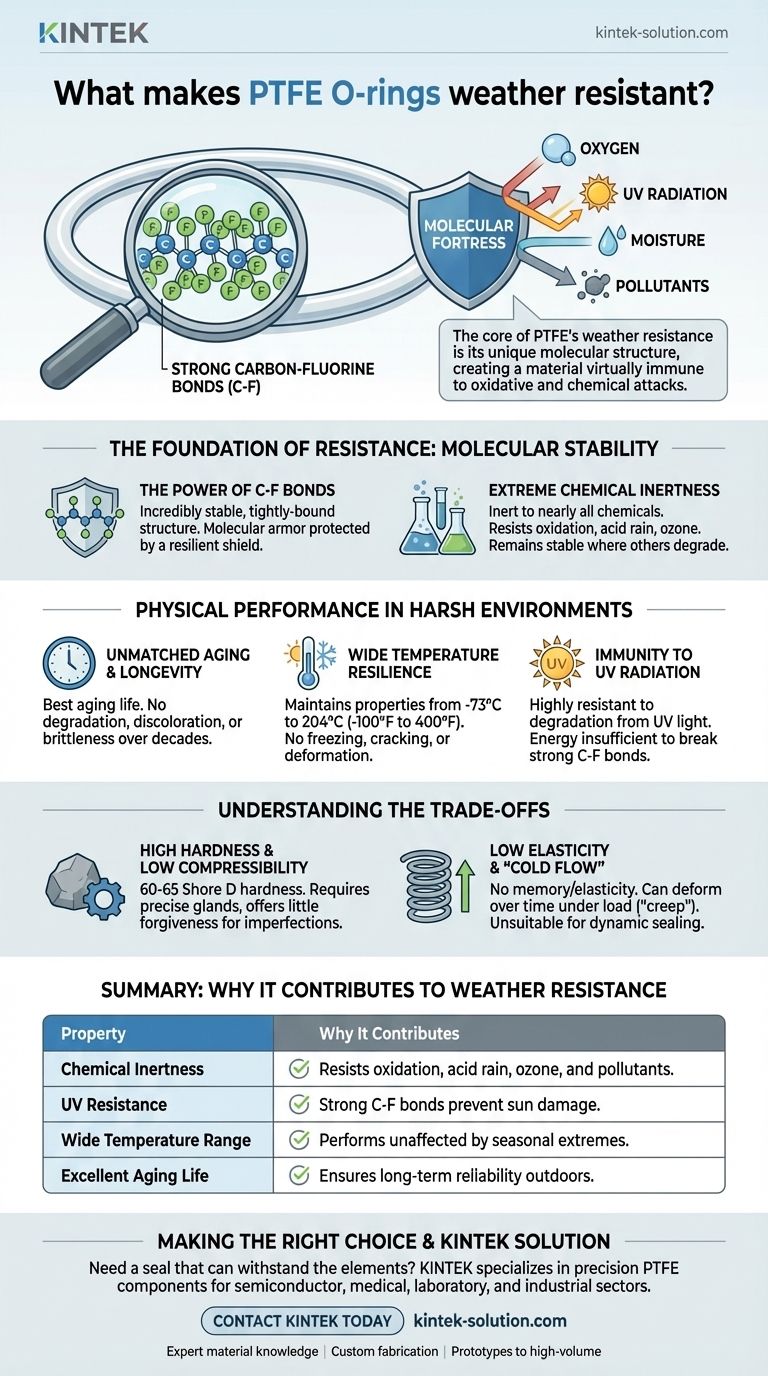

At its core, the remarkable weather resistance of a PTFE O-ring stems from its unique molecular structure. The exceptionally strong chemical bonds between carbon and fluorine atoms create a material that is almost completely chemically inert, meaning it does not react with atmospheric elements like oxygen, UV radiation, or moisture that degrade other materials over time.

The weather resistance of PTFE is not a separately engineered feature but a direct consequence of its fundamental chemical stability. Its powerful carbon-fluorine bonds create a molecular fortress, making the material virtually immune to the oxidative and chemical attacks that constitute "weathering."

The Foundation of Resistance: A Look at Molecular Structure

To understand why PTFE (polytetrafluoroethylene) endures, we must look at its chemistry. The material's resilience is not an additive or a coating; it is an inherent property of its composition.

The Power of Carbon-Fluorine Bonds

The backbone of the PTFE molecule is a chain of carbon atoms, but each carbon atom is completely shielded by fluorine atoms. The bond between a carbon and a fluorine atom (C-F) is one of the strongest single bonds in organic chemistry.

This creates an incredibly stable and tightly-bound structure. Think of it as a form of molecular armor where every vulnerable point is protected by a highly resilient shield, leaving no entry point for chemical attack.

The Consequence: Extreme Chemical Inertness

Because these bonds are so difficult to break, PTFE does not react with its environment. It is inert to nearly all chemicals, including the ones responsible for weathering.

This includes complete resistance to oxidation from atmospheric oxygen, degradation from acid rain, and damage from ozone or other pollutants. While other plastics become brittle and crack, PTFE remains stable.

How Molecular Stability Translates to Physical Performance

This fundamental chemical inertness gives rise to several physical properties that contribute directly to PTFE's longevity and performance in outdoor or harsh environments.

Unmatched Aging and Longevity

PTFE O-rings are often cited as having the best aging life among all plastics. They do not degrade, discolor, or become brittle when exposed to the elements over long periods, ensuring a reliable seal for decades.

Wide Temperature Resilience

Weather involves extreme temperature fluctuations. PTFE maintains its properties across a vast temperature range, typically from -73°C to 204°C (-100°F to 400°F). It will not freeze and crack in extreme cold or deform in high heat.

Immunity to UV Radiation

The same molecular stability that protects PTFE from chemical attack also makes it highly resistant to degradation from ultraviolet (UV) radiation from the sun. The energy in UV light is not sufficient to break the strong carbon-fluorine bonds.

Understanding the Trade-offs

While its weather resistance is nearly absolute, PTFE is not the solution for every sealing application. Its unique properties come with significant mechanical trade-offs.

High Hardness and Low Compressibility

PTFE is a relatively hard material, with a durometer of 60-65 Shore D. Unlike a typical rubber O-ring, it does not compress easily to form a seal. It requires very precise gland designs and offers little forgiveness for surface imperfections.

Low Elasticity and "Cold Flow"

A standard PTFE O-ring has virtually no memory or elasticity. If it is stretched over a part for installation, it will not snap back to its original shape. Furthermore, under a constant load, the material can slowly deform over time in a process known as "creep" or "cold flow." This makes it generally unsuitable for dynamic sealing applications.

Making the Right Choice for Your Application

Selecting a PTFE O-ring requires understanding its strengths and weaknesses in the context of your specific goal.

- If your primary focus is extreme chemical or weather resistance in a static seal: PTFE is the unparalleled choice, offering longevity that no elastomer can match in harsh environments.

- If your primary focus is sealing at extreme temperatures: PTFE's wide operating temperature range makes it a reliable option for static applications in both cryogenic and high-heat conditions.

- If your primary focus is a dynamic seal or one that requires high compressibility: You should look to other materials like FKM (Viton®) or use a specialized spring-energized PTFE seal to compensate for its inherent lack of elasticity.

Ultimately, choosing PTFE is a decision to prioritize chemical and environmental immunity above all else.

Summary Table:

| Property | Why It Contributes to Weather Resistance |

|---|---|

| Chemical Inertness | Resists oxidation, acid rain, ozone, and pollutants that degrade other materials. |

| UV Resistance | Strong C-F bonds are not broken by UV radiation, preventing sun damage. |

| Wide Temperature Range | Performs from -73°C to 204°C (-100°F to 400°F), unaffected by seasonal extremes. |

| Excellent Aging Life | Does not become brittle or discolor, ensuring long-term reliability outdoors. |

Need a seal that can withstand the elements?

PTFE's inherent weather resistance makes it the ideal choice for long-lasting, reliable seals in the semiconductor, medical, laboratory, and industrial sectors. KINTEK specializes in manufacturing precision PTFE components—from custom O-rings and seals to complex labware and liners.

We combine expert material knowledge with custom fabrication capabilities, from prototypes to high-volume orders, to deliver a solution built for your specific environment.

Contact KINTEK today to discuss your application and get a quote for high-performance PTFE components.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance