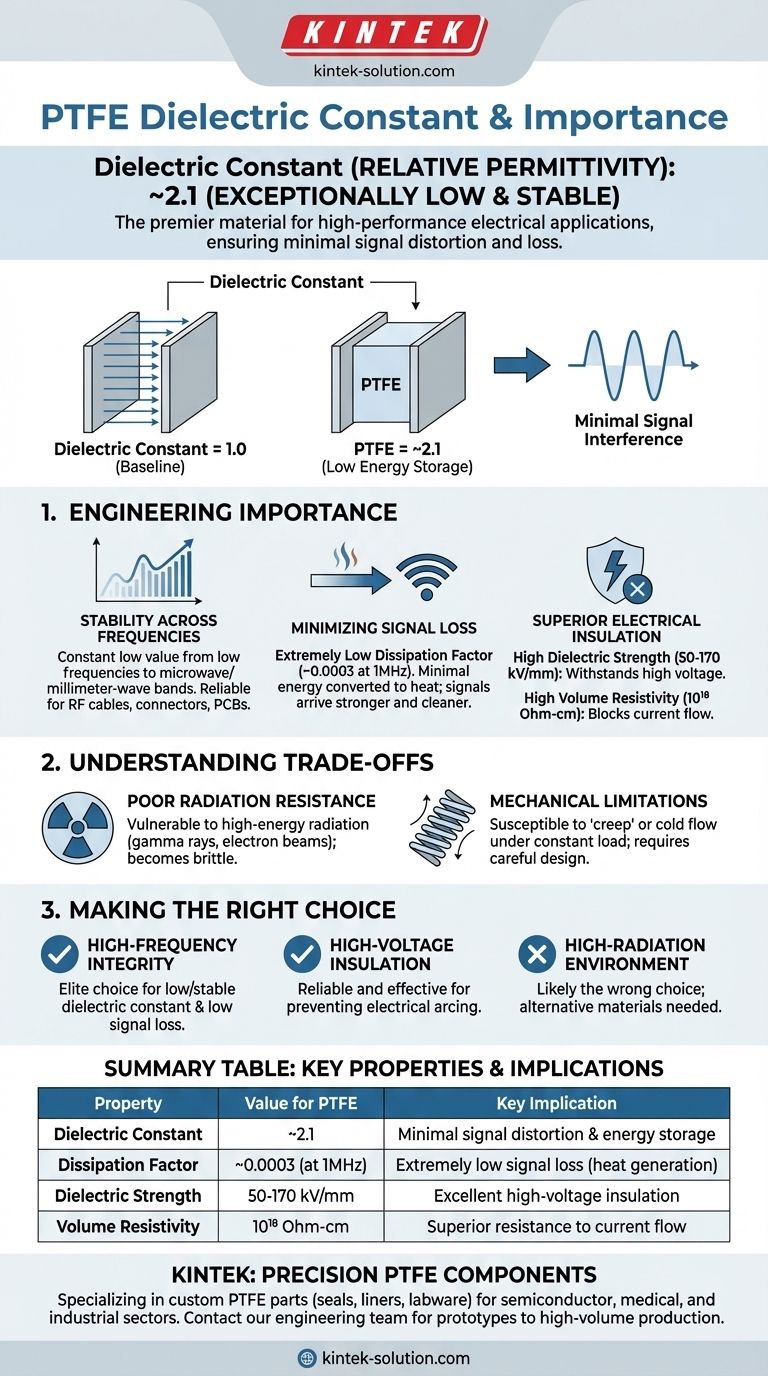

The dielectric constant of Polytetrafluoroethylene (PTFE) is approximately 2.1. This exceptionally low value, combined with its stability across a wide range of frequencies and temperatures, is precisely why it is a premier material for high-performance electrical applications. It acts as a nearly invisible insulator, allowing electrical signals to pass through with minimal distortion or loss.

The core reason PTFE is critical in advanced electronics is not just that its dielectric constant is low, but that it is consistently low. This stability ensures predictable performance, making it an elite insulator for applications where signal integrity is paramount, such as in high-frequency and microwave circuits.

Deconstructing "Dielectric Constant"

What it Fundamentally Measures

The dielectric constant, also known as relative permittivity, measures a material's ability to store electrical energy when placed in an electric field. The baseline is a perfect vacuum, which has a dielectric constant of 1.0.

A material with a higher value stores more energy, which can interfere with the electrical signal passing through or near it.

Why a Low Value is Desirable

PTFE’s low value of 2.1 means it stores very little energy from an electric field.

This property is crucial for insulation. It ensures that the insulator does not "absorb" or distort the signal in the wire it is protecting, preserving the integrity of the original transmission.

The Engineering Importance of PTFE's Properties

Stability Across Frequencies

Many materials exhibit a change in their dielectric constant as the signal frequency increases. This unpredictability can ruin the performance of a sensitive electronic circuit.

PTFE, however, maintains its low dielectric constant from low frequencies up to the microwave and millimeter-wave bands. This reliability makes it one of the most trusted materials for RF cables, connectors, and printed circuit boards (PCBs).

Minimizing Signal Loss

A material's ability to minimize signal loss is defined by its dissipation factor. PTFE’s dissipation factor is exceptionally low (around 0.0003 at 1MHz).

Combined with its low dielectric constant, this means that very little electrical energy is converted into heat and lost as the signal travels. The signal arrives at its destination stronger and cleaner.

Superior Electrical Insulation

Beyond signal integrity, PTFE is an outstanding general-purpose insulator. This is confirmed by two other key properties.

Its high dielectric strength (50-170 kV/mm) means it can withstand very high voltages before breaking down. Its high volume resistivity (10¹⁸ Ohm-cm) shows its powerful ability to block the flow of electric current.

Understanding the Trade-offs

Poor Radiation Resistance

While electrically robust, PTFE has a significant weakness: poor resistance to high-energy radiation, such as gamma rays or electron beams.

Exposure to radiation can sever the polymer chains, causing the material to become brittle and lose its structural integrity. This limits its use in nuclear or space applications where radiation tolerance is required.

Mechanical Limitations

PTFE is a relatively soft material. It is susceptible to "creep" or cold flow, meaning it can deform over time when subjected to a constant compressive load.

This mechanical property must be accounted for in designs where tight dimensional tolerances under pressure are critical.

Making the Right Choice for Your Application

Choosing a material requires balancing its electrical, mechanical, and environmental properties. PTFE is an exceptional choice for specific, demanding scenarios.

- If your primary focus is high-frequency signal integrity: PTFE is an elite choice due to its low and stable dielectric constant and extremely low signal loss.

- If your primary focus is high-voltage insulation: PTFE's high dielectric strength and resistivity make it a reliable and effective insulator for preventing electrical arcing.

- If your application exists in a high-radiation environment: PTFE is likely the wrong choice and an alternative material should be specified.

Understanding these properties empowers you to leverage PTFE's strengths where they matter most.

Summary Table:

| Property | Value for PTFE | Key Implication |

|---|---|---|

| Dielectric Constant | ~2.1 | Minimal signal distortion and energy storage |

| Dissipation Factor | ~0.0003 (at 1MHz) | Extremely low signal loss (heat generation) |

| Dielectric Strength | 50-170 kV/mm | Excellent high-voltage insulation |

| Volume Resistivity | 10¹⁸ Ohm-cm | Superior resistance to current flow |

Need high-performance PTFE components for your critical application?

KINTEK specializes in manufacturing precision PTFE parts—including seals, liners, and custom labware—for the semiconductor, medical, and industrial sectors. Our expertise ensures your components deliver the stable dielectric performance and signal integrity your designs demand.

Contact our engineering team today to discuss your custom fabrication needs, from prototypes to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability