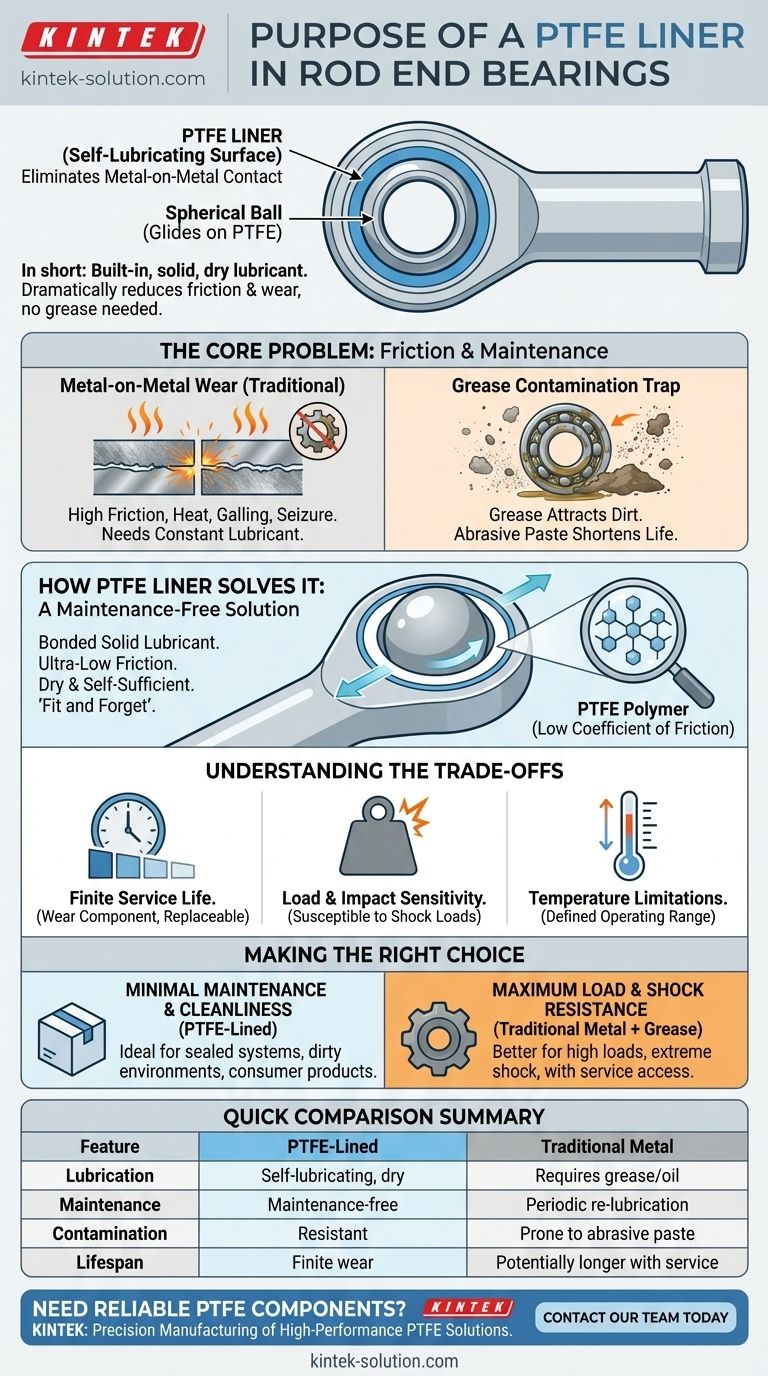

In short, a PTFE liner is a built-in, self-lubricating surface inside a rod end bearing. Its primary purpose is to eliminate direct metal-on-metal contact between the ball and the outer race. This dramatically reduces friction and wear, removing the need for traditional grease or oil lubrication.

The central purpose of a PTFE liner is to transform a standard rod end into a maintenance-free component. By acting as a solid, dry lubricant, it solves the persistent engineering challenges of friction, contamination, and the need for periodic re-lubrication.

The Core Problem: Friction and Maintenance

To understand the value of a PTFE liner, we must first recognize the fundamental problems it solves in traditional metal-on-metal bearings.

The Inevitability of Metal-on-Metal Wear

Without a lubricating layer, two moving metal surfaces will generate significant friction and heat. This leads to galling, accelerated wear, and eventual seizure of the joint. The only way to prevent this is with a constant supply of lubricant.

The Contamination Trap of Grease

While grease is an effective lubricant, it has a significant downside: it is sticky. In many industrial or automotive environments, grease attracts dirt, dust, and grit, creating an abrasive paste that can severely shorten the bearing's lifespan.

How a PTFE Liner Solves the Problem

A PTFE-lined bearing is engineered to overcome these issues by fundamentally changing how the moving surfaces interact.

A Bonded, Solid Lubricant

The liner isn't a separate part but is permanently bonded to the inner surface of the bearing's body, or outer race. The spherical ball then rides directly on this low-friction PTFE surface, preventing any metal-to-metal contact.

The Science of Low Friction

PTFE, or Polytetrafluoroethylene, is a synthetic polymer with an extremely low coefficient of friction. As the ball moves, it slides effortlessly against the liner. This action provides constant, dry lubrication without requiring any external substance.

Designed for "Fit and Forget" Applications

Because the lubrication is integral to the bearing itself, it becomes a self-sufficient system. This is invaluable in applications where regular maintenance is difficult, impractical, or likely to be forgotten. It also keeps the assembly clean, as there is no wet grease to seep out.

Understanding the Trade-offs

While highly effective, PTFE-lined bearings are not a universal solution. Their design introduces specific considerations that must be understood.

Finite Service Life

The PTFE liner is a wear component. Over thousands of cycles, the liner will eventually wear away. Unlike a greasable bearing that can be serviced, a worn PTFE-lined bearing must be replaced.

Load and Impact Sensitivity

While strong, the liner can be more susceptible to damage from extreme shock loads or contamination being forced into the joint than a robust metal-on-metal bearing. The material can be displaced or compromised under forces that exceed its design specifications.

Temperature Limitations

PTFE has excellent resistance to high temperatures, but it still has a defined operating range. In applications with extreme heat cycles, you must ensure the liner's material properties are suitable.

Making the Right Choice for Your Application

Selecting the correct bearing type depends entirely on the demands of your specific use case.

- If your primary focus is minimal maintenance and cleanliness: A PTFE-lined rod end is the superior choice, ideal for sealed systems or consumer products where servicing is not expected.

- If your application is in a dirty or dusty environment: The dry lubrication of a PTFE liner is a significant advantage, as it prevents the abrasive paste effect seen with grease.

- If your primary focus is maximum load capacity and shock resistance: A traditional, high-quality metal-on-metal bearing with a proper greasing schedule may offer greater durability in the most abusive conditions.

By understanding the PTFE liner's function, you can select a component that perfectly aligns with the operational demands and service life of your project.

Summary Table:

| Feature | PTFE-Lined Bearing | Traditional Metal Bearing |

|---|---|---|

| Lubrication | Self-lubricating, dry | Requires grease/oil |

| Maintenance | Maintenance-free | Periodic re-lubrication needed |

| Contamination | Resistant (no sticky grease) | Prone to abrasive paste from dirt |

| Lifespan | Finite (wear component) | Potentially longer with service |

| Ideal For | Sealed systems, dirty environments, low-maintenance needs | High-load, high-shock applications with maintenance access |

Need a reliable, self-lubricating PTFE component for your application?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures you get a solution that delivers low friction, excellent chemical resistance, and long-term reliability—from prototypes to high-volume production.

Let us help you solve your friction and maintenance challenges. Contact our team today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers