In short, Expanded PTFE (ePTFE) joint sealant is a soft, rope-like material used to create custom, form-in-place gaskets directly on flanges and other sealing surfaces. It is engineered to solve sealing challenges where pre-cut gaskets fail, particularly on rough, irregular, or damaged equipment.

The core value of Expanded PTFE joint sealant is its extreme adaptability. It combines near-universal chemical inertness and a massive temperature range with the unique ability to compress and conform to surface imperfections, creating a highly reliable static seal in the most difficult industrial environments.

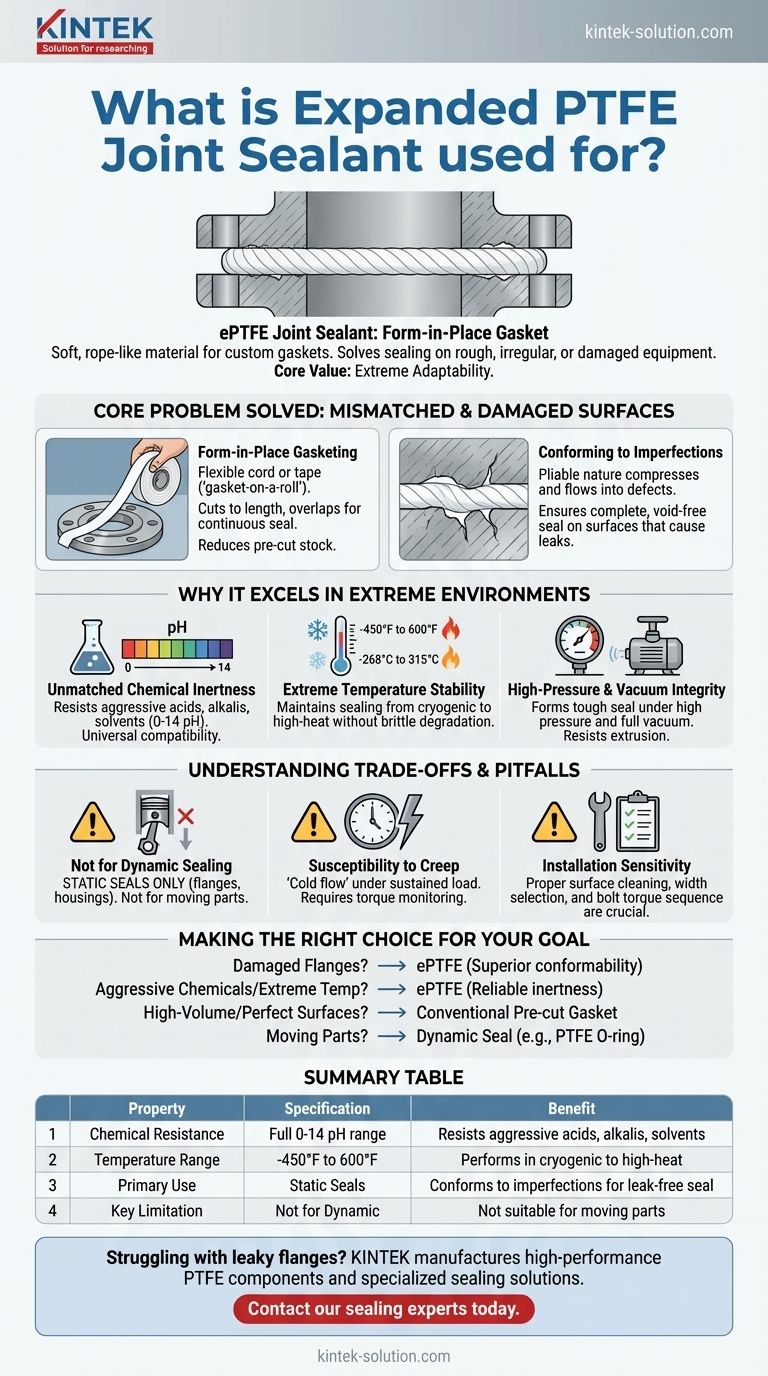

The Core Problem It Solves: Mismatched and Damaged Surfaces

Expanded PTFE joint sealant is fundamentally a problem-solver for static sealing applications that are anything but standard.

Form-in-Place Gasketing

Unlike rigid, pre-cut gaskets, ePTFE joint sealant typically comes on a spool as a flexible cord or tape. The technician applies it directly to the flange face, cuts it to length, and overlaps the ends to form a continuous seal.

This "gasket-on-a-roll" approach eliminates the need to stock numerous sizes of pre-cut gaskets, making it invaluable for maintenance and field repairs.

Conforming to Imperfections

The material's most critical feature is its soft, pliable nature. When the flange bolts are tightened, the ePTFE compresses and flows into minor scratches, pits, corrosion, and warped areas on the sealing surface.

This ensures a complete, void-free seal on surfaces that would cause a traditional gasket to leak.

Why It Excels in Extreme Environments

Beyond its physical adaptability, ePTFE is composed of a material renowned for its resilience under harsh operational conditions.

Unmatched Chemical Inertness

Expanded PTFE joint sealant is chemically resistant across the entire 0-14 pH range. This means it will not degrade when exposed to the most aggressive acids, alkalis, solvents, or process chemicals.

This universal compatibility makes it a safe, reliable choice for chemical processing, pharmaceuticals, and other industries where media purity and seal integrity are paramount.

Extreme Temperature Stability

The material maintains its sealing properties across an exceptionally wide thermal range, typically from -450°F to 600°F (-268°C to 315°C).

This allows it to be used in everything from cryogenic applications to high-temperature process lines without becoming brittle or degrading.

High-Pressure and Vacuum Integrity

Once compressed, the ePTFE forms a tough, cohesive seal that resists extrusion. It is engineered to handle the mechanical stresses of high-pressure fluid lines and can even be used to reliably seal joints under a full vacuum.

Understanding the Trade-offs and Common Pitfalls

While highly effective, ePTFE joint sealant is not a universal solution. Understanding its limitations is key to using it correctly.

It Is Not for Dynamic Sealing

This material is designed exclusively for static seals, such as pipe flanges, pump housings, and equipment access doors.

It should never be used in dynamic applications involving moving parts. For those scenarios, specialized seals like PTFE O-rings or piston seals are required to handle the friction and motion inside hydraulic or pneumatic systems.

Susceptibility to Creep

Like all PTFE-based materials, ePTFE can be subject to "creep" or "cold flow" over time—a slow deformation under sustained compressive load, especially at elevated temperatures. While modern formulations are designed to minimize this, it's a factor to consider in critical, high-pressure applications that require consistent bolt torque.

Installation Sensitivity

The reliability of the final seal is highly dependent on proper installation. The surface must be clean, the correct sealant width must be chosen for the flange size, and bolts must be tightened to the correct torque in the proper sequence. Improper installation can easily lead to failure.

Making the Right Choice for Your Goal

Select your sealing material based on the specific demands of the application.

- If your primary focus is sealing old, warped, or damaged flanges: Expanded PTFE joint sealant is the ideal choice due to its superior ability to conform to imperfections.

- If your primary focus is handling aggressive chemicals or extreme temperatures: This material's inertness and wide thermal range make it one of the most reliable options available.

- If your primary focus is a high-volume, standardized application with perfect surfaces: A conventional pre-cut gasket may be a more efficient and cost-effective solution.

- If your primary focus is sealing a moving part (like a piston or rotating valve stem): You must use a dynamic seal, such as a PTFE O-ring or a dedicated piston seal, not joint sealant.

Ultimately, Expanded PTFE joint sealant is the definitive solution for creating a reliable, static seal in the most demanding and imperfect conditions.

Summary Table:

| Property | Specification | Benefit |

|---|---|---|

| Chemical Resistance | Full 0-14 pH range | Resists aggressive acids, alkalis, and solvents |

| Temperature Range | -450°F to 600°F (-268°C to 315°C) | Performs in cryogenic to high-heat applications |

| Primary Use | Static Seals (flanges, housings) | Conforms to surface imperfections for a leak-free seal |

| Key Limitation | Not for Dynamic Sealing | Not suitable for moving parts like pistons or rods |

Struggling with leaky or damaged flanges? KINTEK manufactures high-performance PTFE components, including specialized sealing solutions for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a seal that meets your exact operational demands.

Contact our sealing experts today to discuss how we can solve your specific sealing challenge.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications