At its core, a PTFE sliding rubber bearing pad is a composite component designed for large-scale construction. It combines a load-bearing laminated rubber pad with an exceptionally low-friction PTFE top layer. Its primary use is in structures like bridges and large buildings to simultaneously support immense vertical weight while allowing for controlled horizontal movement.

The central challenge in large-scale construction is managing two opposing forces: the immense, static weight of the structure and the dynamic, subtle movements caused by temperature change, material creep, or seismic activity. A PTFE sliding bearing solves this by pairing the compressive strength of rubber with the near-frictionless surface of PTFE, allowing structures to "breathe" without compromising their integrity.

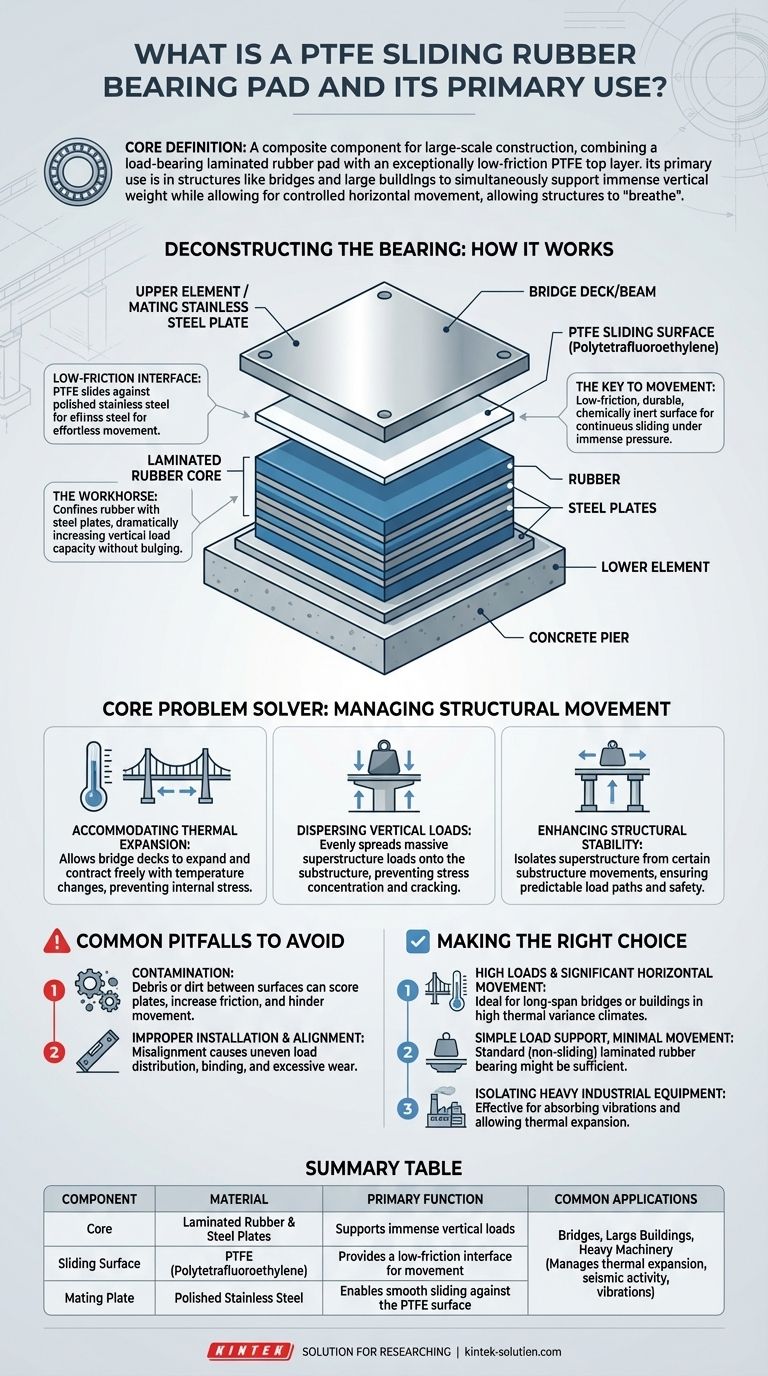

Deconstructing the Bearing Pad: How It Works

To understand its function, you must see the bearing not as a single block, but as a sophisticated, multi-layered system where each component has a distinct role.

The Laminated Rubber Core

The foundation of the bearing is a laminated elastomeric (rubber) pad. This is not solid rubber, but rather alternating layers of rubber and steel plates bonded together.

The steel plates confine the rubber, dramatically increasing its ability to support heavy vertical loads without bulging. This core is the workhorse for bearing the structure's weight.

The PTFE Sliding Surface

Bonded to the top of the rubber core is a thin sheet of PTFE (Polytetrafluoroethylene). This is the key to accommodating movement.

PTFE is a fluoropolymer known for having one of the lowest coefficients of friction of any solid. It is extremely slippery, durable, chemically inert, and resistant to corrosion, making it an ideal surface for continuous, low-friction sliding under immense pressure.

The Mating Stainless Steel Plate

The PTFE surface does not slide against concrete or steel directly. It moves against a highly polished stainless-steel plate, which is part of a separate upper element anchored to the structure's beam or girder.

The combination of PTFE sliding against polished stainless steel creates the exceptionally low-friction interface that allows for effortless movement.

The Complete Assembly

The system consists of two primary parts: a lower element (the rubber pad with its recessed PTFE surface) and an upper element (a steel plate with the polished stainless-steel sliding surface welded to it).

The lower element is placed on the foundation or pier, while the upper element is fixed to the bridge deck or building beam. The structure can then slide smoothly on the PTFE surface.

The Core Problem It Solves: Managing Structural Movement

Large structures are not static; they are constantly in motion. These bearings are engineered solutions to manage this reality safely.

Accommodating Thermal Expansion

The most common source of movement is thermal expansion and contraction. As temperatures rise and fall, a long bridge can change in length by several inches or even feet.

The PTFE sliding bearing allows the bridge deck to expand and contract freely, preventing the buildup of immense internal stress that could otherwise damage the support piers and abutments.

Dispersing Vertical Loads

The rubber core’s primary job is to disperse the massive vertical loads from the superstructure evenly onto the substructure.

This prevents the concentration of stress, which could lead to cracking and structural failure in the concrete piers over time.

Enhancing Structural Stability

By isolating the superstructure from certain movements of the substructure, these bearings enhance overall safety and stability.

They allow for small, controlled movements and rotations, ensuring the loads are always transferred predictably through their intended paths.

Common Pitfalls to Avoid

The performance of these bearings depends entirely on their correct design and installation. Errors can undermine their effectiveness.

Contamination of Sliding Surfaces

The low-friction properties of the PTFE and stainless-steel interface are highly sensitive to contamination.

Debris, dirt, or grit trapped between the surfaces can score the plates, increase friction, and hinder movement. Proper sealing and protection during and after construction are critical.

Improper Installation and Alignment

The sliding surfaces must be installed perfectly level and parallel.

Any misalignment can cause the load to be distributed unevenly, leading to binding, excessive wear on one edge of the PTFE pad, and a failure to accommodate movement as designed.

Making the Right Choice for Your Application

Selecting the right bearing depends on the specific demands of the structure.

- If your primary focus is supporting high loads with significant horizontal movement: The PTFE sliding rubber bearing is the ideal choice, perfectly suited for long-span bridges or buildings in climates with large temperature swings.

- If your primary focus is simple load support with minimal movement: A standard (non-sliding) laminated rubber bearing pad may be a more cost-effective and sufficient solution.

- If your primary focus is isolating heavy industrial equipment: These bearings are also highly effective for factory machinery, where they can absorb vibrations and allow for thermal expansion of the equipment base.

Ultimately, this component is a critical enabler of modern, resilient construction, allowing massive structures to stand strong while adapting to their environment.

Summary Table:

| Component | Material | Primary Function |

|---|---|---|

| Core | Laminated Rubber & Steel Plates | Supports immense vertical loads |

| Sliding Surface | PTFE (Polytetrafluoroethylene) | Provides a low-friction interface for movement |

| Mating Plate | Polished Stainless Steel | Enables smooth sliding against the PTFE surface |

| Common Applications | Bridges, Large Buildings, Heavy Machinery | Manages thermal expansion, seismic activity, and vibrations |

Need High-Performance PTFE Components for Your Critical Applications?

At KINTEK, we specialize in the precision manufacturing of PTFE components, including seals, liners, and custom parts for demanding industries like construction, semiconductor, medical, and laboratory. Our expertise ensures the durability and low-friction performance essential for components like sliding bearing pads.

We offer custom fabrication from prototypes to high-volume orders, guaranteeing the quality and reliability your projects demand.

Contact our experts today to discuss your specific requirements and discover how KINTEK can support your next project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers