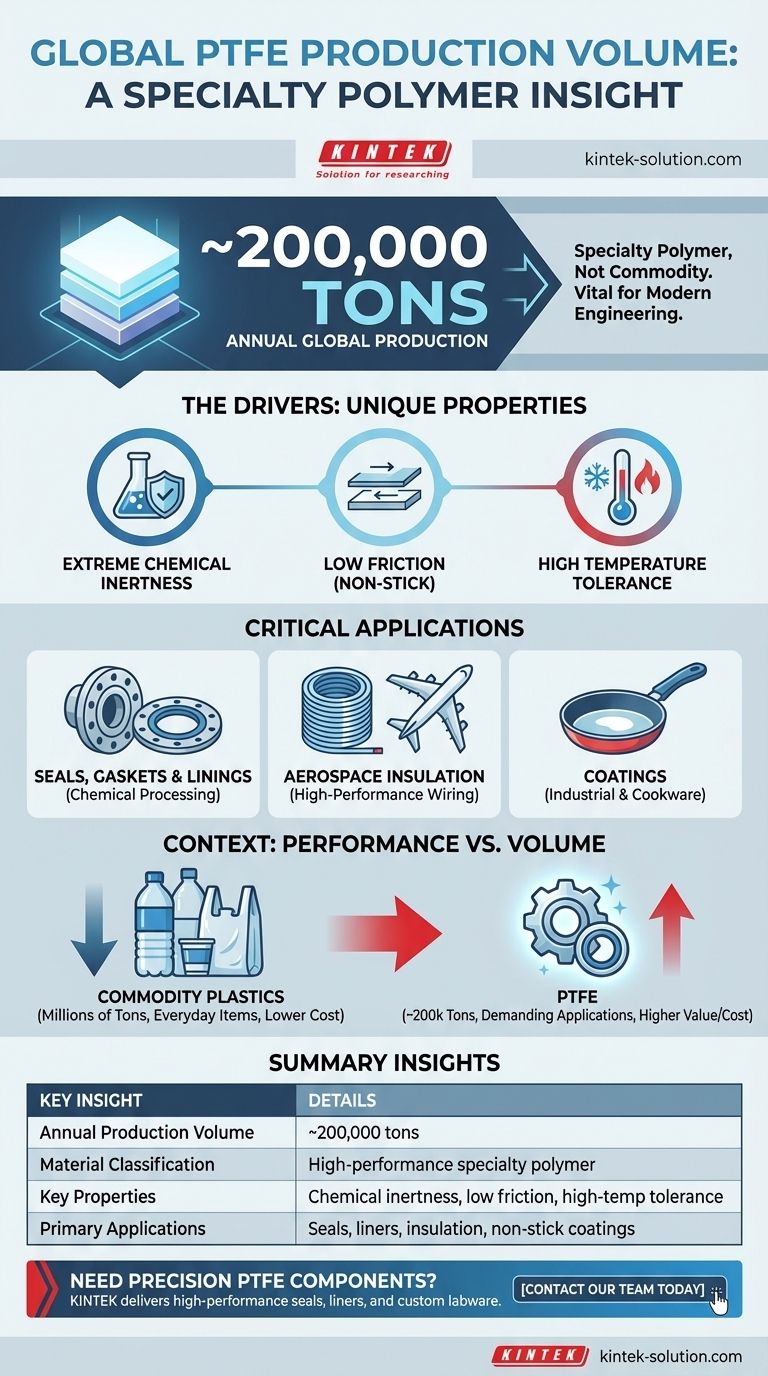

Globally, the annual production of Polytetrafluoroethylene (PTFE) is approximately 200,000 tons. This figure places PTFE in a unique category: it is not a mass-produced commodity plastic, but a high-performance polymer manufactured at a significant scale. Its production volume is a direct reflection of its unique and valuable properties that are indispensable in a wide range of demanding industrial and consumer applications.

While the number itself is straightforward, the real insight is what it reveals: PTFE is a crucial specialty material, produced at a scale that underscores its vital role in modern engineering, from aerospace to non-stick cookware.

The Drivers Behind PTFE's Production Scale

The market demand for 200,000 tons of PTFE is not accidental. It is driven by a combination of chemical and physical properties that are difficult to replicate with other materials.

The Unique Properties of PTFE

PTFE's value originates from its molecular structure. The strong carbon-fluorine bonds create a material that is exceptionally stable and non-reactive.

This results in three key characteristics: extreme chemical inertness, a very low coefficient of friction (making it famously non-stick), and a high tolerance for a wide range of temperatures.

Critical Industrial Applications

These properties make PTFE the material of choice for applications where performance and reliability are non-negotiable.

It is used for seals, gaskets, and linings in chemical processing plants, as high-performance insulation for wiring in aerospace, and as coatings for industrial equipment and consumer cookware, famously under the brand name Teflon.

A Specialized Manufacturing Process

The production of PTFE is a complex, multi-stage process, which contributes to its status as a specialty polymer.

It begins with raw materials like fluorspar, chloroform, and hydrofluoric acid. These are used to synthesize tetrafluoroethylene (TFE) gas, which is then polymerized using a catalyst to form the solid PTFE grains.

Understanding the Trade-offs

While PTFE's properties are highly desirable, the context of its production and use involves important considerations.

High-Performance vs. High-Volume

The 200,000-ton figure is substantial, but it is dwarfed by commodity plastics like polyethylene, which are produced in the tens of millions of tons.

This difference highlights PTFE's role. It is not used for disposable packaging or everyday items but is reserved for applications where its specific performance justifies its higher production cost.

Complexity and Cost

The manufacturing process is more energy-intensive and complex than that for simpler polymers. This inherent cost is a limiting factor on its production volume.

PTFE is therefore deployed strategically in components where no other material can provide the required level of chemical resistance, temperature stability, or low-friction performance.

How to Contextualize This Data

Understanding this production volume helps you make more informed decisions about material selection, market analysis, and its overall place in the world of engineering polymers.

- If your primary focus is material selection: Recognize that PTFE is an engineered solution for demanding applications where performance is the primary concern.

- If your primary focus is market analysis: View the 200,000-ton figure as an indicator of a stable, mature market for a specialty polymer with essential industrial functions.

- If your primary focus is process engineering: Appreciate that this volume is the output of a complex chemical synthesis and polymerization process reserved for creating high-value materials.

Ultimately, this production figure positions PTFE as a critical, high-performance material engineered to solve some of the toughest material science challenges.

Summary Table:

| Key Insight | Details |

|---|---|

| Annual Production Volume | ~200,000 tons |

| Material Classification | High-performance specialty polymer |

| Key Properties | Extreme chemical inertness, low friction, high-temperature tolerance |

| Primary Applications | Seals, liners, insulation, non-stick coatings for aerospace, medical, industrial, and laboratory sectors |

Need Precision PTFE Components for Your Critical Applications?

As a manufacturer of high-performance PTFE seals, liners, and custom labware, KINTEK understands the exacting standards required in the semiconductor, medical, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you receive components that deliver the unparalleled chemical resistance and reliability PTFE is known for.

Let us help you solve your toughest material challenges. Contact our team today to discuss your specific requirements.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What is PTFE commonly known as and what type of material is it? A Guide to High-Performance PTFE Properties

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity

- How does PTFE react to common solvents? Discover Its Near-Total Chemical Immunity

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers

- How was PTFE discovered and developed? From Lab Accident to Essential High-Performance Polymer