In simple terms, a PTFE cylindrical bush is a high-performance sleeve, or bearing, made from a fluoropolymer called Polytetrafluoroethylene (PTFE). It takes the form of a straight, hollow cylinder and is engineered to enable smooth rotational or linear movement between machine parts, particularly in applications where low friction, chemical resistance, and temperature tolerance are critical.

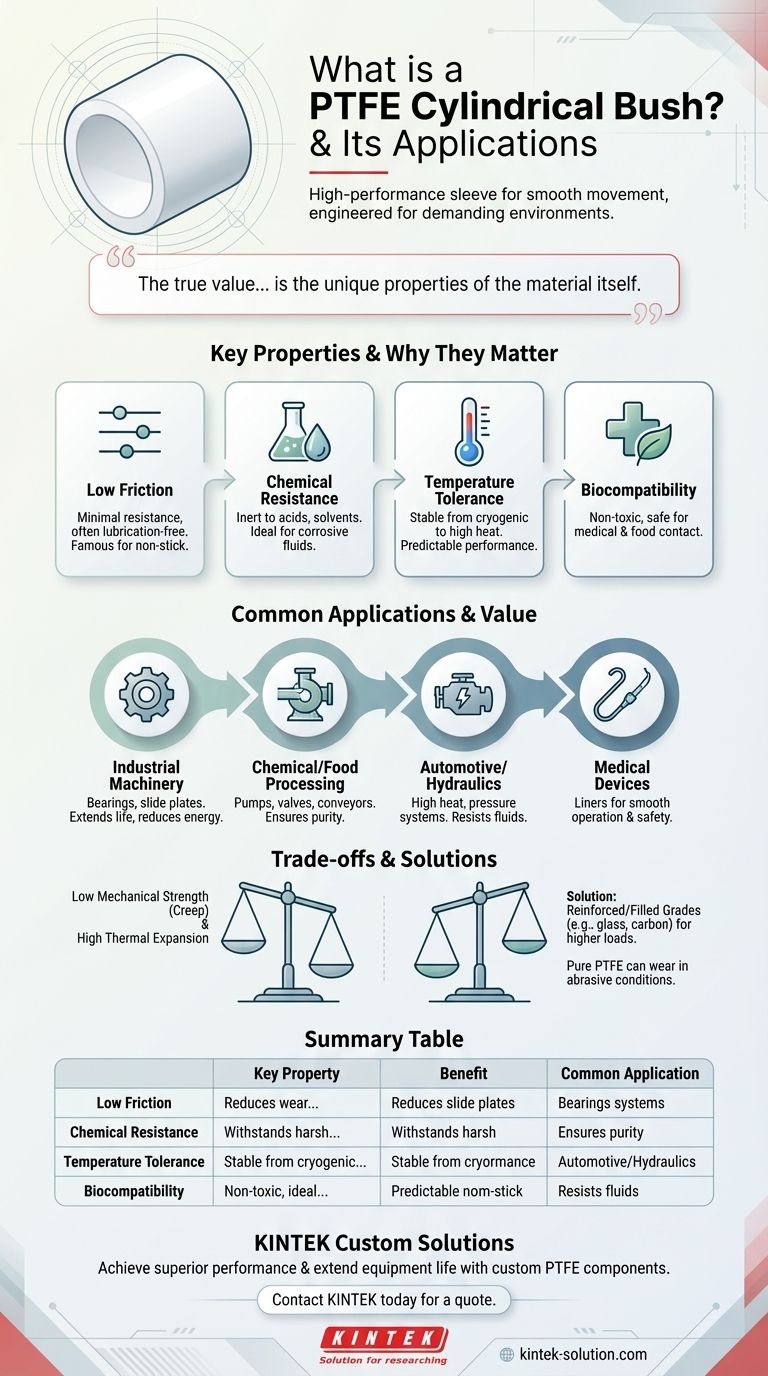

The true value of a PTFE bush is not its simple shape, but the unique properties of the material itself. Its exceptionally low friction, chemical inertness, and resistance to extreme temperatures make it the superior choice for demanding industrial, medical, and automotive applications.

What Makes PTFE the Ideal Material for Bushings?

A bushing's primary job is to reduce friction and wear between two moving parts. While many materials can serve this purpose, PTFE is chosen when the operating environment is too demanding for conventional plastics or metals.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material known. This inherent "slipperiness" is why it's famous for non-stick cookware.

In a mechanical context, this means parts can slide or rotate with minimal resistance and often without the need for external lubrication, reducing maintenance and system complexity.

Extreme Chemical Resistance

PTFE is almost entirely chemically inert, meaning it does not react with the vast majority of industrial chemicals, acids, and solvents.

This non-reactivity makes it indispensable in environments like chemical processing plants or hydraulic systems where components are constantly exposed to corrosive fluids.

Wide Temperature Tolerance

This material maintains its properties across a broad temperature range. It remains stable and functional in high-temperature applications like engine components and cryogenic applications alike.

This thermal stability ensures predictable performance where other materials would degrade, melt, or become brittle.

Biocompatibility and Purity

For medical and food-grade applications, PTFE is a trusted choice because it is non-toxic and does not contaminate its environment.

Its smoothness and biocompatibility are critical for use in medical devices like catheters, where it reduces the risk of tissue damage and infection.

Where Are These Properties Most Valuable?

The combination of these characteristics makes PTFE cylindrical bushes a versatile component used across numerous high-stakes industries.

Industrial Machinery and Manufacturing

In general machinery, these bushes are used as bearings, slide plates, and gears. The low friction reduces wear on critical components, extending the life of the equipment and reducing energy consumption.

Chemical and Food Processing

Due to its chemical inertness and non-toxic nature, PTFE is used in pumps, valves, gaskets, and on conveyor rollers. It ensures that the product—be it a harsh chemical or a food item—remains pure and un-contaminated.

Automotive and Hydraulic Systems

Bushings in these systems must withstand heat, high pressure, and contact with aggressive hydraulic fluids or fuels. PTFE's thermal and chemical resistance makes it a natural fit for these demanding conditions.

Medical and Pharmaceutical Devices

The material's smoothness and biocompatibility are vital for devices that come into contact with the human body. It is commonly used as a liner in catheters and other delivery systems to ensure smooth operation and patient safety.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. An objective assessment requires understanding its limitations.

Relatively Low Mechanical Strength

Compared to metals or harder engineering plastics, PTFE is a relatively soft material. Under a constant, heavy load, it can be susceptible to "creep," a slow deformation over time. It is not ideal for high-load structural applications without reinforcement.

Higher Thermal Expansion

PTFE expands and contracts with temperature changes more significantly than metals. This must be accounted for in precision designs to maintain critical tolerances during operation.

Wear Resistance

While its low friction reduces wear on mating parts, pure PTFE itself can wear down in high-speed, abrasive conditions. For these applications, "filled" grades of PTFE (mixed with materials like glass, carbon, or bronze) are used to enhance durability.

Making the Right Choice for Your Application

Selecting the right material is about matching its properties to your primary goal.

- If your primary focus is reducing friction in a clean, low-load environment: A standard PTFE bush is an excellent, cost-effective choice for smooth sliding or rotational motion.

- If your primary focus is operation within harsh chemical or food-grade environments: PTFE's chemical inertness and purity make it one of the safest and most reliable materials available.

- If your primary focus is high-load mechanical performance or abrasive conditions: You should consider a filled or reinforced grade of PTFE to achieve the necessary strength and wear resistance.

Understanding these core material properties allows you to select a PTFE bush not just for what it is, but for the specific problem it is engineered to solve.

Summary Table:

| Key Property | Benefit | Common Application |

|---|---|---|

| Low Friction | Reduces wear, often lubrication-free | Slide plates, bearings |

| Chemical Resistance | Withstands harsh acids and solvents | Chemical processing pumps, valves |

| Temperature Tolerance | Stable from cryogenic to high heat | Automotive, hydraulic systems |

| Biocompatibility | Non-toxic, ideal for sensitive uses | Medical catheters, food processing |

Need a High-Performance PTFE Component?

PTFE cylindrical bushes are just one example of how KINTEK's precision manufacturing solves complex motion and sealing challenges. We specialize in custom-fabricated PTFE components—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors.

Let us help you:

- Achieve superior performance with low friction and extreme chemical resistance.

- Extend equipment life and reduce maintenance in demanding environments.

- Get a custom solution tailored to your exact specifications, from prototype to high-volume production.

Contact KINTEK today to discuss your application and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions