While PTFE has many exceptional qualities, its most notable feature is its extremely low coefficient of friction. This property is responsible for its famous non-stick, or "slippery," character, making it one of the most lubricious solid materials known to science and the defining feature for its most common applications.

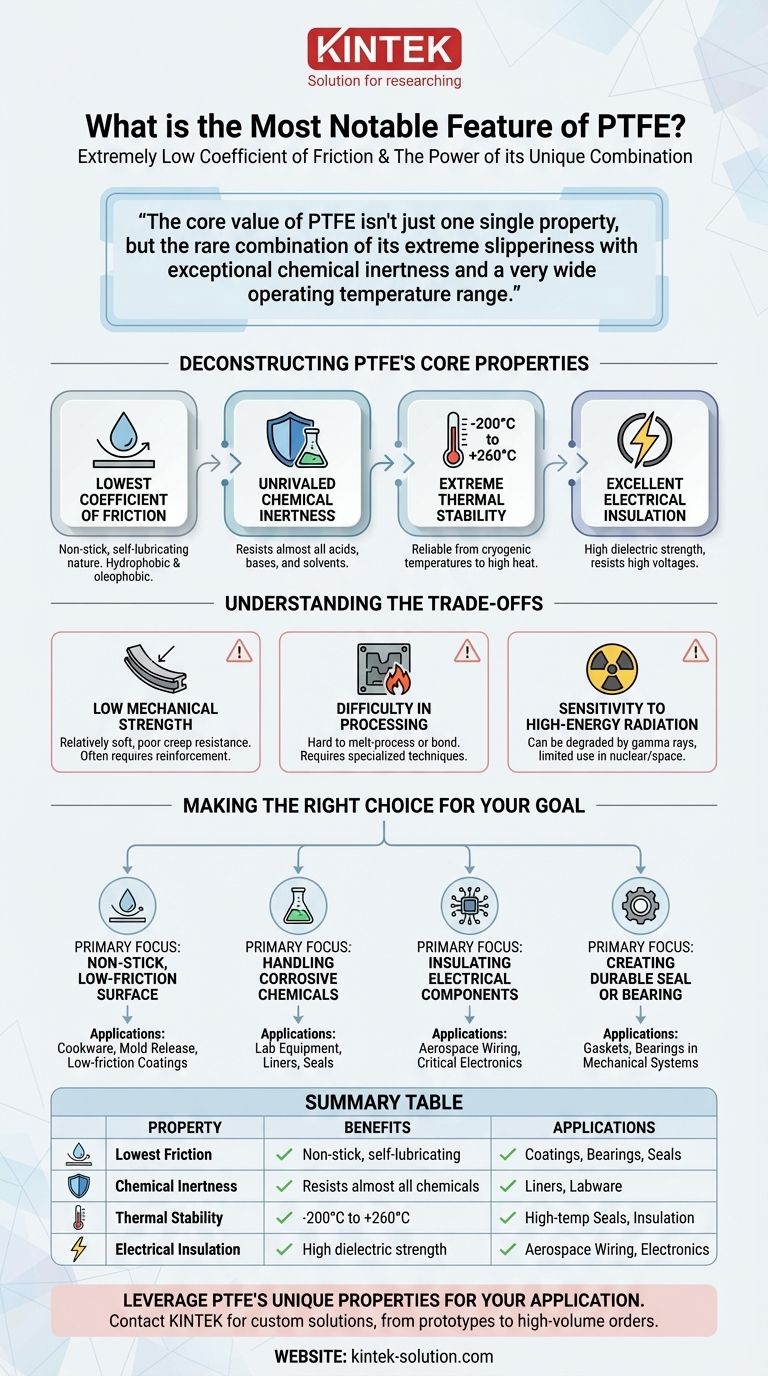

The core value of PTFE isn't just one single property, but the rare combination of its extreme slipperiness with exceptional chemical inertness and a very wide operating temperature range. This trio of characteristics makes it a uniquely powerful problem-solver in demanding environments.

Deconstructing PTFE's Core Properties

To understand what makes PTFE so versatile, it's essential to look at how its primary attributes work together. While low friction is the headline, its other features are what enable it to be used in such a wide array of applications.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material. This means that very little energy is required for another material to slide across its surface.

This property is what gives PTFE its signature non-stick and self-lubricating nature. It is inherently hydrophobic (repels water) and oleophobic (repels oil), preventing most substances from adhering to it.

Unrivaled Chemical Inertness

Another defining feature of PTFE is its near-total immunity to chemical attack. It is inert in the presence of almost all industrial chemicals, including aggressive acids, bases, and solvents.

This exceptional resistance makes it an ideal material for lining pipes, tanks, and vessels used in chemical processing, as well as for creating seals and gaskets that must withstand corrosive environments.

Extreme Thermal Stability

PTFE performs reliably across an incredibly wide temperature range, typically cited as -200°C to +260°C (-328°F to +500°F).

It retains its flexibility even at cryogenic temperatures and does not degrade at the high temperatures required for many industrial processes. This stability allows it to be used where other polymers would fail.

Excellent Electrical Insulation

PTFE is an outstanding electrical insulator with a high dielectric strength. It resists high voltages and does not conduct electricity.

This property, combined with its thermal stability, makes it a preferred choice for high-performance wire and cable insulation, especially in aerospace and computing applications where reliability is critical.

Understanding the Trade-offs

No material is perfect, and PTFE's unique strengths come with certain limitations. Understanding these trade-offs is crucial for its proper application.

Low Mechanical Strength

PTFE is a relatively soft material. It has poor resistance to creep (the tendency to slowly deform under constant stress) and is not suitable for structural applications on its own.

For this reason, it is often used as a coating, a liner, or reinforced with other materials like glass fiber or carbon to improve its mechanical properties for use in seals and bearings.

Difficulty in Processing

The same chemical inertness and high melting point (around 327°C) that make PTFE so durable also make it difficult to process. It cannot be easily melt-processed or injection-molded like common plastics.

Instead, it is typically formed into shapes using specialized techniques like compression molding and sintering. Furthermore, its non-stick surface makes it very difficult to bond to other materials using conventional adhesives.

Sensitivity to High-Energy Radiation

While resistant to many environmental factors, PTFE can be degraded by high-energy radiation, such as gamma rays. Its radiation resistance is relatively low compared to other polymers.

This limitation means it may not be suitable for certain applications within nuclear environments or space where radiation exposure is a significant concern.

Making the Right Choice for Your Goal

Selecting PTFE is about leveraging its unique combination of properties. Your primary goal will determine which of its features is most important.

- If your primary focus is creating a non-stick, low-friction surface: PTFE is an unparalleled choice for applications like cookware, industrial mold release, and low-friction coatings.

- If your primary focus is handling corrosive or high-purity chemicals: Its chemical inertness makes it the gold standard for lab equipment, chemical processing liners, and seals.

- If your primary focus is insulating electrical components: Its high dielectric strength combined with thermal stability is ideal for high-performance wiring and critical electronic parts.

- If your primary focus is creating a durable seal or bearing: Its flexibility, chemical resistance, and low-friction nature make it perfect for gaskets and bearings in demanding mechanical systems.

Ultimately, PTFE is a specialist material whose value is unlocked by understanding how its distinct properties solve specific, challenging engineering problems.

Summary Table:

| Key Property | Benefit | Common Application |

|---|---|---|

| Lowest Coefficient of Friction | Non-stick, self-lubricating surfaces | Coatings, bearings, seals |

| Unrivaled Chemical Inertness | Resists almost all acids, bases, solvents | Chemical processing liners, labware |

| Extreme Thermal Stability (-200°C to +260°C) | Reliable performance from cryogenic to high heat | High-temp seals, insulation |

| Excellent Electrical Insulation | High dielectric strength, resists high voltages | Aerospace wiring, critical electronics |

Leverage PTFE's Unique Properties for Your Application

PTFE's rare combination of extreme slipperiness, chemical inertness, and thermal stability makes it a uniquely powerful problem-solver. Whether you need custom seals, liners, labware, or components for the semiconductor, medical, laboratory, or industrial sectors, KINTEK can help.

We specialize in precision manufacturing and custom fabrication of PTFE components, from prototypes to high-volume orders. Our expertise ensures you get the right material properties for your most demanding environments.

Ready to solve your toughest engineering challenges? Contact KINTEK today to discuss your specific needs and get a quote.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What environmental resistances does PTFE offer? Unmatched Durability for Harsh Conditions

- What are the additional properties of PTFE? Beyond Non-Stick: Extreme Chemical, Thermal & Electrical Performance

- What is Teflon and what are its alternative names? Understanding PTFE, the Material Behind the Brand

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity

- How was PTFE discovered and developed? From Lab Accident to Essential High-Performance Polymer