At its core, the durability of Medical Grade PTFE Liners is a direct result of its unique molecular structure. This structure provides a powerful combination of chemical inertness, physical toughness, and environmental resilience, ensuring the material maintains its integrity and performance throughout the demanding lifecycle of a medical device.

The exceptional durability of PTFE is not due to a single property, but rather a synergistic effect of its chemical non-reactivity, physical resilience against wear, and stability across extreme temperatures and pressures, making it uniquely reliable for critical medical applications.

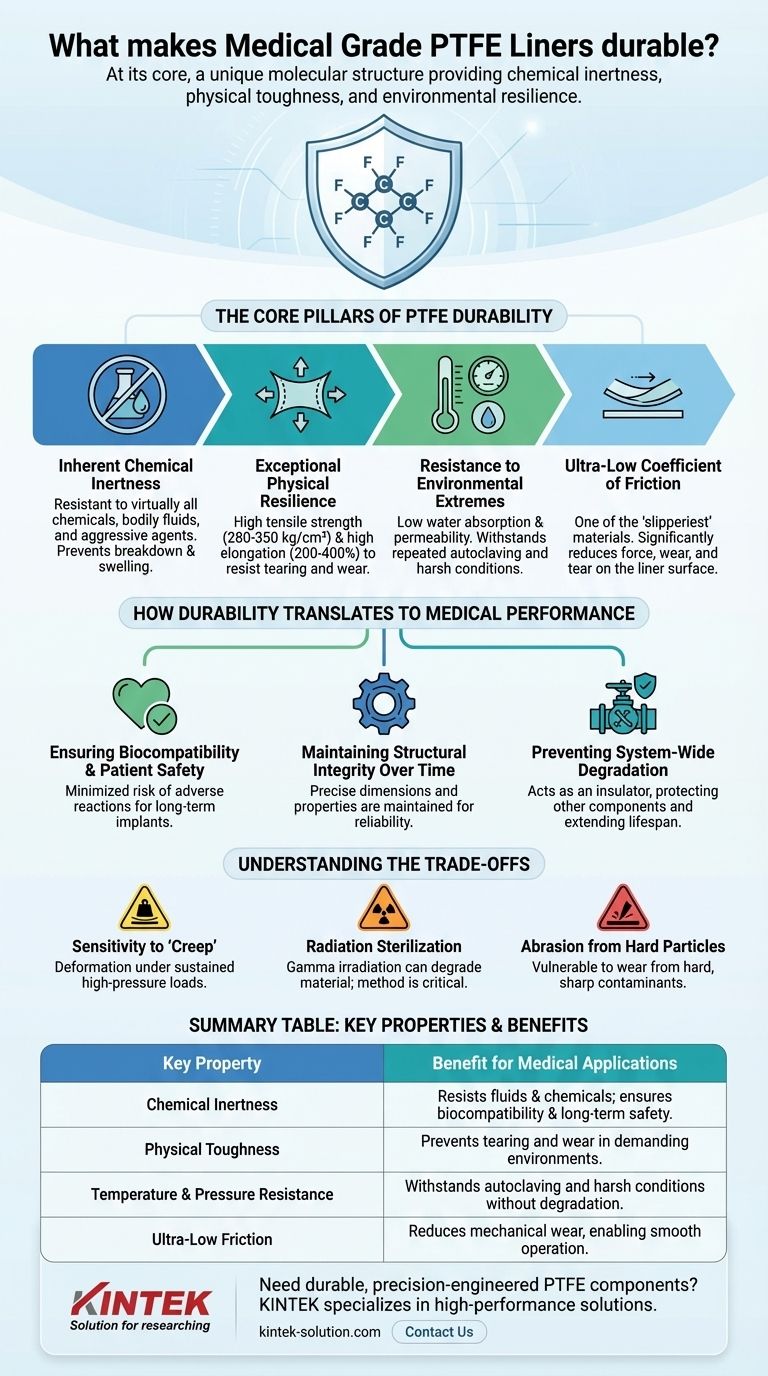

The Core Pillars of PTFE Durability

To understand why PTFE liners are so durable, we must examine the specific properties that contribute to their longevity and reliability in a medical environment.

Inherent Chemical Inertness

Polytetrafluoroethylene (PTFE) is one of the most non-reactive substances known. Its molecular bonds are incredibly strong, making it resistant to degradation from virtually all chemicals, bodily fluids, and aggressive cleaning agents.

This inertness is fundamental to its durability, as it prevents the material from breaking down, swelling, or changing its properties when exposed to the complex biological and chemical environment inside the body or a laboratory.

Exceptional Physical Resilience

PTFE exhibits impressive physical toughness. It has a high tensile strength, typically between 280-350 kg/cm², and can stretch significantly (200-400%) before breaking, a property known as high elongation.

This combination means the material can resist tearing and wear from mechanical stress. It maintains its structural integrity even when subjected to the repeated movements required of devices like catheters or articulating surgical tools.

Resistance to Environmental Extremes

Medical devices must often endure harsh conditions, from high-pressure internal environments to high-temperature sterilization processes. PTFE excels in these scenarios.

It has very low water absorption and permeability, meaning it won't weaken or change shape when exposed to moisture. Furthermore, it can withstand repeated autoclaving cycles without degrading, a critical factor for reusable medical equipment.

Ultra-Low Coefficient of Friction

A key contributor to mechanical durability is PTFE's extremely low friction—it is one of the "slipperiest" materials available.

This property significantly reduces the force needed for devices to move, which in turn minimizes wear and tear on the liner surface. For a catheter navigating blood vessels, this means smoother passage and a longer functional life for the device.

How Durability Translates to Medical Performance

These intrinsic properties are not just abstract benefits; they directly impact patient safety, device reliability, and procedural success.

Ensuring Biocompatibility and Patient Safety

The chemical inertness of PTFE is the foundation of its biocompatibility. Because it does not react with bodily tissues or fluids, the risk of adverse reactions, inflammation, or rejection is minimized. This biological durability is paramount for implants and devices in long-term contact with the body.

Maintaining Structural Integrity Over Time

The combination of chemical resistance, low moisture absorption, and physical toughness ensures that PTFE liners maintain their precise dimensions and properties for the long term. This reliability is crucial for devices where even minor changes in shape or function could compromise performance.

Preventing System-Wide Degradation

In complex assemblies, a PTFE liner can act as an insulator, protecting other components. By lining a metal valve, for instance, the PTFE prevents corrosive chemicals from attacking the metal parts, extending the lifespan and reliability of the entire system.

Understanding the Trade-offs

While exceptionally durable, no material is without limitations. An objective assessment requires acknowledging key design considerations.

Sensitivity to "Creep"

Under sustained, high-pressure loads, PTFE can be susceptible to a phenomenon known as "creep" or cold flow, where the material slowly deforms over time. Engineers must account for this behavior in applications involving constant high mechanical stress.

Radiation Sterilization

While PTFE is highly resistant to heat-based sterilization like autoclaving, certain types of radiation, such as gamma irradiation, can degrade the material by breaking its molecular chains. This makes the choice of sterilization method a critical consideration.

Abrasion from Hard Particles

Although resistant to wear from smooth surfaces, PTFE's relative softness means it can be abraded by hard, sharp particles. In applications where such contaminants are possible, system filtration and design must be carefully managed.

Making the Right Choice for Your Goal

The decision to use a Medical Grade PTFE Liner should be based on its unique ability to meet the primary demands of your application.

- If your primary focus is long-term implantation and patient safety: The unmatched chemical inertness and biocompatibility of PTFE make it the definitive choice to prevent adverse tissue reactions.

- If your primary focus is device functionality and smooth operation: The ultra-low coefficient of friction is the key property, ensuring minimal wear and consistent, reliable mechanical performance.

- If your primary focus is reusability and sterilization: PTFE's ability to withstand repeated autoclaving without degrading ensures device longevity and hygiene.

Ultimately, the trust placed in Medical Grade PTFE is built on its fundamental material science, which provides a robust and predictable foundation for durable performance.

Summary Table:

| Key Property | Benefit for Medical Applications |

|---|---|

| Chemical Inertness | Resists bodily fluids, chemicals, and cleaning agents; ensures biocompatibility and long-term safety. |

| Physical Toughness | High tensile strength and elongation prevent tearing and wear in demanding environments. |

| Temperature & Pressure Resistance | Withstands repeated autoclaving and harsh conditions without degradation. |

| Ultra-Low Friction | Reduces mechanical wear, enabling smooth operation of devices like catheters. |

Need durable, precision-engineered PTFE components for your medical, semiconductor, or laboratory applications?

KINTEK specializes in manufacturing high-performance PTFE seals, liners, and labware with exacting standards for durability and reliability. Whether you require prototypes or high-volume orders, our custom fabrication ensures your components meet the rigorous demands of your industry.

Contact us today to discuss your project and discover how our PTFE solutions can enhance your product's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- What industrial applications does PTFE have? Unlock Performance in Extreme Environments

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- What are the primary applications of PTFE? Unlocking High-Performance Solutions