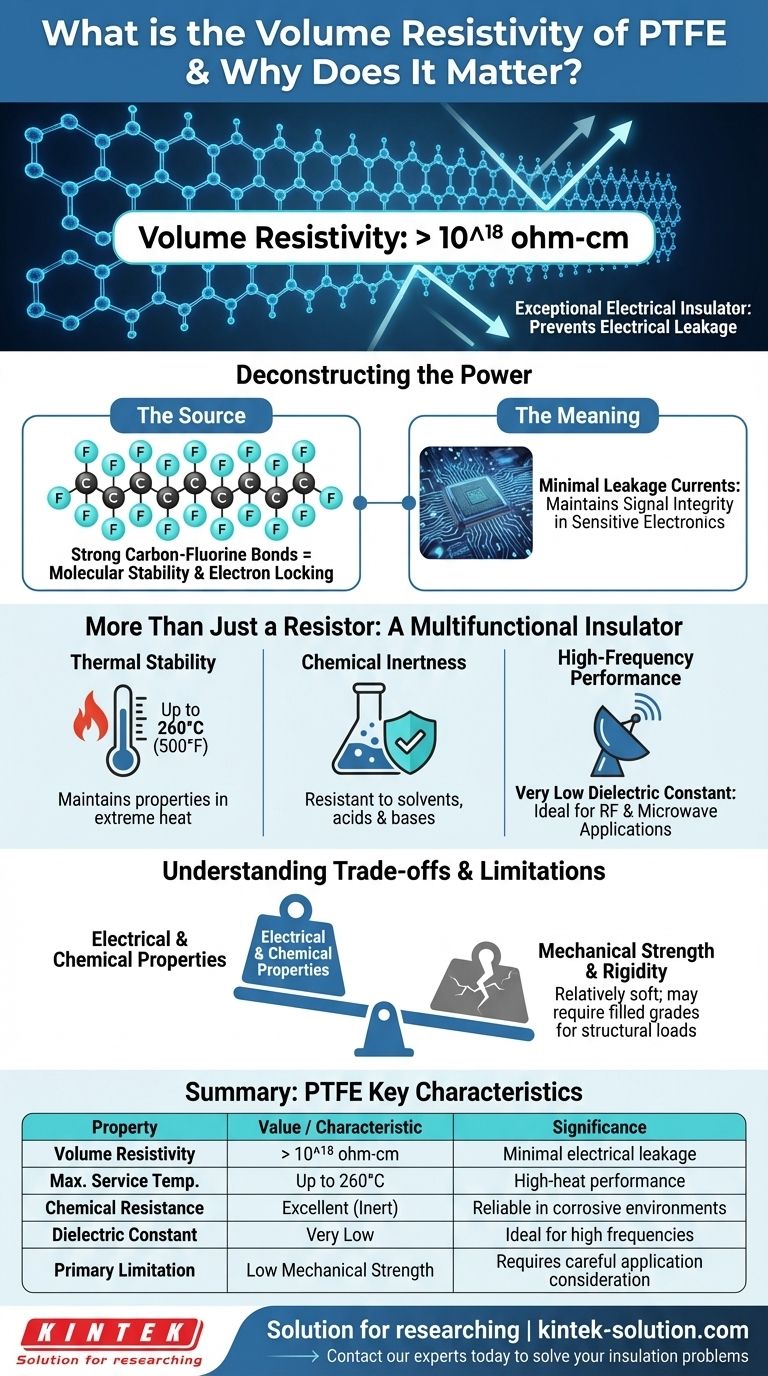

To put it directly, Polytetrafluoroethylene (PTFE) has an exceptionally high volume resistivity, typically exceeding 10^18 ohm-cm. This value places it among the best solid electrical insulators known. This property is significant because it ensures that electricity cannot easily flow through the material, making it a premier choice for preventing electrical leakage in a wide array of demanding applications.

The core significance of PTFE's volume resistivity isn't just the high number itself, but how this elite insulating capability works in concert with its unmatched thermal stability and chemical inertness, making it reliable in extreme environments where other insulators would fail.

Deconstructing PTFE's Electrical Performance

The defining electrical characteristic of PTFE is its profound resistance to the flow of electricity. This is not an incidental feature but a direct result of its unique molecular structure, which has critical implications for its use.

What 10^18 ohm-cm Truly Means

Volume resistivity is a measure of a material's intrinsic ability to oppose the flow of electrical current through its bulk. A value as high as 10^18 ohm-cm indicates an almost complete inability for electrons to move through the material.

This ensures that when PTFE is used as an insulator, leakage currents are minimal. This is vital for maintaining signal integrity in sensitive electronics and preventing energy loss or short circuits in high-voltage systems.

The Source of Its Insulating Power

PTFE's remarkable electrical properties stem from its molecular makeup. The polymer is composed of long chains of carbon atoms completely sheathed by fluorine atoms.

The carbon-fluorine bond is exceptionally strong and stable. This, combined with the symmetrical arrangement of the fluorine atoms, creates a non-polar molecule with very little free electrical charge, effectively locking electrons in place.

More Than Just a Resistor: A Multifunctional Insulator

Choosing a material is rarely about a single property. PTFE's value skyrockets because its world-class electrical insulation is paired with other extreme-performance characteristics.

Unmatched Thermal Stability

PTFE can operate continuously at temperatures up to 260°C (500°F) without significant degradation of its physical or electrical properties. Many insulating materials fail long before reaching such temperatures, making PTFE essential for high-temperature wiring, connectors, and components.

Superior Chemical Inertness

The material is famously non-reactive, showing resistance to nearly all common solvents, acids, and bases. This allows PTFE to be used as a reliable insulator in corrosive chemical environments where other materials would quickly corrode and fail, leading to catastrophic electrical shorts.

Excellent Dielectric Properties for High Frequencies

Beyond just resisting current flow, PTFE has a very low dielectric constant and dissipation factor. These properties are critical for high-frequency applications, such as in radio frequency (RF) cables and printed circuit boards (PCBs).

A low dielectric constant ensures that signals pass through with minimal delay or distortion, preserving the integrity of high-speed data transmission.

Understanding the Trade-offs and Limitations

No material is perfect, and unwavering objectivity requires acknowledging where PTFE falls short. Its exceptional electrical and chemical properties come at the cost of mechanical robustness.

Low Mechanical Strength and Rigidity

PTFE is a relatively soft and flexible material. It has low tensile strength and rigidity compared to engineering plastics like PEEK or nylon. This makes it unsuitable for applications that require a component to bear a significant mechanical load.

Considerations for Filled Grades

To improve its mechanical properties, PTFE is often mixed with fillers like glass, carbon, or bronze. While these "filled grades" are mechanically stronger, the additives can slightly alter the pristine electrical properties of virgin PTFE. For the most sensitive electrical or high-frequency applications, this trade-off must be carefully evaluated.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its profile with your primary engineering goal. PTFE's high volume resistivity makes it a powerful but specific tool.

- If your primary focus is pure electrical insulation: PTFE is a top-tier choice due to its phenomenal volume resistivity, which guarantees minimal current leakage.

- If your application involves high frequencies (RF/Microwave): PTFE is an ideal solution because its high resistivity is combined with an essential low dielectric constant, preserving signal integrity.

- If you need insulation in extreme temperatures or harsh chemical environments: PTFE's unique combination of high resistivity, thermal stability, and chemical inertness makes it one of the few viable options.

- If your component must also bear a significant mechanical load: You must consider either a filled grade of PTFE or an entirely different material, as the low strength of its virgin form is a key limitation.

Ultimately, PTFE's high volume resistivity is the cornerstone of a unique property set that makes it an indispensable material for the world's most challenging electrical applications.

Summary Table:

| Property | Value / Characteristic | Key Significance |

|---|---|---|

| Volume Resistivity | > 10^18 ohm-cm | Ensures minimal electrical leakage and current flow. |

| Maximum Service Temperature | Up to 260°C (500°F) | Maintains properties in high-heat environments. |

| Chemical Resistance | Excellent (Inert) | Performs reliably in corrosive environments. |

| Dielectric Constant | Very Low | Ideal for high-frequency applications (RF/Microwave). |

| Primary Limitation | Low Mechanical Strength | May require filled grades for structural applications. |

Need a Reliable Insulator for Demanding Conditions?

PTFE's exceptional volume resistivity, thermal stability, and chemical resistance make it the ideal choice for critical components in the semiconductor, medical, laboratory, and industrial sectors.

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom seals, liners, and labware. We work with you from prototype to high-volume production to ensure your parts meet the strictest electrical and environmental requirements.

Let us help you solve your most challenging insulation problems. Contact our experts today to discuss your project needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications