To put it simply, PTFE slide bearings achieve their space and weight efficiency by replacing complex, bulky mechanical assemblies with a simple, layered material pad. Their design relies on the exceptionally low friction of Polytetrafluoroethylene (PTFE) to manage movement, eliminating the need for the heavy rollers, pins, and rocker arms found in traditional bearings. This fundamental shift from mechanical systems to material science results in a dramatically smaller and lighter component.

The core reason for PTFE's efficiency is that its inherent material properties—specifically its self-lubricating nature and extremely low friction—allow for a minimalist design that handles immense loads and movement within a compact, maintenance-free footprint.

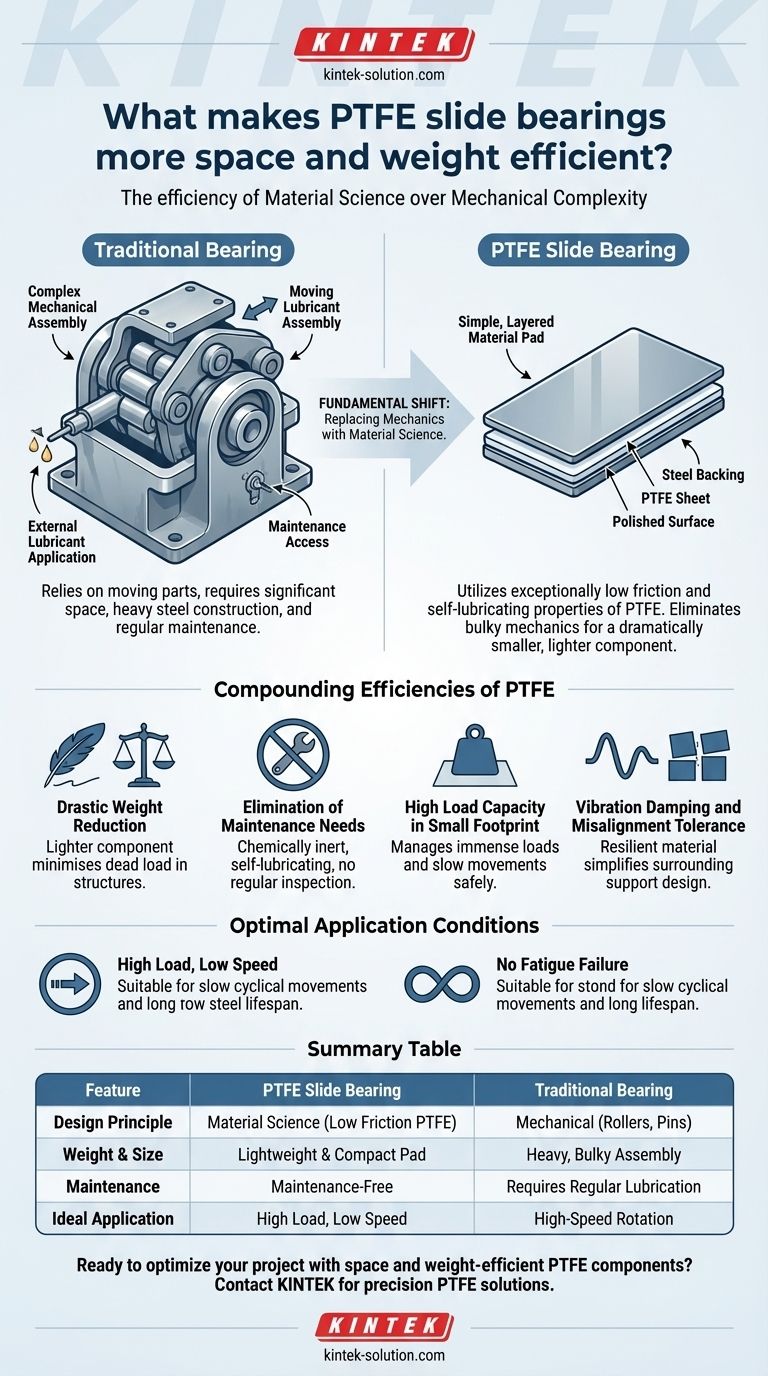

The Core Principle: Replacing Mechanics with Material Science

The efficiency advantage of a PTFE slide bearing isn't an incremental improvement; it's the result of a fundamentally different approach to managing structural loads and movement.

The Challenge of Traditional Bearings

Traditional roller bearings and rocker arm supports are essentially mechanical machines. They depend on moving parts like cylinders and pins to accommodate thermal expansion, contraction, and other structural shifts.

These mechanical components require significant physical space and are constructed from heavy steel, which adds considerable weight and complexity to the overall structure.

The Simplicity of the PTFE Pad

A PTFE slide bearing discards this mechanical complexity. Its design is a simple, layered composite, typically involving a steel backing plate and a sheet of PTFE that slides against a polished stainless steel surface.

This entire assembly is flat and compact. It bears load directly through the materials themselves rather than through an intricate mechanism.

How Material Properties Eliminate Bulk

The key is PTFE's uniquely low coefficient of friction, the lowest of any solid material. This property allows surfaces to slide against each other smoothly under immense pressure without seizing.

Because the material is self-lubricating, there is no need for external lubricants, grease fittings, or the systems required to apply them. This material-level function replaces the physical action of a roller, leading to a much smaller and lighter design.

The Compounding Efficiencies of PTFE

The initial benefit of a compact design creates a cascade of related advantages that further enhance a project's overall efficiency.

Drastic Weight Reduction

By replacing heavy steel rollers and rocker assemblies with a simple layered pad, the weight of the bearing component itself is significantly reduced. This is critical in large structures like bridges where minimizing dead load is a primary engineering goal.

Elimination of Maintenance Needs

PTFE is chemically inert and highly resistant to weathering and dirt. Combined with its self-lubricating properties, this makes the bearing virtually maintenance-free.

Traditional bearings require regular inspection and lubrication, which demands safe access space and adds to the long-term operational footprint of the structure. PTFE bearings eliminate this requirement.

High Load Capacity in a Small Footprint

PTFE slide bearings perform exceptionally well under high loads and low speeds. This means a relatively small bearing pad can safely manage the immense forces and slow movements characteristic of large-scale civil engineering projects.

Vibration Damping and Misalignment Tolerance

The material itself provides a degree of vibration damping and can tolerate minor misalignments without failing. This resilience simplifies the design and construction of the surrounding support structures, contributing to overall project efficiency.

Understanding the Trade-offs

While highly efficient, PTFE slide bearings are engineered for a specific set of conditions. Understanding their ideal application is key to leveraging their advantages.

Optimal Conditions: High Load, Low Speed

The self-lubricating and low-friction properties of PTFE are most effective under high compressive loads and the slow, cyclical movements caused by thermal changes or gradual load shifts. They are not designed for high-speed rotational applications.

No Fatigue Failure

Because they do not rely on moving mechanical parts, PTFE bearings are not subject to the kind of fatigue failure that can affect rollers or pins over millions of cycles. Their lifespan is primarily determined by the durability of the materials themselves, which are exceptionally long-lasting.

Making the Right Choice for Your Project

Selecting the correct bearing type depends entirely on your project's primary constraints and long-term goals.

- If your primary focus is minimizing structural weight and footprint: PTFE slide bearings are the superior choice due to their compact, lightweight, and simple design.

- If your primary focus is reducing long-term operational costs: The maintenance-free nature of PTFE bearings eliminates inspection and lubrication costs, making them highly efficient over the structure's lifespan.

- If your primary focus is design simplicity and structural resilience: PTFE's ability to tolerate misalignment and dampen vibration can simplify the engineering of the overall support system.

By leveraging advanced material science, PTFE bearings offer a more elegant and efficient solution for managing the forces at play in modern structures.

Summary Table:

| Feature | PTFE Slide Bearing | Traditional Bearing |

|---|---|---|

| Design Principle | Material Science (Low Friction PTFE) | Mechanical (Rollers, Pins) |

| Weight & Size | Lightweight, Compact Pad | Heavy, Bulky Assembly |

| Maintenance | Maintenance-Free | Requires Regular Lubrication |

| Ideal Application | High Load, Low Speed (e.g., Bridges) | High-Speed Rotation |

Ready to optimize your project with space and weight-efficient PTFE components?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom slide bearings, seals, liners, and labware. Our expertise is trusted by engineers in the semiconductor, medical, laboratory, and industrial sectors to deliver solutions that reduce weight, simplify design, and eliminate long-term maintenance.

Whether you need a prototype or a high-volume order, we can fabricate the perfect PTFE component for your application.

Contact us today to discuss how our PTFE solutions can bring efficiency and reliability to your project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments