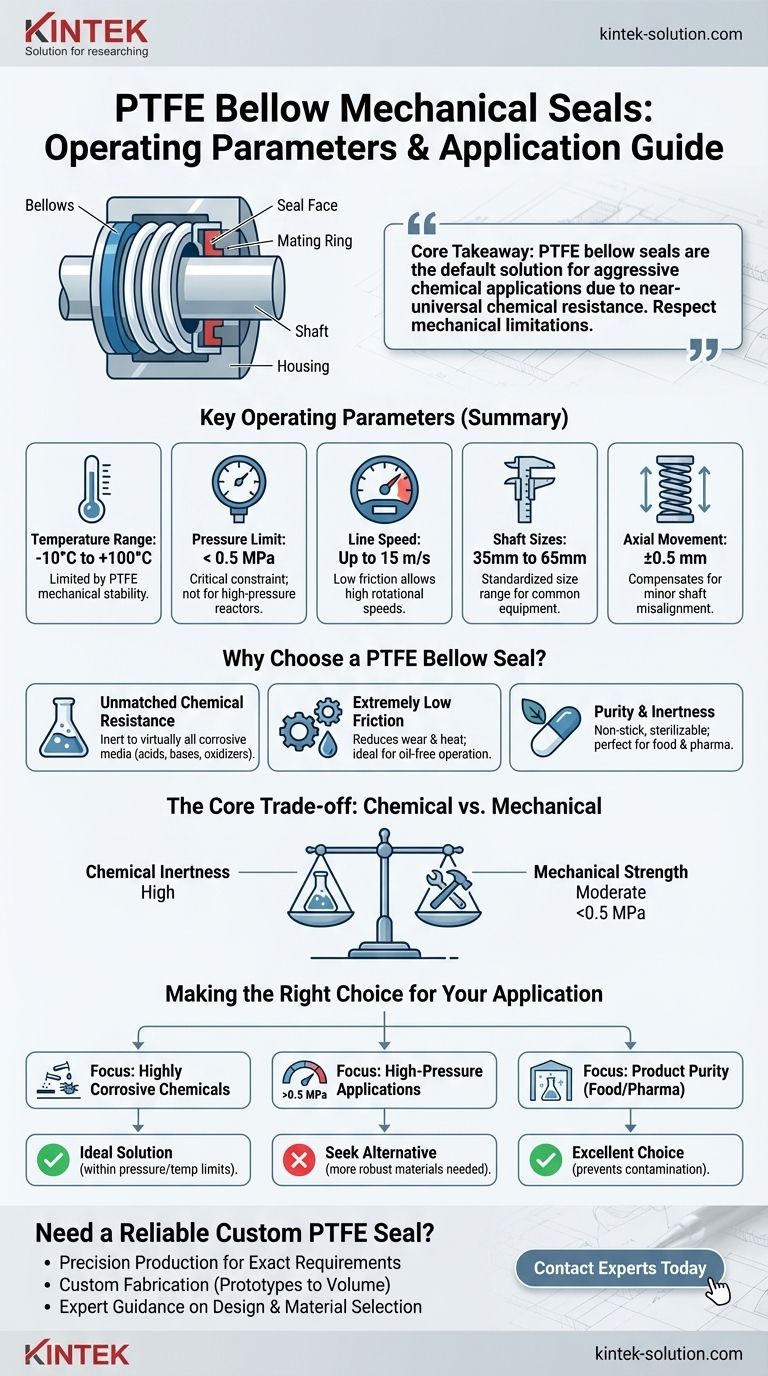

For a standard PTFE bellow mechanical seal, the typical operating parameters are a temperature range of -10°C to +100°C and a pressure limit below 0.5 MPa. These seals are designed for line speeds up to 15 m/s and shaft sizes from 35mm to 65mm, accommodating about ±0.5mm of axial movement. Their primary application is in handling highly corrosive media like strong acids and oxidizing agents.

The core takeaway is that PTFE bellow seals are the default solution for aggressive chemical applications due to PTFE's near-universal chemical resistance. However, you must respect their specific mechanical limitations in pressure and temperature to ensure reliable performance.

Why Choose a PTFE Bellow Seal?

Understanding the unique material properties of Polytetrafluoroethylene (PTFE) is key to knowing when to deploy this type of seal. It is not a universal solution, but it is an unparalleled one in its specific niche.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert materials available, often called the "king of plastic." This allows it to be used for extended periods in virtually any chemical medium without degradation.

This makes it the primary choice for equipment like corrosion-resistant pumps that handle strong acids, bases, and oxidizing agents.

Extremely Low Friction

PTFE possesses an exceptionally low coefficient of friction, one of the lowest of any solid material. This property is critical for reducing wear on the seal faces and the shaft.

Lower friction also means less heat generation and higher efficiency, making it an ideal material for creating an oil-free lubricating seal.

Purity and Inertness

Because PTFE is physiologically inert and has non-stick properties, it is perfectly suited for applications in the food and pharmaceutical industries.

Its surface prevents residue buildup, and it can be effectively sterilized, ensuring the purity of the process media.

Deconstructing the Operating Parameters

Each parameter represents a boundary. Operating within these boundaries ensures the seal's integrity and longevity.

Temperature Range: -10°C to 100°C

This range covers the vast majority of industrial fluid processing temperatures. The limits are defined by the mechanical stability of the PTFE material itself.

Exceeding these temperatures can cause the material to lose its structural integrity, compromising the seal.

Pressure Limitation: < 0.5 MPa

This is a critical constraint. The flexible bellow design, which is excellent for accommodating movement, is also what limits the seal's ability to handle high pressures.

This relatively low pressure rating means PTFE bellow seals are best suited for transfer pumps and low-pressure circulation systems, not high-pressure reactors.

Line Speed: Up to 15 m/s

The low-friction nature of PTFE allows for relatively high rotational speeds without generating destructive levels of heat at the seal faces.

This capability ensures the seal can be used in a wide variety of standard centrifugal pumps.

Axial Movement: ±0.5 mm

The bellow's flexibility is a significant practical advantage. It allows the seal to compensate for minor shaft misalignment and axial movement, which is common in many industrial machines.

This "forgiveness" simplifies installation and helps maintain a consistent seal face contact despite minor equipment imperfections.

Key Advantages and Trade-offs

No engineering choice is without its trade-offs. The strengths of PTFE in one area create limitations in another.

Advantage: The Flexible Bellow Design

The bellow itself acts like a spring, maintaining consistent pressure on the seal faces. Many designs also incorporate a multi-spring structure to distribute this load evenly.

This flexibility ensures a reliable seal even with minor surface imperfections on the mating ring.

Advantage: Complete Sizing and Easy Installation

PTFE bellow seals are available in standardized sizes and are designed for straightforward installation, which reduces maintenance time and complexity.

The Core Trade-off: Chemical vs. Mechanical Properties

The fundamental trade-off is PTFE's world-class chemical resistance versus its moderate mechanical strength. It is softer and more prone to deformation under pressure than metal components.

This is precisely why the pressure is limited to 0.5 MPa. You are choosing chemical inertness at the expense of high-pressure capability.

Making the Right Choice for Your Application

Use these guidelines to determine if a PTFE bellow seal is the correct solution for your specific goal.

- If your primary focus is handling highly corrosive chemicals: This is the ideal application for a PTFE bellow seal, provided your system operates within the stated pressure and temperature limits.

- If your primary focus is high-pressure applications (>0.5 MPa): You must seek an alternative seal design using more robust materials, potentially sacrificing some chemical compatibility for mechanical strength.

- If your primary focus is product purity (food, pharma): The inert, non-stick nature of PTFE makes it an excellent choice for preventing contamination and ensuring clean operation.

By respecting these operating parameters, you can confidently leverage PTFE bellow seals to achieve reliable performance in the most demanding chemical environments.

Summary Table:

| Parameter | Typical Range |

|---|---|

| Temperature Range | -10°C to +100°C |

| Pressure Limit | < 0.5 MPa |

| Line Speed | Up to 15 m/s |

| Shaft Sizes | 35mm to 65mm |

| Axial Movement | ±0.5 mm |

Need a Reliable PTFE Seal for Your Application?

PTFE bellow seals are the ideal solution for handling highly corrosive media, but their performance depends on precise manufacturing and correct specification. KINTEK specializes in the custom fabrication of high-performance PTFE components, including seals, liners, and labware.

We help companies in the semiconductor, medical, laboratory, and industrial sectors by providing:

- Precision Production: Ensuring your seals meet exact mechanical and chemical resistance requirements.

- Custom Fabrication: From initial prototypes to high-volume production runs.

- Expert Guidance: Selecting the right design and material for your specific temperature, pressure, and chemical environment.

Ensure your equipment's reliability—contact our experts today to discuss your PTFE component needs!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How should temperature-related seal performance issues be troubleshooted? A Step-by-Step Guide to Thermal Failure

- What types of PTFE products are available for fluid handling solutions? Your Guide to High-Purity Components

- How does the chemical resistance of PTFE O-rings benefit industrial applications? Ensure Unmatched Sealing Integrity

- What is a floating ball valve and how does it seal line pressure? A Guide to Pressure-Actuated Sealing

- How do modern CNC machines contribute to energy efficiency in Teflon machining? Achieve Precision and Sustainability

- What are the properties of standard Polytetrafluoroethylene (PTFE)? The Ultimate Guide to Its Strengths & Limitations

- What is the friction characteristic of PTFE seals? Achieve Unmatched Low-Friction Performance

- Why is PTFE particularly suitable for high-speed rotary shaft seals? Achieve Superior Performance and Reliability