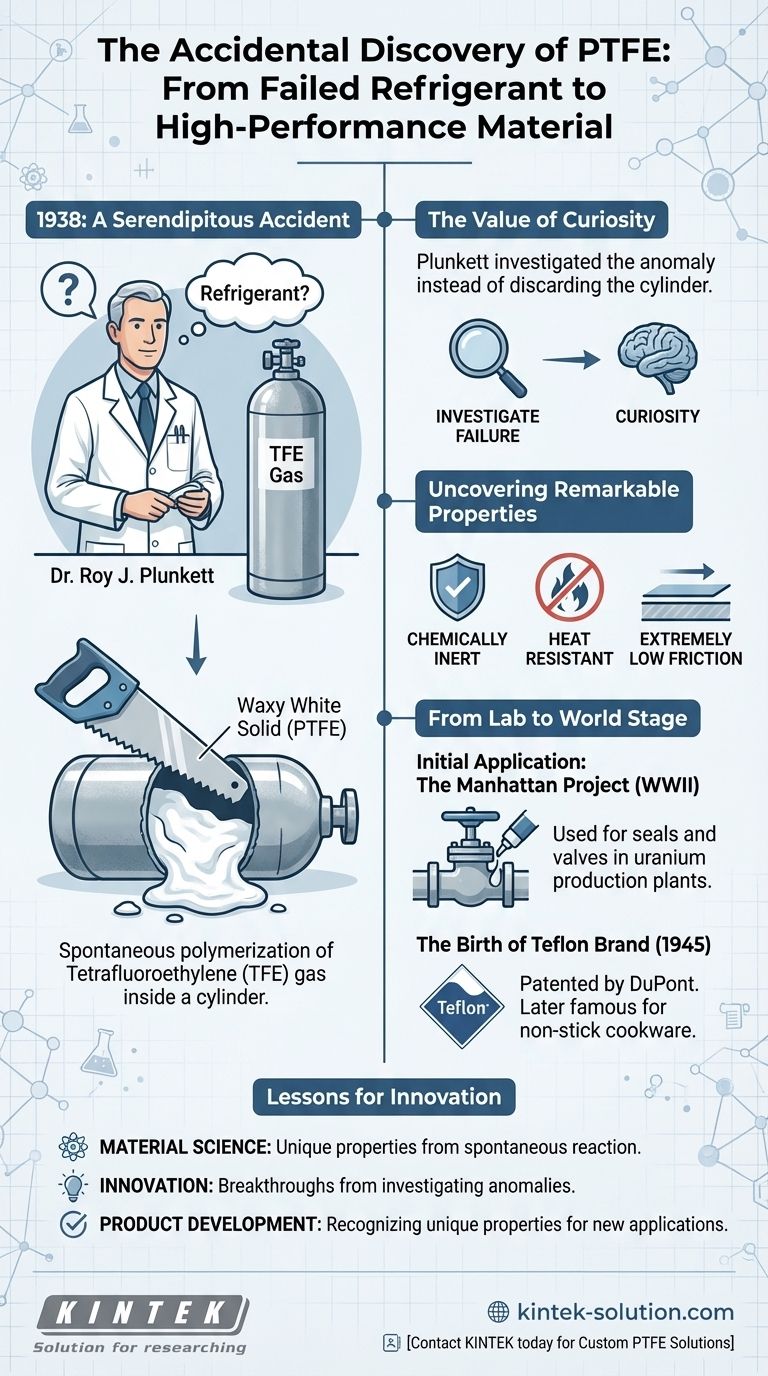

In short, Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer that was discovered entirely by accident in 1938. Dr. Roy J. Plunkett, a chemist at DuPont, was attempting to create a new, non-toxic refrigerant when one of his gas cylinders appeared to be empty despite its weight. Upon sawing it open, he found it was coated with a strange, waxy white solid that possessed incredibly slippery and heat-resistant properties.

The discovery of PTFE was not the result of a planned experiment, but a serendipitous accident. The true innovation came from Dr. Plunkett's curiosity in investigating a failed experiment, which revealed a material with a combination of properties previously unknown to science.

The Anatomy of an Accidental Discovery

The story of PTFE, best known by its trade name Teflon, is a classic example of how scientific breakthroughs can emerge from unexpected outcomes.

The Intended Goal: A Better Refrigerant

Dr. Plunkett's objective was not to create a non-stick coating. His team was working with gases related to chlorofluorocarbons (CFCs), aiming to develop a new, improved coolant gas.

The specific gas in question was tetrafluoroethylene (TFE), which was stored under pressure in small metal cylinders.

The Failed Experiment

The core of the discovery occurred when a cylinder of TFE gas stopped dispensing long before it should have been empty. The pressure gauge read zero, indicating no gas was left, yet the cylinder's weight was unchanged.

Instead of discarding the apparently faulty cylinder, Plunkett and his assistant decided to investigate the anomaly.

A Puzzling Substance

Curiosity led them to saw the metal cylinder open. Inside, they did not find residual gas but a peculiar waxy, white powder that was remarkably slippery.

The TFE gas molecules had spontaneously bonded together—a process called polymerization—to form the long, stable chains of Polytetrafluoroethylene. It is believed the iron from the inside of the container acted as a catalyst for this reaction.

From Lab Curiosity to Global Impact

The new substance was not a refrigerant, but initial tests quickly revealed it was something far more extraordinary.

Uncovering Remarkable Properties

Plunkett's team found that PTFE had a unique set of characteristics. It was extremely resistant to heat and corrosion, chemically inert, and had an incredibly low coefficient of friction, making it one of the most slippery materials known.

Initial Strategic Applications

Because of its high resistance to corrosive materials, one of PTFE's first major uses was for the Manhattan Project during World War II, where it was used to coat valves and seals in the plant producing uranium.

The Birth of the Teflon Brand

DuPont patented the substance in 1945 and registered the Teflon trademark. It would later become famous for its revolutionary application in non-stick cookware, but its use extends to aerospace, telecommunications, and medical applications.

The Principle of Serendipitous Innovation

The creation of PTFE was an accident, but its discovery was not. The event highlights a critical principle in science and engineering.

The Value of Investigating Failure

The defining moment was not the chemical reaction inside the cylinder, but Dr. Plunkett's decision to understand why his experiment had failed. Discarding the "broken" cylinder would have meant discarding the discovery entirely.

Curiosity as the Catalyst

The story serves as a powerful reminder that progress is often driven by observing the unexpected and having the curiosity to ask "Why?". Many significant inventions arise not from a linear path to a goal, but from exploring unintentional detours.

Applying the Lessons from PTFE's Discovery

The origin of this material provides insight beyond pure chemistry, offering a model for innovation itself.

- If your primary focus is on material science: The spontaneous polymerization of a simple gas molecule under pressure created a solid with a unique combination of thermal, chemical, and frictional properties.

- If your primary focus is on innovation: True breakthroughs often emerge from rigorously investigating anomalies and unexpected failures, not just from executing a plan perfectly.

- If your primary focus is on product development: A material's initial intended use may not be its most valuable one; recognizing its unique properties is key to finding its ideal application.

Ultimately, the creation of PTFE demonstrates that the most profound discoveries are often waiting in the results we didn't expect.

Summary Table:

| Key Aspect | Details |

|---|---|

| Discovery Year | 1938 |

| Discoverer | Dr. Roy J. Plunkett (DuPont) |

| Initial Goal | Create a new refrigerant gas |

| Discovery Event | Spontaneous polymerization of TFE gas in a cylinder |

| Key Properties | Heat resistant, chemically inert, extremely low friction |

| First Major Use | Seals and valves for the Manhattan Project |

Leverage the unique properties of PTFE for your critical applications.

KINTEK specializes in the precision manufacturing of high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures material integrity and exact specifications.

Contact KINTEK today to discuss how our custom PTFE solutions can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What factors should be considered when choosing between PTFE and FR4 PCB materials? Optimize Your Design for Performance and Cost.

- How is RPTFE different from standard PTFE in composition? A Guide to Enhanced Material Performance

- What are the key physical and chemical properties of PTFE? Unlock Unmatched Chemical & Thermal Resistance

- Is Teflon used in clothing or textiles? Discover the Hidden Coating That Repels Stains and Water

- How is PTFE utilized in the medical and pharmaceutical industries? Ensure Purity and Biocompatibility

- How does the molecular structure of Nylon differ from PTFE? A Guide to Polymer Properties

- Why is PTFE valuable in automotive and aerospace industries? The Ultimate Material for Extreme Environments

- What PTFE formulations are recommended for automotive and aerospace applications and why? Optimize with Bronze-Filled PTFE