In short, Molybdenum Disulfide (MoS2), often called "Moly," is added to PTFE to act as a dry lubricant. This combination dramatically improves the material's anti-friction properties and its resistance to wear, far beyond what pure PTFE can offer.

The core purpose of adding MoS2 to PTFE is to create a synergistic composite. You retain PTFE's naturally low friction while introducing a robust, self-lubricating mechanism that significantly enhances the material's hardness, wear resistance, and ability to perform under load.

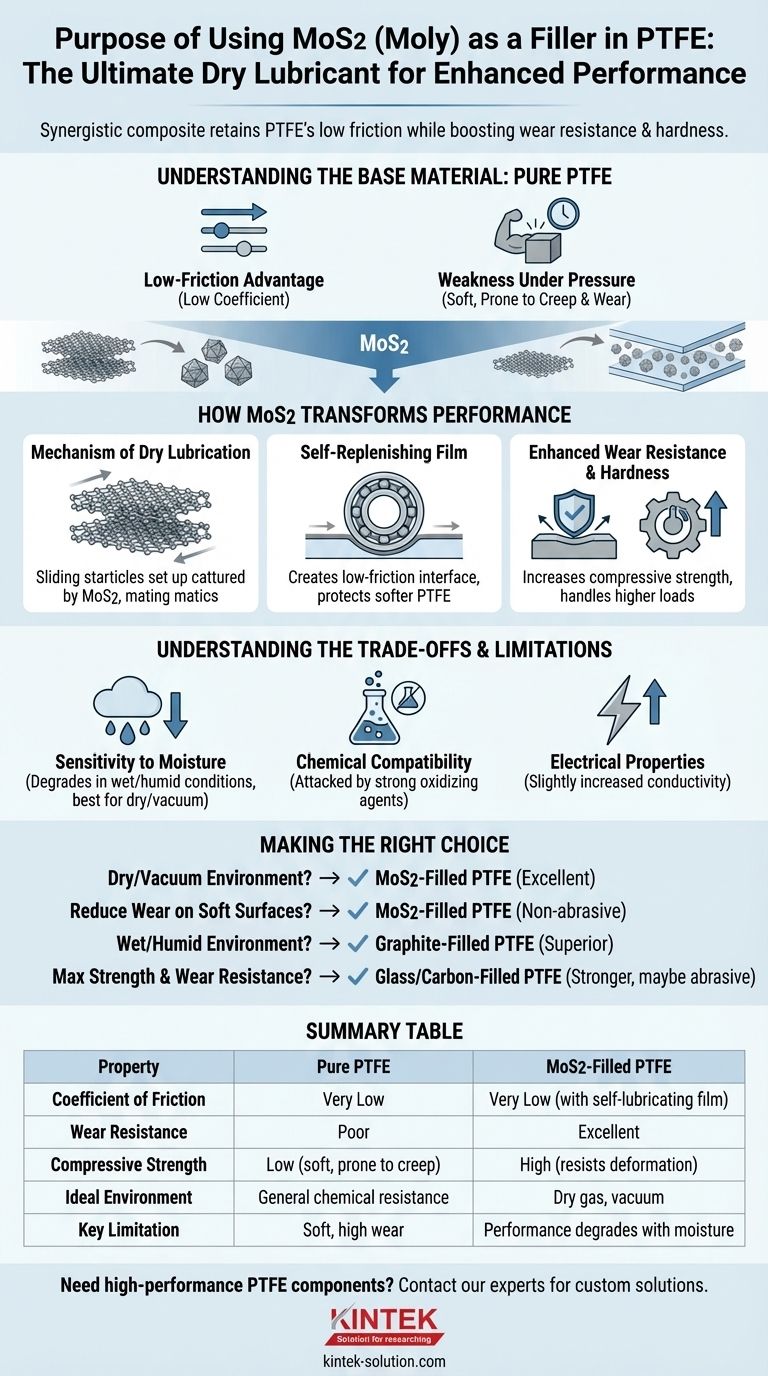

Understanding the Base Material: Pure PTFE

The Low-Friction Advantage

Pure Polytetrafluoroethylene (PTFE) is famous for having one of the lowest coefficients of friction of any solid material. This inherent slipperiness makes it a natural choice for bearings, seals, and other low-friction applications.

The Weakness Under Pressure

Despite its low friction, pure PTFE is a relatively soft material. It suffers from two key weaknesses: poor wear resistance and a tendency to "creep" or deform permanently when a load is applied over time. This limits its use in more demanding mechanical applications.

How MoS2 Transforms PTFE's Performance

The Mechanism of Dry Lubrication

Molybdenum Disulfide has a layered, crystalline structure, much like graphite. These layers can slide against each other with very little force, allowing MoS2 to function as a highly effective solid lubricant.

A Self-Replenishing Film

When blended into PTFE, the MoS2 particles become distributed throughout the material matrix. As a component like a bearing or seal begins to move, a thin film of MoS2 is transferred to the mating surfaces, creating an incredibly low-friction interface.

Enhanced Wear Resistance

This self-lubricating film serves a dual purpose. Not only does it lower friction, but it also protects the softer PTFE base material from abrasive wear. This drastically extends the operational lifespan of the component.

Increased Hardness and Stiffness

Like most fillers, MoS2 also increases the overall hardness and compressive strength of the PTFE. This helps the material resist deformation and creep, allowing it to handle higher loads and pressures than its pure counterpart.

Understanding the Trade-offs and Limitations

Sensitivity to Moisture

The primary trade-off with MoS2 is its performance in humid environments. The lubricating properties of MoS2 degrade in the presence of moisture, making it best suited for dry gas or vacuum applications. For wet service, graphite is often a better choice.

Chemical Compatibility

While PTFE itself is almost entirely chemically inert, the MoS2 filler can be attacked by strong oxidizing agents. This slightly narrows the range of chemical environments where the composite can be used compared to pure PTFE.

Electrical Properties

Pure PTFE is an excellent electrical insulator. The addition of MoS2 can slightly increase the material's electrical conductivity. This is a critical consideration for applications requiring high dielectric strength.

Making the Right Choice for Your Application

Choosing the correct material depends entirely on the operational environment and performance requirements.

- If your primary focus is operating in a vacuum or very dry environment: MoS2-filled PTFE is an exceptional choice due to its superior dry lubrication properties.

- If your primary focus is reducing wear on a soft mating surface (like aluminum or brass): MoS2-filled PTFE is ideal because it provides lubricity without being abrasive.

- If your primary focus is operating in a wet or humid environment: A graphite-filled PTFE is often a superior choice, as its lubricity is enhanced by moisture.

- If your primary focus is maximum compressive strength and wear resistance: A glass or carbon-filled PTFE will typically outperform a Moly-filled variant, though they may be more abrasive to mating surfaces.

By understanding the specific role of the MoS2 filler, you can select a material precisely engineered for your application's unique demands.

Summary Table:

| Property | Pure PTFE | MoS2-Filled PTFE |

|---|---|---|

| Coefficient of Friction | Very Low | Very Low (with self-lubricating film) |

| Wear Resistance | Poor | Excellent |

| Compressive Strength / Hardness | Low (soft, prone to creep) | High (resists deformation) |

| Ideal Environment | General chemical resistance | Dry gas, vacuum |

| Key Limitation | Soft, high wear | Performance degrades with moisture |

Need a high-performance PTFE component engineered for demanding applications?

At KINTEK, we specialize in precision manufacturing of custom PTFE components, including advanced composites like MoS2-filled PTFE. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures your parts deliver superior wear resistance and reliable lubrication under load.

We provide custom fabrication from prototypes to high-volume orders, ensuring your specifications are met with exacting precision.

Contact our experts today to discuss how our PTFE solutions can solve your specific challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability