At its core, Polytetrafluoroethylene (PTFE) is an excellent choice for gaskets, rings, and bearings because of its unique combination of three material properties. It possesses an extremely low coefficient of friction, near-universal chemical inertness, and stable performance across a wide range of temperatures. This trifecta makes it one of the most reliable and versatile materials for demanding industrial applications.

While its famous non-stick surface is its most recognized trait, PTFE's true engineering value lies in its operational reliability. It eliminates the need for external maintenance while resisting degradation, ensuring predictable performance and longevity in critical components where failure is not an option.

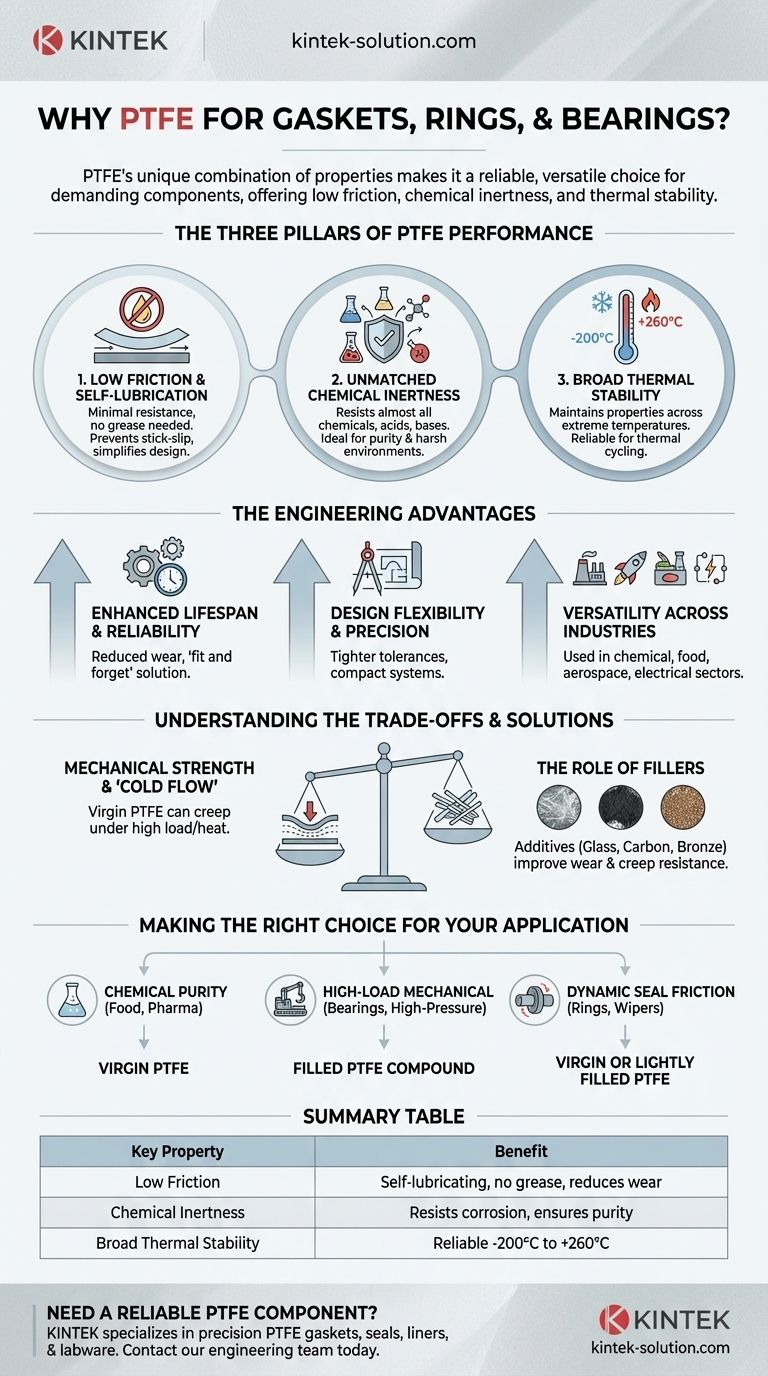

The Three Pillars of PTFE Performance

To understand why PTFE is specified so frequently, we must look at how its fundamental characteristics translate directly into engineering benefits.

Exceptionally Low Friction & Self-Lubrication

PTFE has one of the lowest coefficients of friction of any known solid material. This means surfaces slide against it with minimal resistance.

This property also makes it self-lubricating. Unlike many materials that require grease or oil, PTFE provides its own lubricity, which prevents the "stick-slip" phenomenon common in other seals and bearings.

This eliminates the need for external lubricants, which simplifies design, reduces maintenance, and prevents the accumulation of dirt and contaminants that are often attracted to greased parts.

Unmatched Chemical Inertness

PTFE is chemically inert to nearly all industrial chemicals, acids, and bases. This resistance prevents it from degrading, swelling, or breaking down when exposed to corrosive fluids.

This is the primary reason for its widespread use in gaskets for the chemical processing, pharmaceutical, and food and beverage industries.

Its inertness guarantees product purity, prevents leaks from chemical attack, and gives it a virtually indefinite lifespan in harsh environments.

Broad Thermal Stability

PTFE maintains its key properties across an exceptionally wide temperature range. It remains flexible at cryogenic temperatures and is stable at high temperatures where other polymers would melt or degrade.

This makes it a reliable choice for applications that experience significant thermal cycling, from aerospace engines to power generation facilities.

The Engineering Advantages in Practice

These core properties deliver tangible, real-world benefits that solve common engineering problems related to wear, maintenance, and design complexity.

Enhanced Lifespan and Reliability

The combination of low friction and chemical resistance dramatically reduces wear on mating surfaces. This directly extends the service life of both the PTFE component and the machinery it is part of.

Because it does not require maintenance and is not prone to chemical or fatigue failure, it offers a "fit and forget" solution that increases operational uptime and reliability.

Design Flexibility and Precision

The self-lubricating nature of PTFE allows engineers to design more compact and precise systems. For example, PTFE-lined bearings can be built with tighter tolerances because there is less internal clearance needed for lubrication.

It also provides excellent vibration damping and can tolerate minor misalignments, adding a layer of resilience to mechanical assemblies.

Versatility Across Industries

PTFE's properties make it a go-to material in a vast array of critical sectors.

It is used in petrochemical pipelines for its chemical resistance, in food processing for its hygienic properties, in aerospace for its thermal stability, and in electrical applications for its excellent insulating capabilities.

Understanding the Trade-offs

No material is perfect. While PTFE's advantages are significant, an objective assessment must also consider its limitations.

Mechanical Strength and "Cold Flow"

In its pure, or "virgin," state, PTFE is a relatively soft material. Under a high, sustained load—especially at elevated temperatures—it can be susceptible to creep, also known as "cold flow."

This means the material can slowly deform over time, which can be a critical issue for high-pressure gaskets that need to maintain a constant sealing force.

The Role of Fillers

To overcome the mechanical limitations of virgin PTFE, compounds with fillers are used. Adding materials like glass fiber, carbon, graphite, or bronze dramatically improves its properties.

Filled PTFE grades offer significantly better wear resistance, reduced creep, and a higher capacity to handle pressure-velocity (PV) values in dynamic bearing applications.

Matching the Grade to the Application

It is critical to understand that "PTFE" is a family of materials. Choosing between virgin PTFE and a specific filled grade is essential for success.

The operational demands—pressure, temperature, mating surface material, and required lifespan—will dictate which formulation is the correct engineering choice.

Making the Right Choice for Your Application

Selecting the correct type of PTFE requires a clear understanding of your primary goal.

- If your primary focus is chemical purity and compliance (food, pharma): Virgin PTFE is almost always the correct choice due to its unmatched inertness and lack of additives.

- If your primary focus is high-load mechanical performance (bearings, high-pressure gaskets): A filled PTFE compound is necessary to resist creep and provide the required durability.

- If your primary focus is reducing friction in a dynamic seal (rings, wipers): The exceptional self-lubricating properties of either virgin or a lightly filled PTFE will deliver optimal performance.

By understanding these core principles, you can select the precise PTFE formulation that delivers maximum reliability for your specific engineering challenge.

Summary Table:

| Key Property | Benefit for Gaskets, Rings & Bearings |

|---|---|

| Low Coefficient of Friction | Self-lubricating, eliminates need for external grease, reduces wear |

| Chemical Inertness | Resists corrosion from acids, bases, and solvents; ensures product purity |

| Broad Thermal Stability | Performs reliably from cryogenic to high temperatures (-200°C to +260°C) |

Need a reliable PTFE component for your critical application?

At KINTEK, we specialize in manufacturing precision PTFE components—including custom gaskets, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need the chemical purity of virgin PTFE or the enhanced mechanical strength of a filled compound, our expertise ensures you get the right material for superior performance and longevity.

Contact our engineering team today to discuss your specific requirements and receive a custom solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications