At its core, Polytetrafluoroethylene (PTFE) revolutionized engineering by combining three properties rarely found together in a single, machinable material: an extremely low coefficient of friction, near-total chemical inertness, and stability across a vast temperature range. This unique combination solves critical, simultaneous challenges related to wear, corrosion, and environmental resilience that previously required far more complex and expensive solutions.

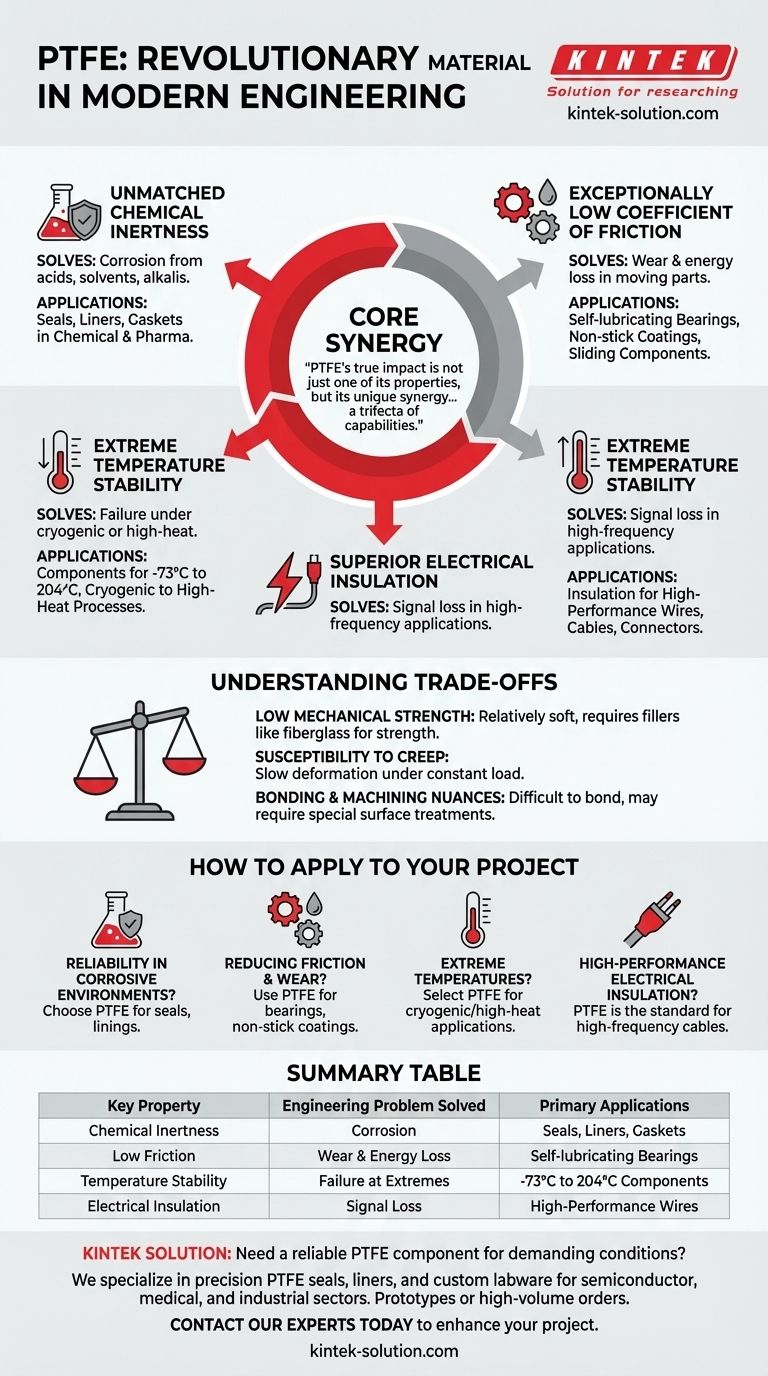

PTFE's true impact is not just one of its properties, but its unique synergy. It empowers engineers to design systems that can withstand extreme chemicals, operate with minimal friction, and endure wide temperature fluctuations—a trifecta of capabilities that unlocks new levels of performance and durability.

The Core Properties That Drive Innovation

To understand why PTFE, commonly known by the brand name Teflon, is so indispensable, we must examine the specific engineering problems each of its key properties solves.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, including strong acids, alkalis, and organic solvents. This makes it an ideal material for seals, gaskets, and linings in chemical processing and pharmaceutical industries.

Where other materials would corrode and fail, PTFE components provide a reliable and long-lasting barrier, ensuring both safety and product purity.

An Exceptionally Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid. This "non-stick" quality is fundamental to its value in mechanical systems.

It allows for the creation of self-lubricating bearings and low-friction coatings that dramatically reduce wear and energy loss in moving parts. This is critical in large-scale civil engineering, where PTFE bearing pads allow bridges and buildings to accommodate thermal expansion and seismic movement safely.

Extreme Temperature Stability

PTFE performs reliably across an exceptionally wide temperature range, typically from -73°C to 204°C (-100°F to 400°F).

This allows it to be used in demanding applications from cryogenic fluid handling to high-temperature industrial processes without degrading, becoming brittle, or losing its essential properties.

Superior Electrical Insulation

As an excellent electrical insulator, PTFE is vital in electronics and electrical engineering. Its properties are stable across a wide range of frequencies.

This makes it a preferred material for insulating high-performance wires, cables, and connectors, especially in high-frequency applications where signal integrity is paramount.

Understanding the Trade-offs and Limitations

No material is perfect, and a clear-eyed technical assessment requires acknowledging PTFE's limitations. Its revolutionary properties come with inherent trade-offs that engineers must manage.

Relatively Low Mechanical Strength

PTFE is a relatively soft material with low tensile strength and wear resistance compared to metals or harder plastics. It is not suitable for purely structural components that bear significant loads.

To overcome this, engineers often use fillers like fiberglass, carbon, or bronze to create PTFE composites. These additives significantly improve mechanical strength, creep resistance, and durability while retaining PTFE's core benefits.

Susceptibility to Creep

Under a constant, sustained load, PTFE can slowly deform over time, a phenomenon known as "creep." This must be accounted for in the design of long-term applications like seals and bearing pads.

Bonding and Machining Nuances

While PTFE is highly machinable, its non-stick surface makes it notoriously difficult to bond to other materials using conventional adhesives. This often requires specialized surface treatments or mechanical fastening.

How to Apply This to Your Project

Choosing a material depends entirely on the primary problem you need to solve. PTFE is often the definitive answer when a specific set of challenges is present.

- If your primary focus is reliability in corrosive environments: PTFE is an unparalleled choice for seals, linings, and fluid-handling components that must not react with aggressive chemicals.

- If your primary focus is reducing friction and wear: Use PTFE for self-lubricating bearings, non-stick coatings, and sliding components where minimizing energy loss and physical degradation is critical.

- If your primary focus is performance across extreme temperatures: Select PTFE for components that must function reliably in both cryogenic and high-heat applications without failure.

- If your primary focus is high-performance electrical insulation: PTFE is the industry standard for insulating high-frequency cables and connectors where signal loss is unacceptable.

Ultimately, PTFE's revolutionary status comes from its ability to solve multiple, often conflicting, engineering problems with a single, reliable material.

Summary Table:

| Key Property | Engineering Problem Solved | Primary Applications |

|---|---|---|

| Chemical Inertness | Corrosion from acids, solvents, and alkalis | Seals, liners, gaskets in chemical processing |

| Low Coefficient of Friction | Wear and energy loss in moving parts | Self-lubricating bearings, non-stick coatings |

| Extreme Temperature Stability | Failure under cryogenic or high-heat conditions | Components for -73°C to 204°C environments |

| Superior Electrical Insulation | Signal loss in high-frequency applications | Insulation for high-performance wires & cables |

Need a reliable PTFE component that can withstand your most demanding conditions?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a prototype or a high-volume order, our expertise in custom fabrication ensures you get a solution that leverages PTFE's revolutionary properties for your specific application.

Contact our experts today to discuss how we can enhance your project's performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications