In short, PTFE expansion bellows are ideal for pharmaceutical processing because their unique combination of chemical inertness, hygienic properties, and regulatory compliance directly addresses the industry's paramount requirements for product purity and safety. They ensure that sensitive materials are not contaminated while accommodating the mechanical stresses within a piping system.

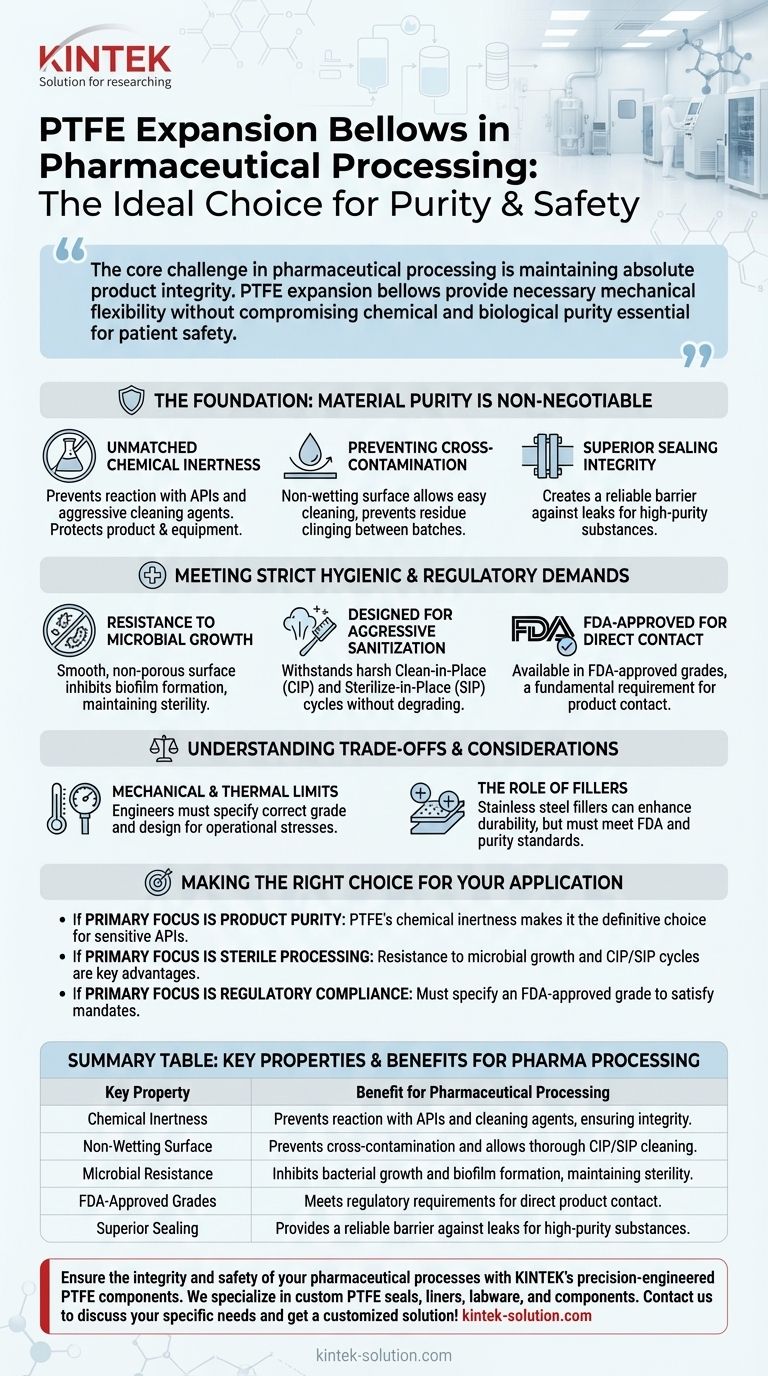

The core challenge in pharmaceutical processing is maintaining absolute product integrity within a dynamic physical environment. PTFE expansion bellows solve this by providing necessary mechanical flexibility without compromising the chemical and biological purity essential for patient safety and regulatory approval.

The Foundation: Why Material Purity is Non-Negotiable

In pharmaceutical manufacturing, every component that comes into contact with a product is a potential source of contamination. The choice of materials like PTFE is a foundational decision designed to eliminate this risk from the outset.

Unmatched Chemical Inertness

PTFE is one of the most non-reactive materials known. This inertness is critical because it ensures the bellows will not react with or degrade valuable active pharmaceutical ingredients (APIs) or the aggressive chemicals used during sterilization and cleaning processes.

This non-corrosive nature protects both the product from contamination and the equipment from damage.

Preventing Cross-Contamination

PTFE has a non-wetting and non-contaminating surface. This means liquids bead up and flow off easily, preventing residue from clinging to the surface after a production cycle is complete.

This property is vital for preventing cross-contamination between different product batches and ensuring the system can be thoroughly cleaned.

Superior Sealing Integrity

The same non-wetting characteristic that aids in cleaning also contributes to superior sealing. It helps create a reliable barrier against leaks, which is essential when handling high-purity or hazardous substances common in pharmaceutical applications.

Meeting Strict Hygienic and Regulatory Demands

Beyond its chemical properties, PTFE is engineered to meet the operational and regulatory standards that define the pharmaceutical industry. These standards are in place to guarantee the final product is safe for human use.

Resistance to Microbial Growth

The smooth, non-porous surface of PTFE is inherently resistant to bacterial adhesion and biofilm formation. This is a crucial hygienic property that helps maintain the sterility of the processing environment.

Designed for Aggressive Sanitization

Pharmaceutical equipment undergoes rigorous cleaning and sterilization, often referred to as Clean-in-Place (CIP) and Sterilize-in-Place (SIP) regimens. PTFE bellows are valued for their ability to withstand these harsh cleaning cycles without degrading.

FDA-Approved for Direct Contact

Critically, PTFE is available in grades that are FDA-approved for direct contact with food and pharmaceutical products. This compliance is not optional; it is a fundamental requirement for any material used in these controlled environments.

Understanding the Trade-offs and Considerations

While PTFE offers an exceptional profile for purity and chemical resistance, it's important to understand its context. No material is a universal solution for every single application.

Mechanical and Thermal Limits

Compared to metal bellows, PTFE has different pressure and temperature limitations. Engineers must specify the correct grade and design of PTFE bellows to ensure they can handle the operational stresses of a specific system without failure.

The Role of Fillers

In some cases, materials like stainless steel can be added to PTFE to enhance durability and strength. While this improves mechanical properties, it's crucial to ensure that any filled PTFE variant still meets the necessary FDA and purity standards for the specific application.

Making the Right Choice for Your Application

Selecting the correct expansion bellow requires aligning the material's strengths with your primary operational goal.

- If your primary focus is product purity: PTFE's chemical inertness and non-contaminating surface make it the definitive choice to protect sensitive APIs.

- If your primary focus is sterile processing: The material's resistance to microbial growth and its ability to withstand aggressive CIP/SIP cycles are its key advantages.

- If your primary focus is regulatory compliance: You must specify an FDA-approved grade of PTFE to satisfy industry and government mandates without question.

Ultimately, choosing PTFE expansion bellows is a strategic decision to uphold the integrity and safety of the entire pharmaceutical process.

Summary Table:

| Key Property | Benefit for Pharmaceutical Processing |

|---|---|

| Chemical Inertness | Prevents reaction with APIs and cleaning agents, ensuring product integrity. |

| Non-Wetting Surface | Prevents cross-contamination and allows for thorough cleaning (CIP/SIP). |

| Microbial Resistance | Inhibits bacterial growth and biofilm formation, maintaining sterility. |

| FDA-Approved Grades | Meets regulatory requirements for direct product contact. |

| Superior Sealing | Provides a reliable barrier against leaks for high-purity or hazardous substances. |

Ensure the integrity and safety of your pharmaceutical processes with KINTEK's precision-engineered PTFE components.

At KINTEK, we specialize in manufacturing high-quality PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures that you receive PTFE expansion bellows and other critical parts that meet the strictest standards for purity, durability, and regulatory compliance.

Let us help you protect your sensitive materials and streamline your operations. Contact us today to discuss your specific needs and get a customized solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What is the function of a teflon check valve in control systems? Prevent Backflow in Corrosive & High-Temp Processes

- What are the main advantages of using Teflon bushings across different industries? Achieve Maintenance-Free Performance

- Why is Teflon difficult to machine to tight tolerances? Overcome Material Instability

- What are the different machining processes suitable for Teflon/PTFE? Master Precision for Soft Materials

- How does CNC machining enhance PTFE part production? Achieve Unmatched Precision & Efficiency

- What situations typically require the use of a spring with PTFE seal elements? Overcome PTFE's Limitations for Reliable Sealing

- In which industries are PTFE gland packings commonly used? For Purity, Chemical Resistance & Reliability

- What are the operating parameters for PTFE bellow mechanical seals? A Guide to Reliable Performance in Corrosive Environments