nature, and superior sealing capabilities. This combination of properties ensures that it can withstand aggressive chemicals without degrading, while also protecting the purity of the sensitive products it comes into contact with.

The core reason for PTFE's dominance is its principle of non-interaction. It does not react with, contaminate, or absorb the substances it handles, ensuring that both the equipment and the end-product maintain their integrity, a non-negotiable requirement in these highly regulated fields.

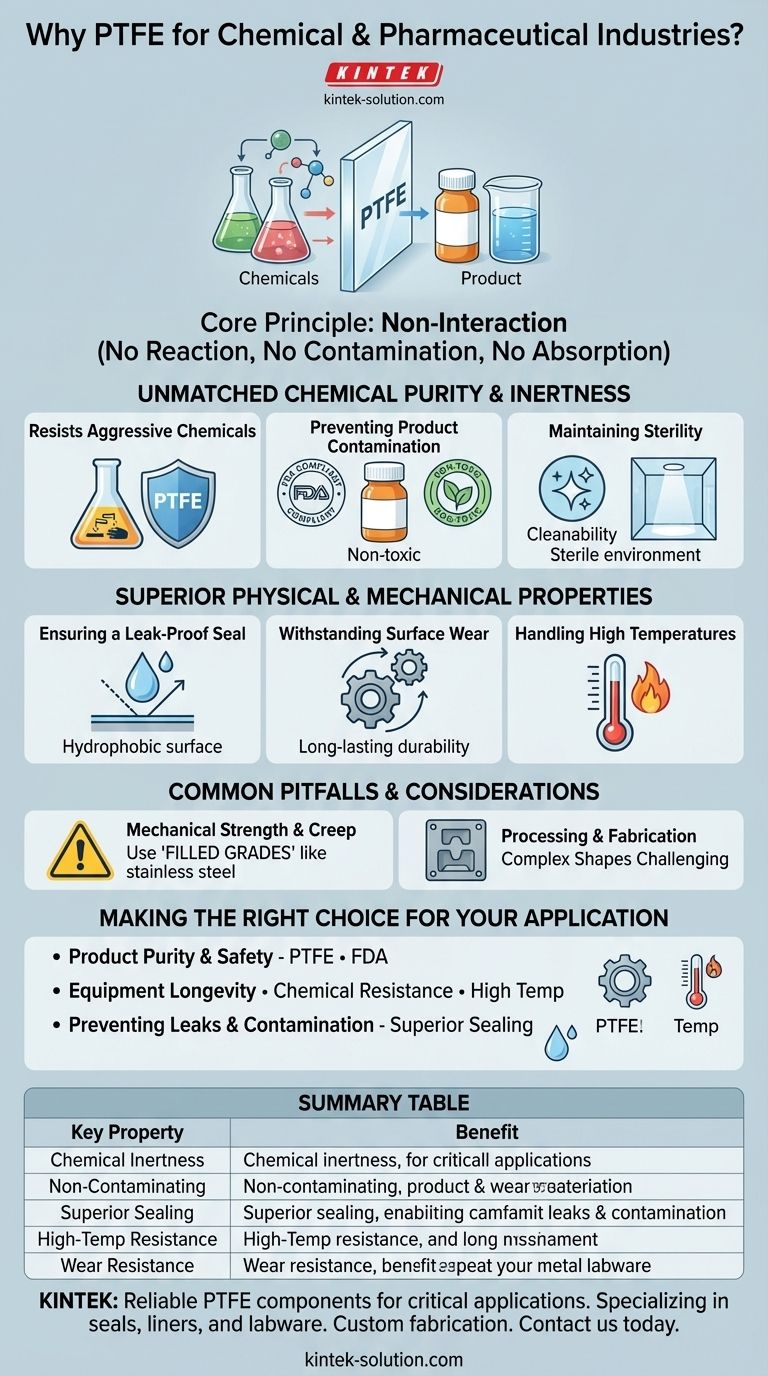

The Foundation: Unmatched Chemical Purity and Inertness

The primary value of PTFE in sensitive applications is its ability to remain completely unaffected by its environment. This chemical indifference is the bedrock of its utility.

### Resisting Aggressive Chemicals

PTFE is almost universally non-reactive. It resists corrosion from a wide range of harsh chemicals, including potent acids and bases.

This inertness means components like seals, gaskets, and valve liners will not degrade or fail when exposed to aggressive manufacturing or cleaning agents, ensuring long-lasting performance.

### Preventing Product Contamination

In pharmaceutical and food applications, product purity is paramount. PTFE is non-toxic and non-contaminating.

It does not leach chemicals or compromise the safety of drugs or other products. Because of this, PTFE complies with stringent FDA standards, making it a trusted material for direct-contact applications.

### Maintaining Sterility

PTFE's surface is resistant to bacterial growth and is easy to clean and sterilize.

This property is critical for maintaining strict hygiene standards in pharmaceutical manufacturing, where it can endure sterilization processes without reacting with cleaning agents or degrading.

Superior Physical and Mechanical Properties

Beyond its chemical nature, PTFE's physical characteristics make it an exceptional material for sealing and guiding applications.

### Ensuring a Leak-Proof Seal

A key physical property of PTFE is that it is non-wetting. This means liquids bead up on its surface rather than spreading out.

This hydrophobic nature contributes to its superior sealing capabilities, creating a more effective barrier against leaks and preventing the ingress of contaminants.

### Withstanding Surface Wear

In manufacturing equipment, components are often subjected to constant movement and friction.

PTFE gaskets and guide strips are highly durable and can withstand significant surface wear and tear, which is essential during repetitive processes like drug manufacturing.

### Handling High Temperatures

Many chemical and pharmaceutical processes involve high temperatures. PTFE components maintain their structural integrity and performance characteristics even when exposed to elevated temperatures.

Common Pitfalls and Considerations

While PTFE is an exceptional material, its selection requires an understanding of its limitations to avoid misapplication.

### Mechanical Strength

Standard PTFE is a relatively soft material. In high-pressure or high-load applications, it can be susceptible to "creep" or cold flow.

To counteract this, filled grades of PTFE are used. For example, stainless steel-filled PTFE combines the inertness of PTFE with the durability and strength of steel, making it ideal for more demanding applications.

### Processing and Fabrication

PTFE cannot be melt-processed like common plastics, which can make manufacturing complex shapes more challenging and costly. This is a design consideration that should be addressed early in the component selection process.

Making the Right Choice for Your Application

Selecting the right material comes down to your primary operational driver.

- If your primary focus is product purity and safety: PTFE's non-toxic, non-contaminating, and FDA-compliant nature makes it the definitive choice.

- If your primary focus is equipment longevity: Its resistance to corrosive chemicals and high temperatures ensures a longer operational life for critical components.

- If your primary focus is preventing leaks and contamination: The superior, non-wetting sealing properties of PTFE provide a reliable barrier you can trust.

Ultimately, selecting PTFE is a decision for uncompromising safety and performance where material failure is not an option.

Summary Table:

| Key Property | Benefit in Chemical/Pharma Industries |

|---|---|

| Chemical Inertness | Resists corrosion from acids, bases, and aggressive chemicals, ensuring equipment longevity. |

| Non-Contaminating | Non-toxic, FDA-compliant, and prevents product contamination, critical for drug purity. |

| Superior Sealing | Hydrophobic, non-wetting surface creates leak-proof barriers and maintains sterility. |

| High-Temp Resistance | Maintains integrity in elevated temperature processes common in manufacturing. |

| Wear Resistance | Durable against friction and repetitive use in equipment like gaskets and guide strips. |

Need reliable PTFE components for your critical applications? KINTEK specializes in manufacturing high-precision PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring your equipment meets the highest standards of purity and performance. Contact us today to discuss your specific requirements and leverage our expertise in material science for your industry.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- What industrial applications does PTFE have? Unlock Performance in Extreme Environments

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE