The durability of PTFE expansion bellows is rooted in the unique molecular properties of Polytetrafluoroethylene itself. This material offers an exceptional combination of chemical inertness, thermal stability, and mechanical flexibility, allowing it to withstand harsh industrial conditions where other materials would quickly degrade and fail.

While the initial investment for PTFE expansion bellows may be higher, their unparalleled resistance to chemical attack, temperature extremes, and mechanical stress results in a significantly lower total cost of ownership. This is achieved through reduced downtime, minimal maintenance, and a dramatically extended service life.

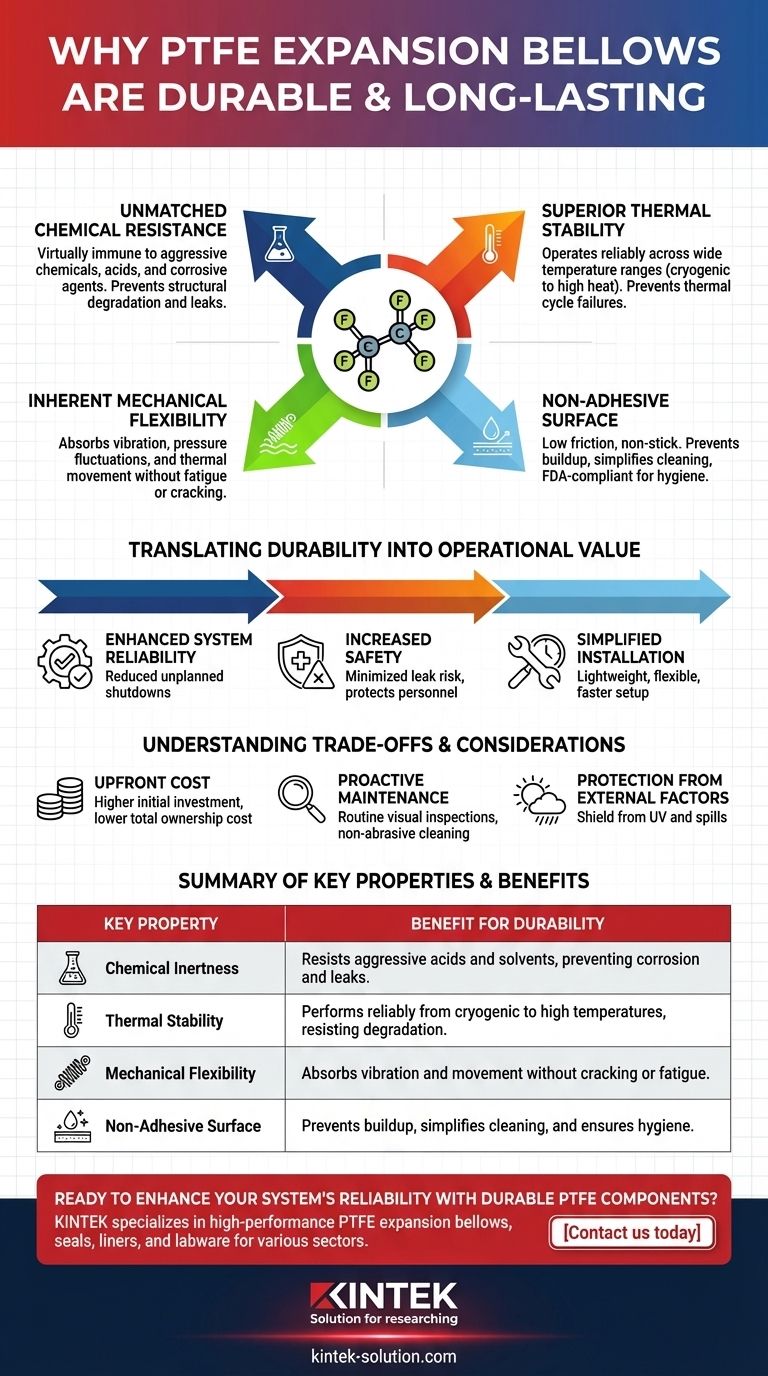

The Core Properties Driving PTFE's Resilience

The longevity of a PTFE expansion bellow is not a single feature but the result of several inherent material characteristics working in concert. Understanding these properties reveals why it is a first-choice material for demanding applications.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert polymers known. It is virtually immune to attack from aggressive chemicals, acids, and corrosive agents that would destroy metal or rubber bellows.

This property ensures the bellow maintains its structural integrity over time, preventing dangerous leaks and system contamination.

Superior Thermal Stability

PTFE expansion bellows can operate reliably across an exceptionally wide temperature range. They do not become brittle in cryogenic conditions or degrade under high heat.

This thermal stability prevents material failure caused by the thermal cycling common in many industrial processes.

Inherent Mechanical Flexibility

Industrial piping systems are dynamic, experiencing vibration, pressure fluctuations, and thermal expansion or contraction.

PTFE bellows are engineered to absorb these movements and stresses without fatiguing or cracking, protecting the entire system from mechanical shock and misalignment.

The Advantage of a Non-Adhesive Surface

PTFE has a very low coefficient of friction and is famously non-stick. This prevents process media from building up on the bellow's surface.

This non-adhesive quality is critical for hygienic applications, as it simplifies cleaning, ensures purity, and is often FDA-compliant for use in food, beverage, and pharmaceutical industries.

Translating Durability into Operational Value

These material properties deliver tangible benefits that impact an operation's bottom line, safety record, and efficiency.

Enhanced System Reliability

By resisting the primary causes of failure—corrosion, thermal degradation, and mechanical fatigue—PTFE bellows significantly reduce the likelihood of unplanned shutdowns.

This translates directly to more predictable operations and higher productivity.

Increased Safety

The integrity of an expansion bellow is paramount when transporting hazardous materials. A component that does not corrode or crack is fundamentally safer.

The reliability of PTFE minimizes the risk of dangerous leaks, protecting personnel and the environment.

Simplified Installation

Compared to heavy and rigid metal alternatives, PTFE bellows are lightweight and flexible.

This makes them significantly easier and faster to install, reducing labor costs and requiring no specialized tools or equipment.

Understanding the Trade-offs and Considerations

While highly effective, choosing PTFE requires a clear understanding of its profile as an engineered component.

The Upfront Cost

The primary consideration is the initial purchase price, which is typically higher than that of rubber or some metal expansion joints.

This cost should be evaluated against the long-term savings from reduced replacement frequency, maintenance, and costly downtime.

The Importance of Proactive Maintenance

PTFE bellows are low-maintenance, not no-maintenance. Their longevity depends on proper care.

Routine visual inspections for cracks, leaks, or deformation are essential to identify potential issues before they lead to failure. The bellows should also be cleaned with non-abrasive agents to remove any external debris.

Protection from External Factors

While internally robust, the bellow's service life can be affected by external conditions.

Protecting the component from extreme UV exposure and accidental chemical splashes or spills will help ensure it reaches its maximum potential lifespan.

Making the Right Choice for Your Application

Selecting the right expansion bellow hinges on your primary operational goal.

- If your primary focus is handling aggressive chemicals: PTFE is the definitive choice due to its near-total chemical inertness, which prevents corrosion and ensures process purity.

- If your primary focus is maximizing system uptime: PTFE's resistance to wear, fatigue, and thermal stress minimizes the risk of component failure and unplanned downtime.

- If your primary focus is maintaining a hygienic environment: The non-stick, FDA-compliant surface of PTFE makes it ideal for food, beverage, and pharmaceutical processing.

- If your primary focus is reducing total cost of ownership: The long service life, durability, and minimal maintenance needs of PTFE consistently offset the higher initial investment over time.

Ultimately, selecting PTFE expansion bellows is an investment in long-term operational stability and peace of mind.

Summary Table:

| Key Property | Benefit for Durability |

|---|---|

| Chemical Inertness | Resists aggressive acids and solvents, preventing corrosion and leaks. |

| Thermal Stability | Performs reliably from cryogenic to high temperatures, resisting degradation. |

| Mechanical Flexibility | Absorbs vibration and movement without cracking or fatigue. |

| Non-Adhesive Surface | Prevents buildup, simplifies cleaning, and ensures hygiene. |

Ready to enhance your system's reliability with durable PTFE components?

At KINTEK, we specialize in manufacturing high-performance PTFE expansion bellows, seals, liners, and labware tailored for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a component that maximizes uptime, safety, and cost-efficiency.

Contact us today to discuss your specific requirements and discover how our PTFE solutions can deliver long-lasting value for your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application