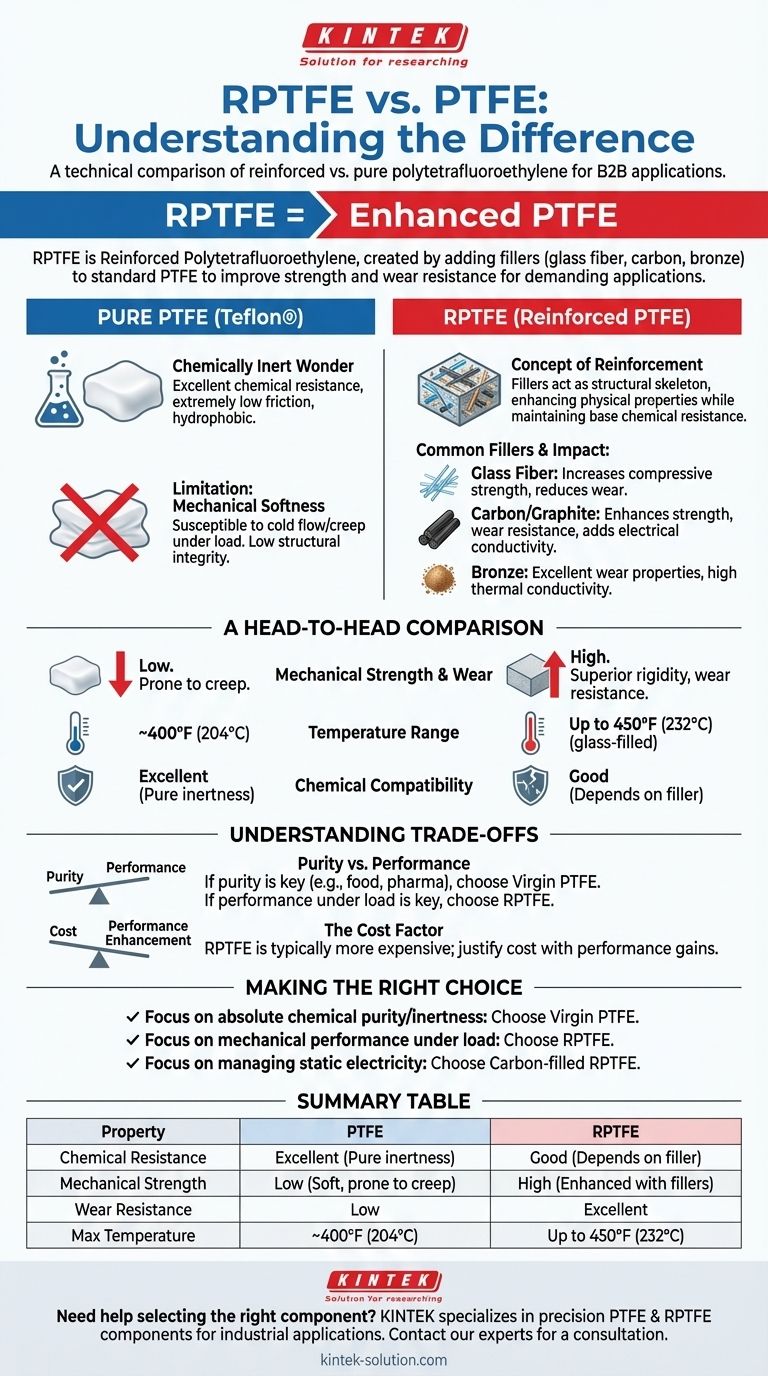

In short, RPTFE is an enhanced version of PTFE. RPTFE, or Reinforced Polytetrafluoroethylene, is a composite material created by adding fillers like glass fiber, carbon, or bronze to a base of standard PTFE. This reinforcement is done to overcome the inherent softness and deformation tendencies of pure PTFE, significantly improving its strength and wear resistance for more demanding applications.

The choice between RPTFE and PTFE is a classic engineering trade-off. While both share the same base chemical resistance and low-friction properties, RPTFE sacrifices some of PTFE's absolute chemical inertness to gain significant improvements in mechanical strength, wear resistance, and dimensional stability under load.

The Foundation: Understanding Pure PTFE

A Chemically Inert Wonder

Pure Polytetrafluoroethylene (PTFE), often known by the brand name Teflon, is a fluorocarbon polymer. It is renowned for its extreme chemical resistance, making it nearly impervious to most corrosive substances.

Its other defining features are an incredibly low coefficient of friction (making it very slippery) and hydrophobic (water-repelling) properties.

The Inherent Limitation: Mechanical Softness

The primary weakness of pure PTFE is its mechanical performance. Under sustained pressure or load, it is susceptible to "cold flow" or creep, meaning it can slowly deform and lose its shape over time.

This softness limits its use in applications requiring high structural integrity, such as high-pressure valve seats or heavy-load bearings.

The Upgrade: How RPTFE Changes the Game

The Concept of Reinforcement

To solve the problem of softness, manufacturers create RPTFE by blending the base PTFE resin with reinforcing fillers before it is molded.

These fillers act like a structural skeleton within the PTFE matrix, dramatically enhancing its physical properties without completely altering its desirable chemical characteristics.

Common Fillers and Their Impact

The choice of filler material directly tailors the RPTFE's performance for specific tasks.

- Glass Fiber: This is a common filler that significantly increases compressive strength and reduces wear and deformation under load.

- Carbon/Graphite: Adding carbon or graphite enhances strength and wear resistance even more than glass, and it can also increase electrical conductivity, which is useful for preventing static buildup.

- Bronze: This metallic filler provides excellent wear properties and high thermal conductivity but has lower chemical resistance compared to other options.

A Head-to-Head Comparison: Key Differences

Mechanical Strength and Wear

This is the most significant difference. RPTFE is far superior in strength, rigidity, and resistance to wear and deformation. Pure PTFE is soft and best suited for low-load applications.

Temperature Range

While both materials perform well across a wide range of temperatures, certain RPTFE variants can have a slightly higher maximum operating temperature. For example, some glass-filled grades are rated to 450°F (232°C), compared to 400°F (204°C) for standard PTFE.

Chemical Compatibility

Pure PTFE is the undisputed champion of chemical inertness. Because RPTFE contains fillers, its overall chemical resistance is dictated by the compatibility of the filler material itself. A highly corrosive chemical might not affect the PTFE base but could attack the glass or bronze filler within it.

Understanding the Trade-offs

Purity vs. Performance

This is the central dilemma. If your application demands absolute chemical purity and inertness—such as in food, pharmaceutical, or semiconductor manufacturing—virgin PTFE is the only choice. The introduction of any filler, no matter how small, is a potential contaminant.

However, if your component must withstand mechanical stress, pressure, or friction, the performance gains from RPTFE are non-negotiable.

The Cost Factor

Reinforced grades are typically more expensive than pure PTFE due to the additional materials and more complex manufacturing processes involved. The performance enhancement must justify the increase in cost.

Making the Right Choice for Your Application

Ultimately, the correct material depends entirely on the demands of your specific environment.

- If your primary focus is absolute chemical purity and inertness: Choose virgin PTFE, especially in applications where any filler could act as a contaminant.

- If your primary focus is mechanical performance under load: Select RPTFE, as it is specifically engineered to resist deformation and wear in dynamic applications like valve seats, bearings, or seals under pressure.

- If your primary focus is managing static electricity: Opt for a carbon-filled RPTFE, which provides a path for electrical charges to dissipate, unlike the highly insulating pure PTFE.

By understanding this fundamental trade-off between purity and performance, you can confidently select the material best engineered for your specific challenge.

Summary Table:

| Property | PTFE | RPTFE |

|---|---|---|

| Chemical Resistance | Excellent (Pure inertness) | Good (Depends on filler) |

| Mechanical Strength | Low (Soft, prone to creep) | High (Enhanced with fillers) |

| Wear Resistance | Low | Excellent |

| Max Temperature | ~400°F (204°C) | Up to 450°F (232°C) |

| Best For | Chemical purity, low-load applications | High-pressure, mechanical stress applications |

Need help selecting the right PTFE or RPTFE component for your specific application?

At KINTEK, we specialize in manufacturing precision PTFE and RPTFE components (seals, liners, labware, and more) for semiconductor, medical, laboratory, and industrial applications. Whether you require the absolute chemical purity of virgin PTFE or the enhanced mechanical performance of reinforced RPTFE, our custom fabrication services—from prototypes to high-volume orders—ensure you get the optimal material solution for your challenges.

Contact our experts today for a consultation on your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application